MIT researchers have used 3D printing to develop self-heating microfluidic gadgets, demonstrating a method which the workforce says may someday be used to quickly create low-cost, however correct, instruments to detect varied illnesses.

Microfluidics, miniaturised machines which manipulate fluids and facilitate chemical reactions, can be utilized to detect illness in small samples of blood or fluids. At-home Covid-19 take a look at kits for instance include a easy sort of microfluidic.

The MIT workforce says that many microfluidic functions require chemical reactions that have to be carried out at particular temperatures. These extra advanced gadgets are outfitted with heating parts constituted of gold or platinum utilizing an costly fabrication course of.

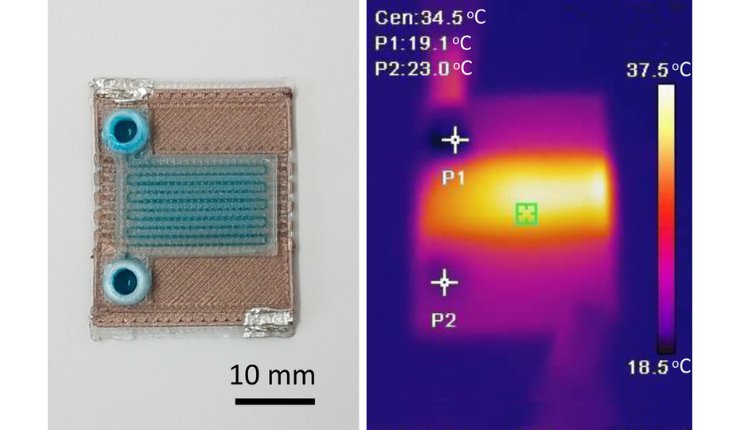

The workforce of MIT researchers used multi-material 3D printing to create self-heating microfluidic gadgets with built-in heating parts, by a single course of which the workforce says was cheap. The workforce generated gadgets that may warmth fluid to a particular temperature because it flows by microscopic channels contained in the machine.

The method is customisable in accordance with the workforce, so an engineer may create a microfluidic machine that heats fluid to a sure temperature or given heating profile inside a particular space of the machine. The workforce says the method requires round 2 USD of supplies to generate a ready-to-use microfluidic.

The researchers say the method might be particularly helpful in creating self-heating microfluidics for distant areas of creating nations the place clinicians won’t have entry to the costly lab gear required for sure diagnostic procedures.

“Clear rooms specifically, the place you’ll normally make these gadgets, are extremely costly to construct and to run. However we are able to make very succesful self-heating microfluidic gadgets utilizing additive manufacturing, and they are often made loads sooner and cheaper than with these conventional strategies. That is actually a method to democratise this know-how,” stated Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Expertise Laboratories (MTL) and senior creator of a paper describing this new method.

Velásquez-García spoke to TCT in April 2023 about an MIT venture by which researchers created fully 3D printed sensors for satellites. He’s joined on the paper for this new course of by lead creator Jorge Cañada Pérez-Sala, {an electrical} engineering and laptop science graduate pupil.

The brand new course of utilises multi-material extrusion 3D printing, by which a number of supplies will be dispersed by the printer’s nozzles to construct a tool. The method is monolithic, which suggests the machine will be produced in a single step on the 3D printer, with out the necessity for post-assembly.

The researchers used two supplies to create the gadgets, polylactic acid (PLA) and a modified model of PLA which was cooper nanoparticles combined into the polymer, which converts the fabric into {an electrical} conductor.

“It’s wonderful when you consider it as a result of the PLA materials is dielectric, however if you put in these nanoparticle impurities, it fully modifications the bodily properties. That is one thing we don’t absolutely perceive but, however it occurs and it’s repeatable,” stated Velásquez-García.

The researchers used this one-step manufacturing course of to generate a prototype that would warmth fluid by 4 levels Celsius because it flowed between the enter and the output. This system may allow the workforce to make gadgets which might warmth fluids in sure patterns or alongside particular gradients.

Velásquez-García added: “You need to use these two supplies to create chemical reactors that do precisely what you need. We will arrange a specific heating profile whereas nonetheless having all of the capabilities of the microfluidic.”

A limitation that comes with this course of is that PLA begins to degrade as soon as it reaches round 50 levels Celsius. The workforce says that many chemical reactions, reminiscent of these used for polymerase chain response (PCR) exams, require temperatures of 90 levels or increased. To exactly management the temperature of the machine, the researchers say they would wish to combine a 3rd materials that permits temperature sensing.

In addition to tackling these limitations in future work, Velásquez-García says he desires to print magnets immediately into the microfluidic machine. The workforce says these magnets may allow chemical reactions that require particles to be sorted or aligned.