Massachusetts Institute of Expertise (MIT) researchers have developed 3D printed self-heating microfluidic units, providing potential purposes in inexpensive illness detection instruments.

MIT’s analysis group adopted multimaterial 3D printing, an economical technique, to create self-heating microfluidic units in a single manufacturing step. This method permits for personalisation, enabling engineers to design microfluidic units with particular heating profiles or temperatures in designated areas. Requiring roughly $2 value of supplies, the low-cost fabrication course of holds potential to be used in distant areas of creating nations the place entry to costly lab tools is restricted.

“Clear rooms specifically, the place you’ll often make these units, are extremely costly to construct and to run. However we will make very succesful self-heating microfluidic units utilizing additive manufacturing, and they are often made rather a lot sooner and cheaper than with these conventional strategies. That is actually a approach to democratize this know-how,” says Luis Fernando Velásquez-García, a Principal Scientist in MIT’s Microsystems Expertise Laboratories (MTL) and senior creator of a paper describing the fabrication method.

Self-heating microfluidic units

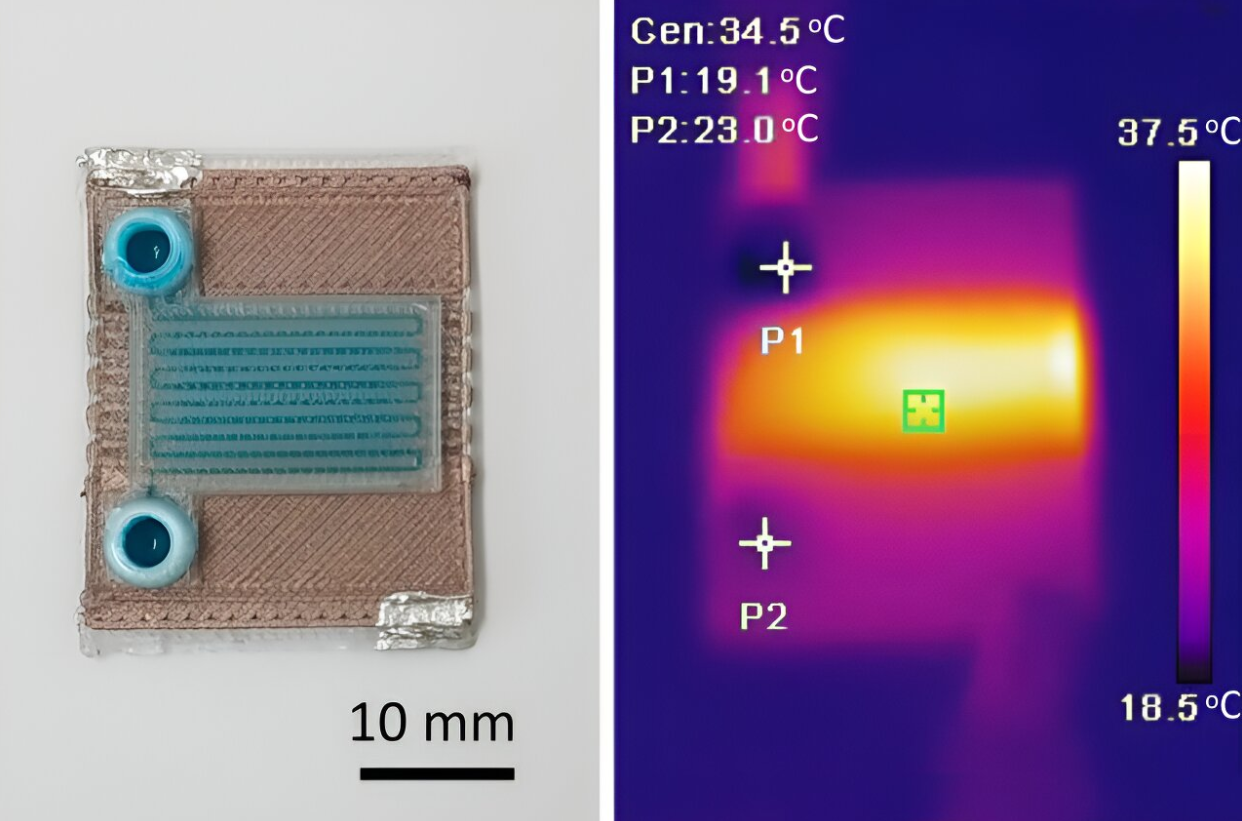

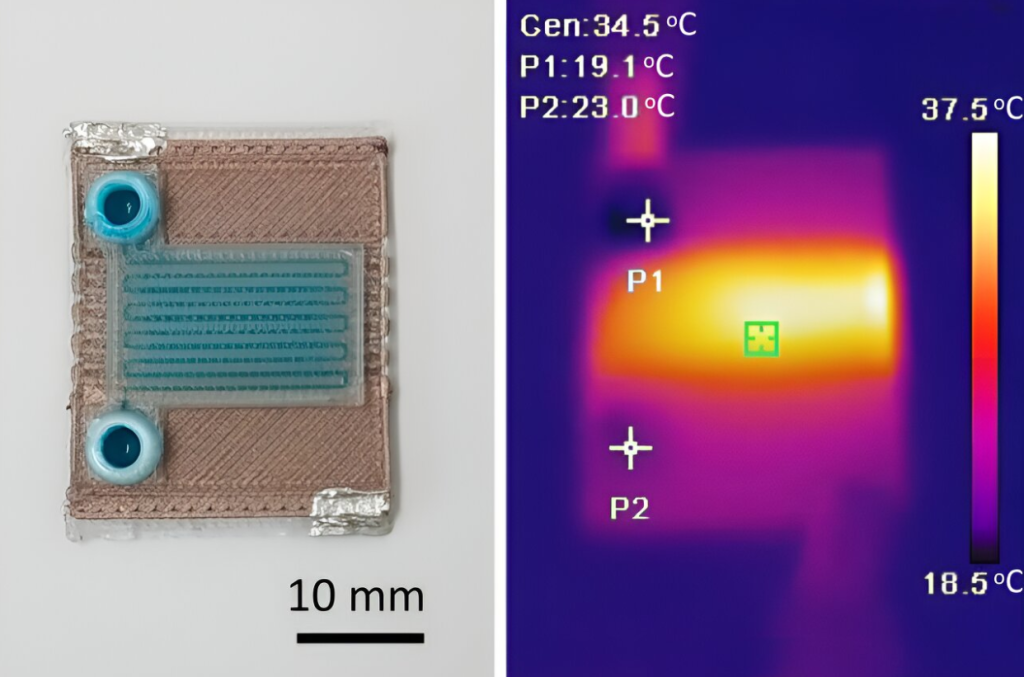

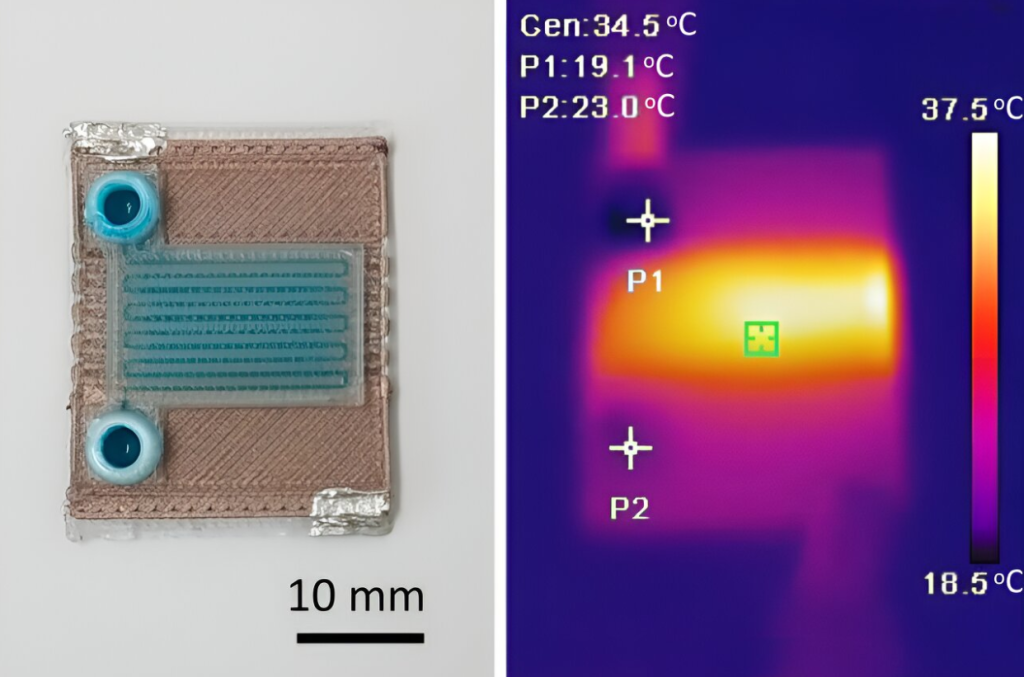

The researchers utilized multi-material extrusion 3D printing, incorporating a biodegradable polymer (polylactic acid or PLA) and a modified model infused with copper nanoparticles. When remodeled right into a resistor, this modified PLA turns into conductive, permitting the dissipation {of electrical} present as warmth. The result’s a self-heating microfluidic system produced in a single step on a 3D printer.

“It’s wonderful when you consider it as a result of the PLA materials is a dielectric, however whenever you put in these nanoparticle impurities, it utterly adjustments the bodily properties. That is one thing we don’t absolutely perceive but, however it occurs and it’s repeatable,” added Velásquez-García.

To handle challenges associated to warmth switch and fluid leakage, the researchers added a skinny, steady layer of PLA between the resistor and microfluidic channels. Roughly the dimensions of a U.S. quarter, the ensuing system options channels 500 mm extensive and 400 mm tall facilitating fluid circulate and chemical reactions. Moreover, the group utilized a one-step manufacturing course of to create a prototype able to heating fluid by 4°C because it flowed between the enter and the output. This customizable method opens potentialities for creating units that warmth fluids in particular patterns or alongside designated gradients, showcasing the know-how’s adaptability in numerous purposes.

Regardless of the success of the prototype, limitations exist, such because the PLA’s most temperature of round 50°C, hindering purposes requiring greater temperatures. The group goals to combine a 3rd materials for temperature sensing and discover using printed magnets for particle sorting or alignment. Whereas the simplicity of the proposed 3D printed microfluidic techniques has garnered consideration, additional analysis is required to deal with present limitations and refine the capabilities of this know-how for sensible purposes.

Medical 3D printing analysis from MIT has beforehand made headlines. Final 12 months in March, MIT researchers developed a technique for 3D printing gentle replicas of sufferers’ hearts to imitate their distinctive blood-pumping capabilities. Remodeling medical photos into 3D laptop fashions, the group makes use of polymer-based ink to print exact, versatile constructions of sufferers’ hearts.

Sleeves across the 3D printed hearts and aortas simulated pumping actions, permitting researchers to tune the outflowing air for rhythmic pumping. Leveraging scans from 15 sufferers with aortic stenosis, the strategy concerned changing their medical scans into 3D laptop fashions, showcasing its potential for creating customized coronary heart fashions for therapy analysis.

Microfluidics enhancing point-of-care

The mixing of 3D printed microfluidics in point-of-care settings has the potential to remodel diagnostics. With fast prototyping and low-cost manufacturing, 3D printing permits tailor-made units to deal with particular diagnostic wants. As 3D printing advances, it holds promise in enhancing accessible point-of-care diagnostics.

Up to now, College of Bristol researchers launched an inexpensive and open-source 3D printing technique for creating microfluidic units, particularly utilizing PolyDimethylSiloxane (PDMS). Leveraging normal home tools and a desktop 3D printer, it lowers prices and boosts accessibility in microfluidics analysis. The method holds potential for inexpensive point-of-care diagnostic know-how, impacting fields equivalent to laboratories-on-a-chip, cell biology, and protein crystallization.

Elsewhere, Stevens Institute of Expertise researchers employed computational modeling to advance microfluidics-based 3D bioprinting, aiming for the fabrication of complete human organs. Not like extrusion-based bioprinters, their microfluidics method exactly manipulates liquids by tiny channels, enabling constructions as small as tens of microns.

On this case, cellular-scale precision was essential for mimicking organic options precisely. The group sees microfluidics as a key consider overcoming the technological limitations of present 3D bioprinting, doubtlessly revolutionizing organ transplants by engineering advanced tissues and even pores and skin instantly onto wounds.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will should be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

Featured picture reveals MIT researchers developed a fabrication course of to supply self-heating microfluidic units in a single step utilizing a multi-material 3D printer. Pictured is an instance of one of many units. Picture by way of Massachusetts Institute of Expertise.