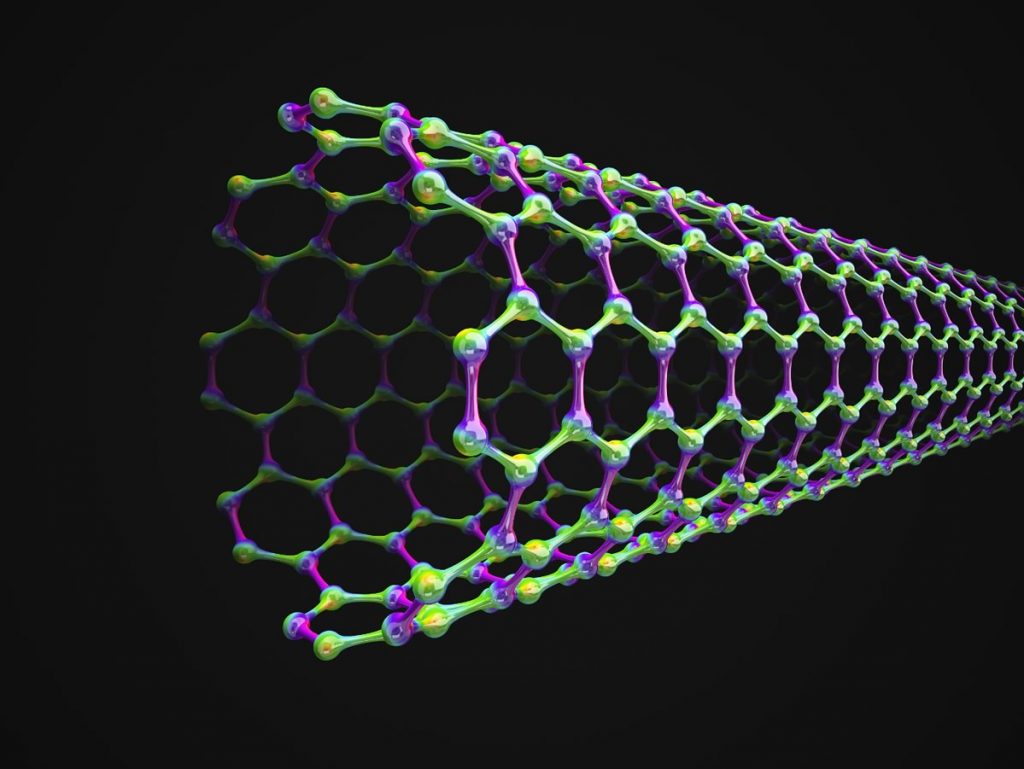

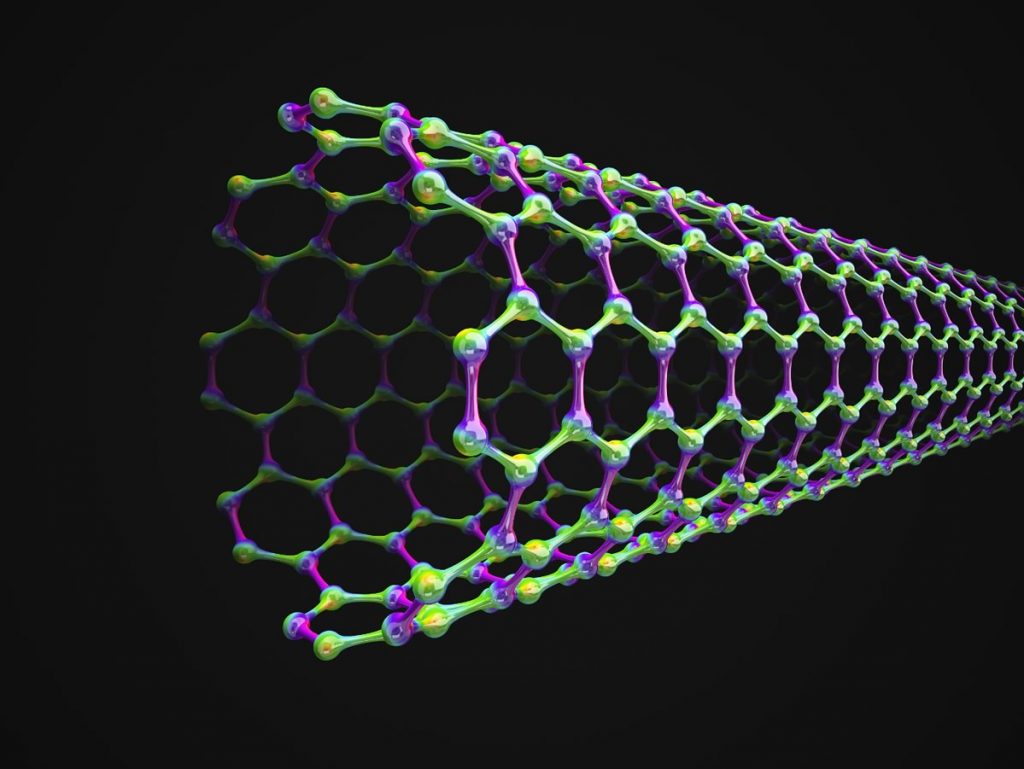

Following the E35B+ materials launch, Mechnano and Bomar have launched a brand new materials dubbed T50B masterbatch, designed particularly for the additive manufacturing (AM) business.

Using Mechnano’s unique D’Func expertise, the just lately launched product concentrates on Discrete, Dispersed, and Functionalized Carbon Nanotubes. Its key aim is the enhancement of mechanical properties and the upkeep of constant electrical efficiency on the nanoscale inside AM resins. Distinguished by its elevated focus of Carbon Nanotubes (CNT) and minimal viscosity, the T50B masterbatch facilitates easy incorporation into resin formulations, eliminating the need for extended shear mixing procedures.

“Mechnano Analysis and Growth groups proceed to boost our applied sciences and increase our product portfolio for the AM business,” says Mechnano Director of Purposes & Know-how, Dr. Olga “Dr.O” Ivanova. “The preliminary suggestions from beta-customers has been extraordinarily constructive, demonstrating enhanced mechanical efficiency, along with ESD capabilities.”

T50B resin’s multifaceted capabilities

Identified for its versatility, the T50B demonstrates compatibility throughout an in depth array of resin varieties and applied sciences. Its distinctive formulation incorporates Bomar resins because the dispersion base, facilitating the event of sturdy, pliable, and supple AM resins. These resins, tailor-made for numerous printing methodologies corresponding to Stereolithography (SLA), Digital Mild Processing (DLP), or jetting, underscore the adaptability of the T50B, owing to its proprietary mix and capability to fulfill the necessities of various additive manufacturing processes.

Extending its adaptability, the T50B permits for the fine-tuning of its electrical resistivity throughout the vary of 105-1010 Ω, catering to purposes demanding exact electrical properties. Furthermore, the mixing of T50B into resilient and pliable formulations has yielded notable developments in mechanical traits, manifesting as enhancements in each tensile energy and modulus. These findings point out promising benefits for manufacturing parts with total enhanced efficiency, showcasing the potential influence of incorporating T50B in numerous purposes, says the corporate.

“This new dispersion is precisely what the business has been in search of – a flexible, extremely concentrated dispersion that allows most formulation flexibility and offers glorious ESD properties, all whereas sustaining printability in UV-based print programs,” says David Robitaille, World Model Director for Bomar.

As a part of its ongoing efforts to increase its product vary, Mechnano is providing the T50B masterbatch straight, and it is usually obtainable by its companion, Bomar.

3D printing resin developments

Netherlands-based 3D printing resin producer Liqcreate added the Liqcreate Flame Retardant HDT resin to its portfolio, catering to engineering, mobility, shopper items, and electronics purposes. This off-white photopolymer resin gives high-temperature resistance, boasting a UL94 V0 flammability score. Suitable with numerous 3D printing programs, it withstands temperatures as much as 257°C (495°F), making it appropriate for automotive, aerospace, and digital parts. Thorough testing, together with UL94 and FAR 25.853 evaluations, ensures compliance with security requirements, paving the way in which for purposes in aviation and mobility sectors.

Queensland College of Know-how researchers performed a case examine evaluating 3D printing resins for microfluidic parts in cell-based purposes. Utilizing MOIIN Excessive Temp and MOIIN Tech Clear resins from DMG Digital Enterprises with ASIGA UV Max X27 DLP 3D printers, they printed frequent microfluidic designs. The examine, led by Louis Ong and Yi-Chin Toh, demonstrated MOIIN resins’ feasibility for advanced 3D printing, cell trapping, and compatibility with imaging platforms. The resins proved biocompatible and appropriate for microscopy imaging, showcasing potential purposes in speedy prototyping for biomedical functions.

Learn all of the 3D Printing Trade protection from Formnext 2023.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

Featured picture reveals Mechnano’s T50B resin. Photograph by way of Mechnano.