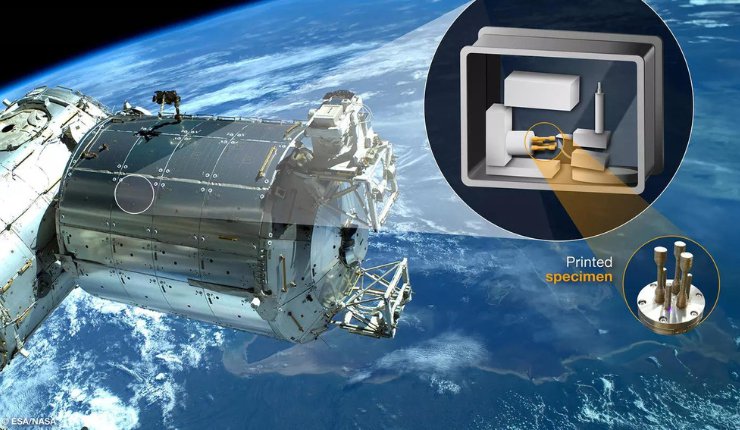

Airbus and AddUp have developed for the European Area Company (ESA) what the businesses say is the primary metallic 3D printer for area. The system will quickly be examined aboard the Columbus module of the Worldwide Area Station (ISS). Based on Airbus, the printer may very well be a “actual recreation changer” for manufacturing in area and future missions to the Moon or Mars.

The undertaking, often known as “Metal3D” started in 2016 when the ESA awarded the contract to Airbus Defence & Area. A key goal was to create the primary metallic 3D printer to function beneath microgravity, aboard the Worldwide Area Station. AddUp has been supporting the Airbus group for over a decade with a provide of flight elements, but in addition on a spread of innovation tasks.

There are already a number of polymer 3D printers on board the ISS, the primary of which arrived in 2014. Astronauts have already used the programs to switch or restore plastic elements, since one of many main problems with on a regular basis life in area is the provision of kit, which may take months to reach.

Airbus says this logistical constraint will intensify on future Moon and Mars stations within the subsequent few a long time. Even by means of uncooked materials nonetheless must be launched, printing the half continues to be extra environment friendly than transporting it complete as much as its closing vacation spot.

“The metallic 3D printer will deliver new on-orbit manufacturing capabilities, together with the likelihood to provide load-bearing structural elements which are extra resilient than a plastic equal,” stated Gwenaëlle Aridon, Airbus Area Meeting Lead Engineer. “Astronauts will have the ability to straight manufacture instruments corresponding to wrenches or mounting interfaces that would join a number of elements collectively. The pliability and fast availability of 3D printing will tremendously enhance astronaut’s autonomy.”

Whereas the method of 3D printing has been “mastered” on Earth, 3D printing metallic in area presents its personal set of technical challenges. Sébastien Girault, Metallic 3D Printer System Engineer at Airbus defined: “The primary problem with this expertise was measurement. On Earth, present metallic 3D printers are put in in a minimal ten sq. metre laboratory. To create the prototype for the ISS, we needed to shrink the printer to the dimensions of a washer. At this measurement, we are able to print elements with a quantity of 9 centimetres excessive and 5 centimetres large.”

The second problem is security, defending the ISS from the aggressive printing setting attributable to the laser and the warmth that it generates. The printer sits in a sealed metallic field, which acts like a protected. Airbus says the melting level of metallic alloys suitable with this course of may be far over 1,200°C in comparison with round 200°C for plastic.

“Gravity administration can be key, which is why we selected wire-based printing expertise. The wire is impartial of gravity not like the powder-based system, which at all times has to fall to the bottom,” added Girault.

Fumes which are emitted should be handled by filters and captured contained in the machine so they don’t contaminate the air contained in the ISS. Aridon stated: “Security and contamination are key drivers for us not just for the ISS, however for future use on the Moon.”

AddUp’s Technical Director, Sébastian Devroe added: “The event of the Metallic 3D printer depends on the distinctive multidisciplinary experience of AddUp’s engineers and researchers. Our workers has experience throughout quite a lot of additive manufacturing processes, machine design, programming, and operation optimisation. Our groups have supported the event of this primary metallic 3D printer, which can quickly be in orbit. The metallic 3D printer has been designed and optimised to satisfy the circumstances and setting of the Worldwide Area Station.”

Two 3D printers might be used for this experiment, to check if metallic 3D printing is suited to a microgravity setting. The “flight mannequin” might be contained in the ISS, and the “engineering mannequin” might be on Earth. The astronauts will 3D print 4 samples in area, which might be despatched again to Earth for evaluation. The identical specimens might be manufactured utilizing the engineering mannequin printer.

Girault stated: “In an effort to consider the consequences of microgravity, ESA and Danish Technical College will carry out mechanical energy and bending checks and microstructural evaluation on the elements made in area and evaluate them to the opposite specimens.”

Airbus says that metallic 3D printing onboard the ISS will assist to enhance the understanding of the standard of metallic printing in orbit and supply helpful insights into working a metallic 3D printer in area. The corporate says that 3D printing structural elements in area is a vital step in making ready the applied sciences humankind will want for a sustained presence on the moon.

“Growing the extent of maturity and automation of additive manufacturing in area may very well be a recreation changer for supporting life past Earth,” added Aridon. “Pondering past the ISS, the functions may very well be wonderful. Think about a metallic printer utilizing reworked regolith [moondust] or recycled supplies to construct a lunar base!”

Head of Engineering at Airbus Area Techniques Elodie Viau stated: “AddUp was chosen for this undertaking based mostly on an extended historical past and partnership rooted in exploration and innovation. We’re assured that with the data and expertise the AddUp crew has, mixed with the technological experience of Airbus, collectively we’d achieve success in delivering a top quality and environment friendly metallic 3D printer to assist the exploration of area.”

Extra tales involving Airbus: