COMMENTARY

The period of clever operations is already right here, however some operational cybersecurity processes have been left previously. Because the oldest members of Gen Z begin their careers, they’re bringing new expectations for digital experiences into the office. This pattern has necessary and promising implications for operational expertise (OT) safety that may drive organizations to turn into safer, resilient, and environment friendly.

Till now, signing into OT techniques utilized in manufacturing, power, and significant infrastructure industries has typically been a gradual, cumbersome course of that is not significantly safe. OT techniques — some with decades-old expertise — use industrial protocols with restricted safety capabilities and weak distant entry protocols. These legacy elements have restricted person entry administration capabilities that require further entry administration options. The result’s that licensed customers should full further authentication steps, typically with completely different credentials, to realize entry.

Why is that this nonetheless the case in an age of facial and fingerprint recognition? In brief, the system has been maintained by extra skilled workers, so nobody noticed a cause to alter it. But as youthful staff come onboard, the legacy techniques are out of step with their era’s expertise habits, expertise, and expectations. Organizations that step as much as deal with their wants can see a number of advantages.

Higher Worker Expertise Can Enhance Retention

Workers who’re pissed off or confused by legacy safety processes are much less more likely to be totally engaged with their work and extra more likely to give up. That is very true of youthful staff. Half of Gen Z staff say they’re going to give up a job that gives poorly functioning or outdated expertise.

Bettering retention charges can at all times assist firms management prices, however in as we speak’s manufacturing sector, worker retention is extra pressing. Greater than 80% of producers reported labor shortages in 2023, and onboarding new and contractor personnel requires investing in specialised coaching, distinctive processes, security, and operational effectivity. By beginning to modernize OT safety processes and practices now, producers can acquire a aggressive recruitment and retention edge with youthful, expert staff, in comparison with firms that take a wait-and-see strategy.

Enhanced Safety, Security, and Compliance

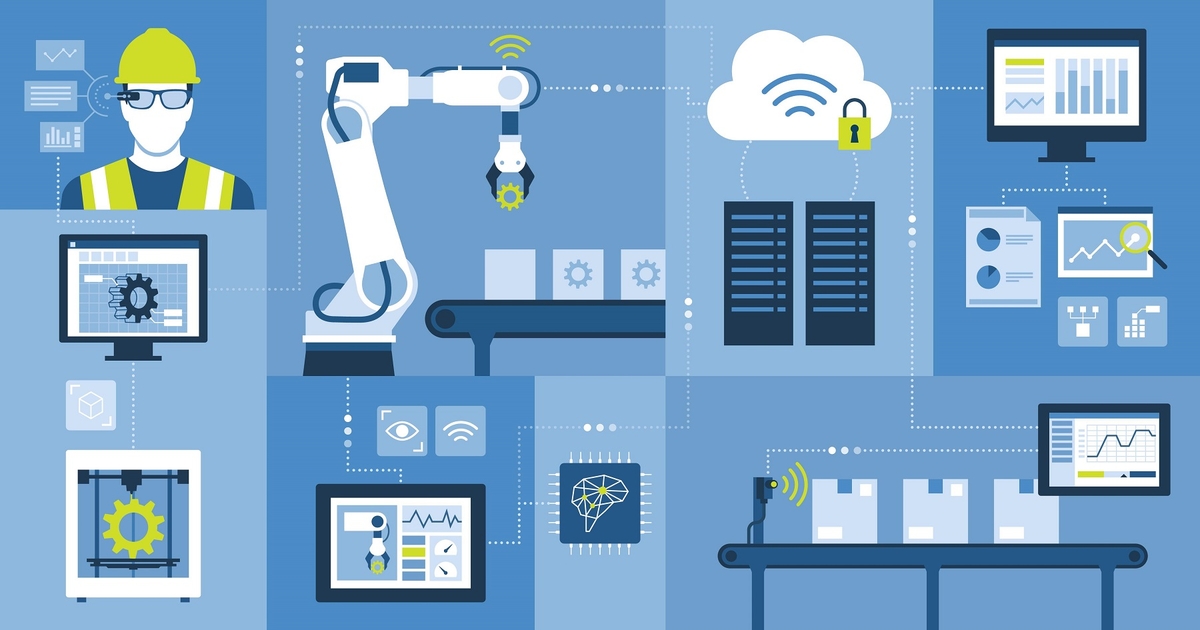

Good-factory transformation — utilizing industrial Web of Issues (IoT), cloud computing, Business 4.0, and OT-IT convergence — helps quicker, extra frequent person entry periods. This will increase the necessity to allow distant entry to crucial information and gadgets to distant staff and third events. It additionally creates new entry patterns that require extra superior entry administration options, comparable to fine-grained least-privilege entry.

Bettering entry management is crucial for operations and security. Incidents like repeated cyberattacks on nationwide energy grids and even shopper packaged items (CPG) vegetation have proven that legacy safety practices are now not sufficient to guard OT techniques, particularly now that OT and IT are inextricably linked. Excessive-profile targets aren’t the one ones to expertise assaults like these; in 2021, 73% of organizations with smart-factory operations reported at the least one cyberattack inside the earlier 12 months.

Whereas cybersecurity must broaden to watch and shield OT gear and techniques, staff additionally should be linked and visual. For instance, safety-critical jobs like refinery and oil rig work can monitor staff’ location and well being standing in actual time. That monitoring requires automated id authentication and geolocation, together with entry to non-public well being info and different delicate information.

Complete, streamlined cybersecurity is necessary for these sorts of functionalities, information safety, compliance, and higher person expertise. Apart from enhancing worker expertise and making work simpler for tech-savvy workers, improved safety processes can scale back information leakage and downtime attributable to entry friction and time spent ready for credentials.

Constructing a Fashionable OT Cybersecurity Program

Based mostly on information gathered from OT safety leaders throughout various industries, organizations with essentially the most mature OT cybersecurity packages comply with a constant set of greatest practices. These begin with assessing the group’s full cybersecurity profile to determine areas that want enchancment.

Subsequent, these organizations nurture a tradition of consciousness round cybersecurity threats to smart-factory and converged enterprise and OT operations. As a result of there are such a lot of potential factors of entry for threats, security is an all-hands effort that’s typically instantly associated to security.

With a rising tradition of safety and a set of cybersecurity benchmarks, a corporation is able to determine who owns threat administration for OT cyberattacks. It is also prepared to use a framework comparable to NIST or MITRE ATT&CK to defensive controls that monitor cybersecurity and determine areas for enchancment. Participation in trade intelligence-sharing teams comparable to MFG-ISAC can even assist organizations study new threats to the sector as they emerge. Threat homeowners can then use trade information with a confirmed framework to implement the suitable defensive controls for his or her converged OT/IT environments.

Lastly, mature OT cybersecurity requires complete governance, oversight, and periodic assessments to assist safety instruments, processes, and entry preserve tempo with the evolving risk panorama — and with worker wants and expectations.

Ahead-Trying OT Safety Helps Future Innovation

As Gen Z expectations immediate employers to enhance and replace OT safety, they’re additionally serving to transfer trade towards new capabilities. As OT, IT, IoT, and different infrastructures proceed to converge and leverage rising applied sciences, organizations can have new alternatives for extra course of automation, smart-factory and constructing innovation, and provide chain optimization. All these modifications require the type of trendy, environment friendly, user-friendly safety processes that Gen Z expects.