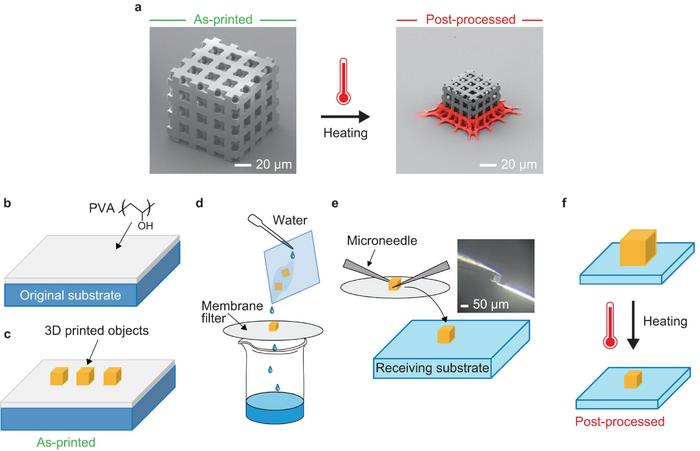

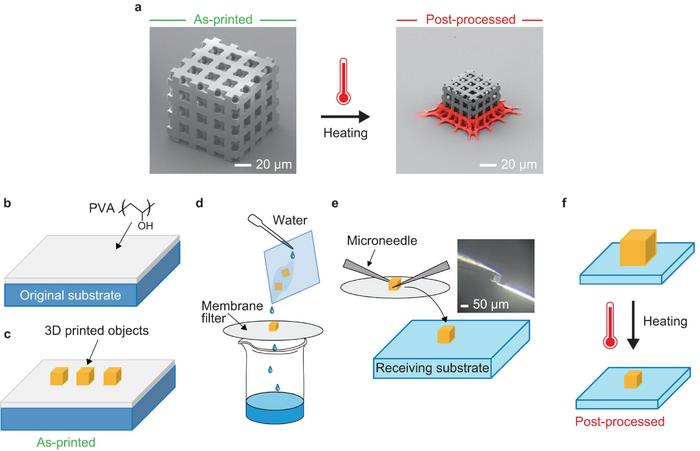

Researchers have developed a brand new methodology to make sure uniform shrinkage in 3D printed micro and nanostructures, utilizing two-photon polymerization lithography (TPL). The crew, led by Professor Joel Yang from the Singapore College of Expertise and Design (SUTD), collaborated with the Industrial Expertise Heart of Wakayama Prefecture in Japan. Their course of employs a layer of poly(vinyl alcohol) (PVA) on the printing substrate, enabling the switch of 3D printed components onto a separate substrate for managed discount. This method addresses the problem of non-uniform shrinkage and expands the potential functions of TPL.

The analysis, revealed in Nature Communications, showcases the profitable software of this methodology on complicated geometries. The unfastened attachment of the constructions to the brand new substrate permits for uniform shrinkage throughout heating, avoiding distortions. This method not solely overcomes limitations in decision and materials rigidity but in addition permits for the combination of microscopic 3D printed components with different gadgets or substrates unsuitable for TPL.

This method opens up new potentialities, corresponding to creating supplies that change colours in response to lighting circumstances, helpful in anti-counterfeiting. It additionally guarantees developments in manufacturing intricate warmth sinks for high-performance electronics and permits the creation of mechanical components, optical parts, and acoustic gadgets with excessive precision.

The crew plans to increase the applying of their method to supplies with increased refractive indices for improved photonic crystals, enhancing applied sciences in lasers, imaging programs, and optical sensors. They’re additionally refining the management of spacing in printed constructions for full-color, 3D fashions that manipulate mild exactly.

You may learn the analysis paper titled “Decide and place course of for uniform shrinking of 3D printed micro- and nano-architected supplies” over at this hyperlink.

Come and tell us your ideas on our Fb, X, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.