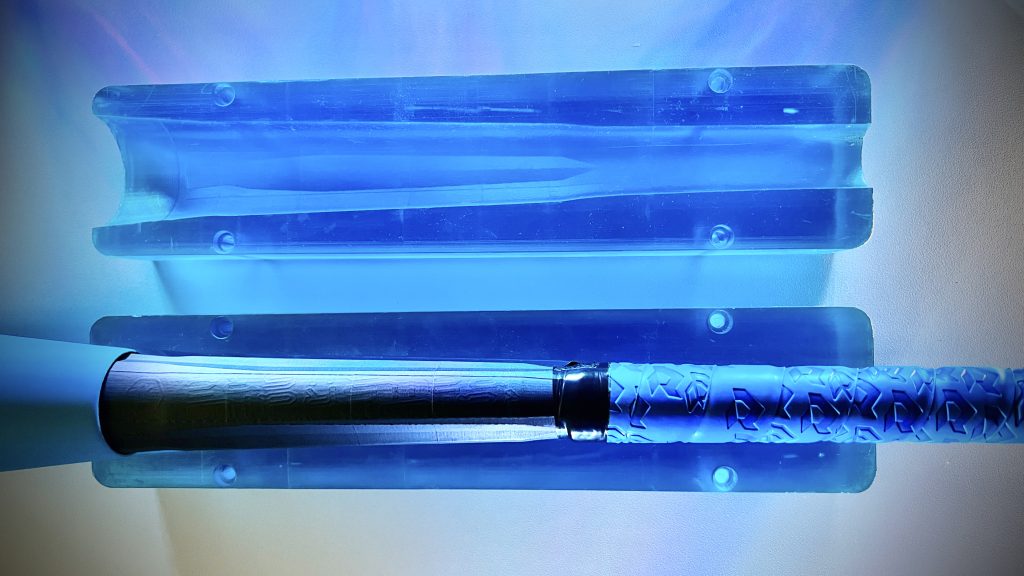

Japanese way of life golf model Designer has launched its new titanium 3D printed golf membership heads.

Manufactured utilizing metallic 3D printers from Farsoon Applied sciences, the golf membership heads are marketed as being ultra-strong and light-weight. Designer’s latest product additionally encompasses a novel head-design, with self-supported inside buildings.

In response to Farsoon, the corporate’s 3D printing know-how enabled the golf model to innovate, design, and produce “top-of-the-line membership heads” for gamers looking for to realize better distance, accuracy, and stability.

The Designer membership heads add to Farsoon’s rising record of collaborations to 3D print sport gear. The corporate’s 3D printers have beforehand been used to fabricate bobsled helmets, velocity skating blades, and sports activities sneakers.

The 3D printed golf membership heads are presently being showcased on the PGA Present in Orlando, which can run till January 26.

New 3D printed golf membership heads

Designer’s new golf membership heads are manufactured in sequence manufacturing runs utilizing Farsoon Applied sciences’ FS200M laser powder mattress fusion (LPBF) 3D printer.

In response to Farsoon, Designer’s FS200M 3D printer has enabled the corporate to cut back price per half by 70% from design to manufacturing, in comparison with typical manufacturing processes. Moreover, Farsoon’s metallic 3D printer permits multi-layer thickness parameters to be custom-made, boosting productiveness.

The golf membership heads are 3D printed from a custom-made, “ultra-strong” titanium alloy. Farsoon claims that this materials encompasses a mixture of light-weight and energy that’s superior to standard chrome steel merchandise. Furthermore, Designer’s new providing is alleged to supply a high-speed influence floor with enhanced ductility and energy for optimum strikes of the golf ball.

Along with quicker design and verification iterations, Farsoon 3D printing is alleged to allow extra progressive designs not doable with typical manufacturing strategies. This consists of the golf membership head’s self-supported inside buildings, which contribute to thinner, stronger, and textured exterior surfaces.

The toe, face, sole, crown, heel and hosel geometries of the golf membership heads are 3D printed as one piece. This reportedly allows improved precision and efficiency over typical strategies, and affords better resistance to twisting, elevated stability, and superior driving distance.

Farsoon Applied sciences additionally factors to the 3D printed membership head’s built-in aerodynamic options, which scale back drag over the built-in geometries. That is stated to extend head stability and velocity.

Farsoon Applied sciences’ rising sport portfolio

Designer’s new golf merchandise will not be the primary to be produced utilizing Farsoon 3D printers. Futai Know-how beforehand leveraged seven Farsoon metallic 3D printers, together with the FS200M and FS273M, to scale-up the sequence manufacturing of its titanium golf membership heads.

In response to Futai, the corporate delivers greater than 15,000 titanium 3D printed golf membership heads to clients every year, with 3D printer uptime exceeding 90%. Furthermore, Farsoon 3D promoters have reportedly diminished product improvement time from 45 days to only one week, saving 70% in bills within the course of.

Away from golf, in 2021 Farsoon signed a collaborative settlement with the Chinese language Olympic Committee to develop a brand new era of 3D printed velocity skating blades. Manufactured on the corporate’s FS421M 3D printer, these blades are comprised of AlMgSc alloy and are light-weight, robust, and customised for high-performance skating.

Farsoon 3D printers have additionally been used to develop 3D printed TPU helmets for China’s 2022 Winter Olympic bobsled workforce, in addition to 3D printed sports activities sneakers for Chinese language sportswear producer Peak Sport Merchandise.

3D printing: the way forward for sports activities gear manufacturing?

In an interview with 3D Printing Business, Glen Mason, Director of Superior Manufacturing at sports activities gear producer Wilson, outlined the challenges in transferring from prototyping to producing sports activities items with additive manufacturing.

“There’s challenges round printing elements from a cloth standpoint, from a floor end standpoint, and even one thing as trivial as shade is difficult,” defined Mason. “Till we will get a number of supplies interacting on the similar time, I don’t foresee 3D printing fixing any client initiatives.”

Nevertheless, whereas not mass 3D printing finish elements, Wilson has integrated additive manufacturing into its manufacturing workflow. Final 12 months, the US-based firm introduced a partnership with Nexa3D to leverage its high-speed NXE400 resin 3D printers.

Wilson used Addifab’s freeform injection molding (FIM) know-how and xMOLD soluble resin, to prototype 3D printed injection mould tooling for Wilson’s youth baseball bat grips. This course of supplied improved design prospects, time-savings, and R&D freedom.

Elsewhere, it was introduced final 12 months that multinational printing agency HP had partnered with Brooks Operating to 3D print midsoles for the corporate’s limited-edition Exhilarate-BL trainers. Produced utilizing HP’s Multi Jet Fusion (MJF) 3D printing know-how, the 3D printed working shoe midsoles are stated to offer a propulsive and springy really feel, outperforming 90% of midsoles in the marketplace.

Brooks’ 3D printed providing was made accessible in a restricted launch to pick out put on testers and Run Membership members with synced wearables by Brooks’ platform in alliance with DashLX. This launch was used to help the corporate’s shoe designs by amassing working knowledge akin to stride lengths and cadences.

Equally, sports activities gear manufacturing agency Adidas launched a limited-edition 3D printed golf shoe, the MC87 4D. Produced utilizing Carbon’s Digital Gentle Synthesis (DLS) 3D printing course of. This golf shoe incorporates a singular “4D midsole” lattice construction, designed to offer managed power return.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture reveals Designer’s 3D printed golf membership heads. Picture by way of Farsoon Applied sciences.