As he extols the virtues of the expertise facilitating a satellite tv for pc weighing lower than 100kg, Tony Boschi exhibits the depth of his expertise with the repeated use of two phrases: speedy prototyping.

Boschi has been working with 3D printing expertise for thus lengthy, that he not solely refers back to the processes utilizing that phrase, however he additionally has the warfare tales. When he first used the expertise, for instance, he and his colleagues took to squirting hairspray on stereolithography (SLA) components to forestall the sticky texture they had been left with when popping out of the printer, and in flip permitting any paint utilized to the elements to dry sooner.

“It was one of many best issues on this planet,” he recollects considering. However such glee is relative. Lately, as Lead Design Checker at Sidus Area, he has printed pattern holder components in Markforged’s Onyx carbon fiber-filled nylon materials that fashioned a part of a flight take a look at platform put in on the surface of the Worldwide Area Station (ISS) for a 12 months. That the components survived on the ISS with subsequent to no degradation emboldened Sidus Area to push ahead with the concept of manufacturing the construction of its LizzieSat satellites with 3D printing.

Sidus Area was based by Carol Craig, a former US Navy officer who grew to become the primary lady eligible to fly fight plane within the US Navy, to hold buyer sensors and accumulate information for a large number of various clients on the similar time.

The partially printed LizzieSat constellation will launch for the primary time later this 12 months on the SpaceX Transporter-9, if it weighs much less 100kg.

This has represented a major problem for Boschi and the Sidus staff, particularly since integral componentry like batteries and computer systems take up a good portion of the satellite tv for pc’s total weight. However it’s one they backed themselves to beat with the mix of their engineering prowess and 3D printing expertise.

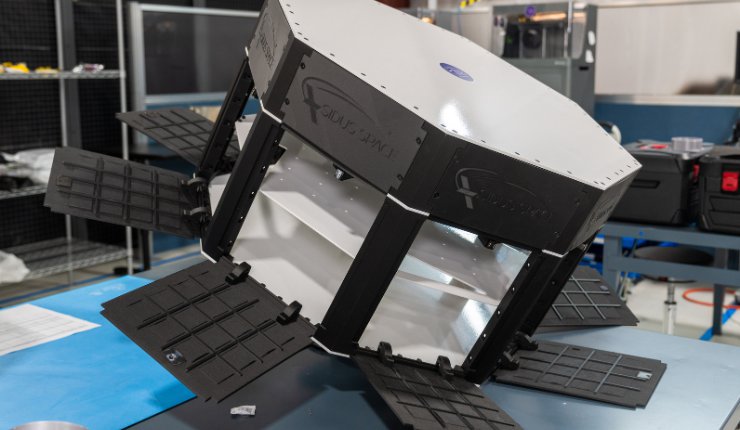

Within the design of the LizzieSat, they’ve utilized Markforged’s composite 3D printing expertise to your complete construction of the 31 x 31 x 18 inch satellite tv for pc, harnessing the corporate’s Onyx FR and Onyx FR-A supplies on eight vertical and eight horizontal elements that maintain in place a honeycomb construction. With this use of carbon-fibre crammed nylon, Sidus says it is ready to leverage related power qualities to aluminium, whereas decreasing the load and iterating on designs way more rapidly.

Throughout design iteration, Boschi included fastening performance into the structural elements in order that components match right into a slot and lock into place. This has not solely helped to shave off weight by eradicating screws and bolts however has additionally made the satellite tv for pc sturdier.

“Once we began doing the preliminary evaluation, you possibly can see that when the components had been bolted collectively, they had been all separate,” Boschi says. “However after we made the locking function, then your complete ring grew to become one piece, in order that we’re solely pulling on one construction, versus 16 items –as a result of there are eight columns and eight items in between to carry them collectively. Now we put every part collectively, all of them get bolted to the honeycomb or the aluminium pan on the opposite aspect, it’s extra of a stronger, stout construction.”

On the time of writing, Sidus is in ‘full print’ mode forward of the potential SpaceX launch later this 12 months. The design has been locked in, the honeycomb and base plate are due for arrival in April, after which the satellite tv for pc will undergo an in depth testing course of to show out its sturdiness. The LizzieSat satellite tv for pc has been constructed for a five-year life, whereas Sidus has needed to understand that as it’s launched into outer area, it must take 5G hundreds, face up to photo voltaic radiation, and take care of huge temperature swings of round 200°C because it goes from the publicity of direct daylight to the shade of the Earth’s shadow.

For Boschi, he’s by no means been extra positive that 3D printed components can handle it. “Once I first did components years in the past with SLA machines, we’d break them taking them out of the machine. When you didn’t put it down proper, it could break. And it’s superior from that time ahead. Now we’re in nylon. Higher supplies, it’s altering every part. From that time once I was first [using 3D printing], it’s night time and day.”