US-based pure fuel service supplier Upwing Vitality has leveraged know-how from metallic 3D printer producer Velo3D to 3D print its Subsurface Compressor System (SCS) compressor module.

Through the use of Velo3D’s Laser Powder Mattress Fusion (LPBF) 3D printer, Upwing has lowered the manufacturing time wanted to help its SCS fuel nicely deployment schedules.

3D printing has enabled the corporate to go from engineering design, to full compressor rotor meeting manufacturing in simply 10 weeks. Furthermore, checks which simulated the setting of the fuel compression course of highlighted the high-quality and sturdiness of the 3D printed components.

“All of our work at Upwing is underscored by the idea that steady enchancment is all the time potential,” commented Robert McKeirnan, Vice President of Provide Chain and Exterior Manufacturing at Upwing Vitality.

“Our determination to combine additive manufacturing makes us extra scalable and adaptable. It permits us to create components that aren’t solely sturdy, however intricately designed and completed with the very best stage of precision.”

Optimizing SCS compressor module manufacturing

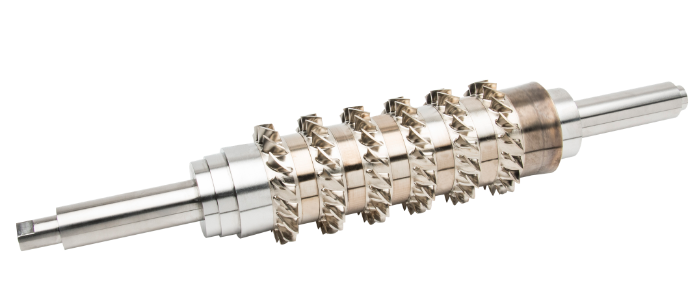

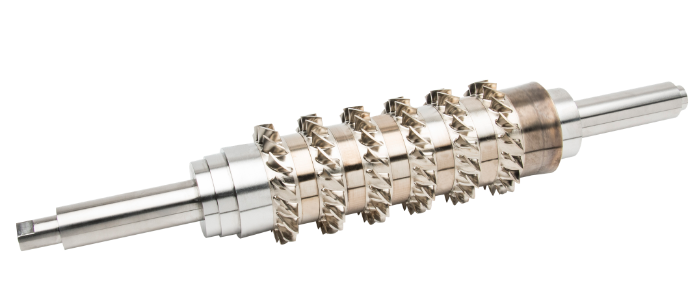

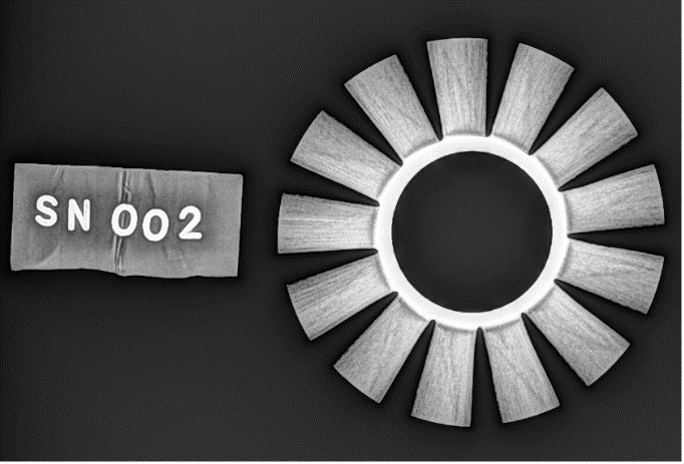

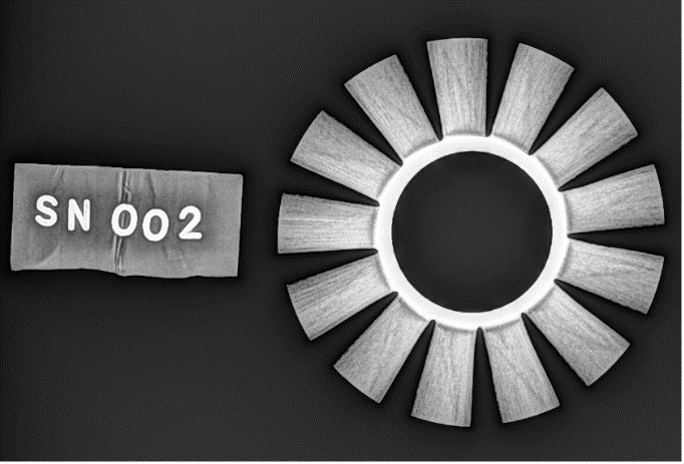

Manufactured from Inconel 718, Upwing’s proprietary SCS compressor module is designed to extend the manufacturing and recoverability of pure fuel from present wells. To attain this, the SCS includes a multistage hybrid axial compressor, which will increase drawdown on the consumption and boosts stress on the discharge.

The corporate’s SCS compressor module incorporates an aerodynamic design to match well-specific move parameters, permitting for max manufacturing achieve. In accordance with Upwing Vitality, the manufacturing of the compressor’s rotor design is very difficult resulting from its advanced floor geometries.

Along with notable lead time financial savings, Velo3D’s metallic 3D printing know-how reportedly allows the creation of extra intricate designs than standard manufacturing strategies. What’s extra, the 3D printed elements function geometric and supplies advantages, leading to improved efficiency and elevated half lifecycle.

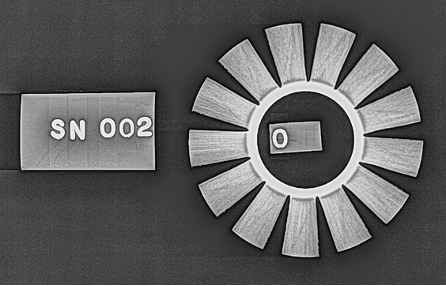

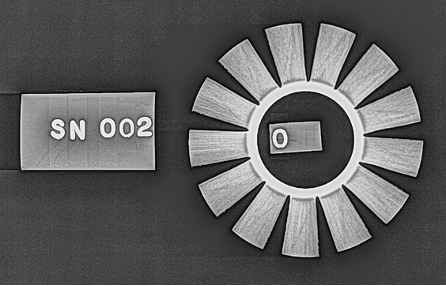

Tensile testing has demonstrated that additively manufactured Inconel 718 components meet ASTM F3055 requirements. Downhole compressor-specific necessities are additionally reportedly met by 3D printed Inconel 718.

In the course of the SCS improvement course of, the mechanical properties of 3D printed elements have been in comparison with these produced via machined billet, a typical industrial manufacturing methodology. Right here, numerous checks simulating circumstances discovered within the SCS’s fuel compression course of have been carried out.

Each 3D printed and machined billet-produced components have been examined at rotational speeds of 55K RPM or larger, the operational overspeed for the SCS. Detailed inspection was then carried out on the components. This included the usage of dye penetrant to show floor defects, steadiness checks, and dimension precision inspections. Lastly, a spin-to-burst check was carried out to validate the integrity of every manufacturing methodology.

Finally, the additively manufactured components efficiently endured the usual working circumstances of the fuel compression course of, exceeding overspeed circumstances by 2.1 instances earlier than failure.

Bolstering the oil and fuel sector with AM

Using additive manufacturing throughout the oil and fuel trade is rising, with corporations leveraging industrial 3D printing for a variety of functions.

Certainly, this isn’t the primary time that know-how from Velo3D has been utilized inside this sector. Earlier this yr, Schoeller-Bleckmann Oilfield Know-how (SBOT) bought a Velo3D Sapphire XC large-format 3D metallic printer.

Calibrated for Inconel 718, the Sapphire XC is getting used to fulfill rising demand for 3D printed components from SBOT’s prospects. Due to its geometric design flexibility, Velo3D’s 3D printer facilitates the manufacturing of intricate, mission vital components for oil and fuel functions.

Elsewhere, UK industrial valve provider KOSO Kent Introl (Kent Introl) collaborated with world engineering agency Renishaw to evaluate the benefits supplied by additive manufacturing in oil and fuel.

Kent Introl put in a Renishaw RenAM 500Q Flex 3D printer at its Brighouse, West Yorkshire HQ. The corporate claims to be the primary UK producer within the oil and fuel trade to undertake additive manufacturing. The metallic 3D printer is presently getting used for R&D functions, in addition to the fast manufacturing of components to rapidly meet buyer calls for.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of out there roles and kickstart your profession.

Featured picture exhibits Oil drilling in an oil subject. Picture by way of UTSA.