This yr noticed notable breakthroughs within the medical sector, together with a brand new utility in 3D printing for hair follicle analysis by researchers at US-based Rensselaer Polytechnic Institute (RPI).

3D Printing Trade interviewed Pankaj Karande, Affiliate Professor, Chemical and Organic Engineering at RPI to be taught extra about this novel research.

The analysis, additionally involving lead creator Carolina Catarino, and collaborative associate Grupo Boticario explores the potential for in vitro research to advance molecules selling hair progress and enhancing transplantation success. This revolutionary strategy holds promise for expediting advanced pores and skin graft growth, notably benefiting regenerative drugs functions equivalent to burn sufferer remedy.

“It’s tempting to suppose that now we have now been in a position to develop an answer for hair restoration. Translation of our proof-of-concept research to demonstrating that we are able to kind fully-grown hair in human pores and skin would require extra analysis and optimization. To not point out regulatory concerns in translating this analysis to human sufferers. Our research have made vital contributions however there may be nonetheless a variety of work forward,” says Professor Karande.

Bioprinting of purposeful hair follicles in pores and skin constructs

Professor Karande explains that to provide the bioprinted pores and skin pattern, the preliminary step includes designing bioinks composed of biomaterials equivalent to proteins and cells. Continuing with affected person consent, the staff sourced these cells from discarded pores and skin samples both isolating them in-house or buying them commercially. The isolation course of takes roughly two weeks, after which the cells bear a cultivation and growth part within the laboratory lasting 1 to 4 weeks to extend their numbers. Subsequently, the cells are mixed with proteins and different biomaterials to formulate the bioinks.

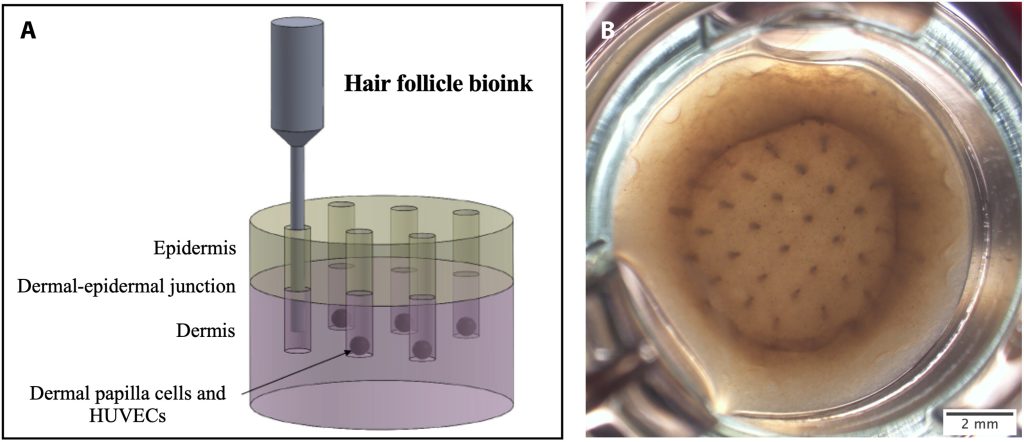

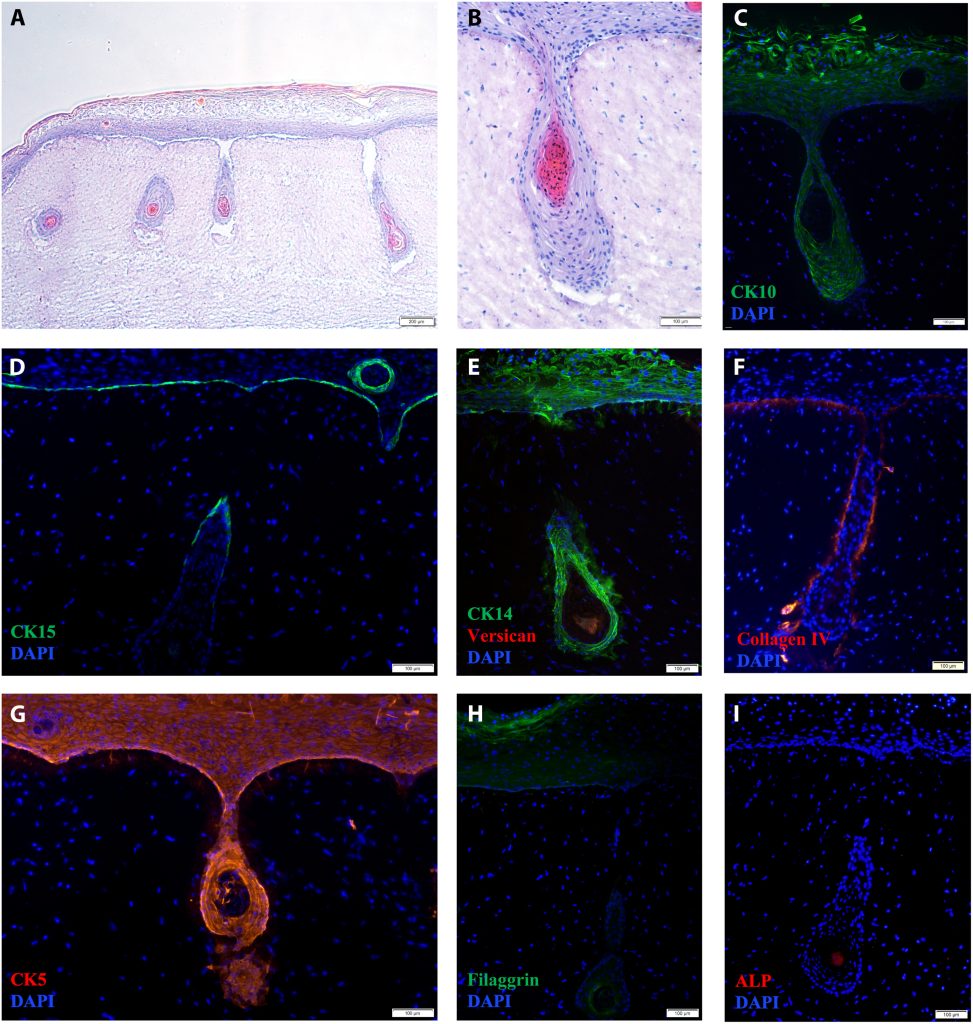

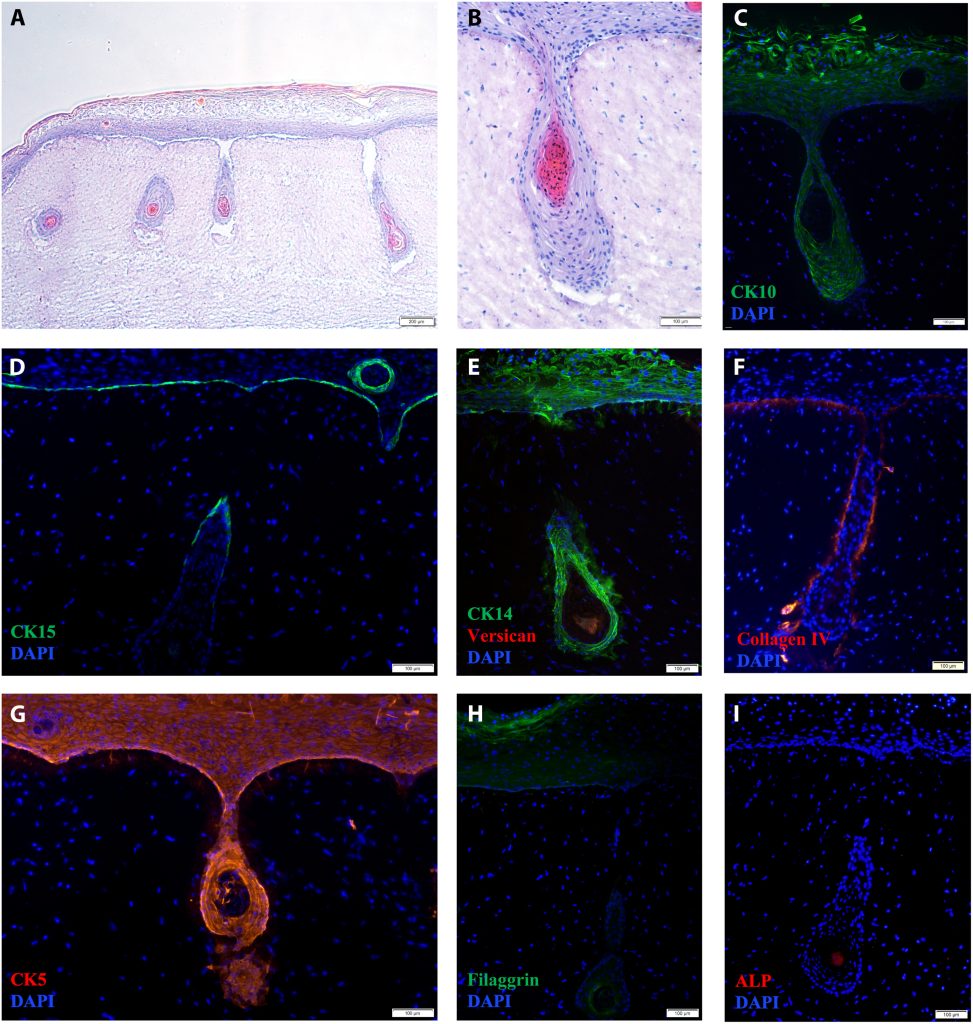

The bioinks are then loaded into the bioprinting gear which may be very comparable in idea to the standard 3D printers. As an alternative of utilizing inks product of melted plastic, polymers, or resins, the staff makes use of cartridges full of organic materials. As soon as loaded, a pre-programmed algorithm guides the deposition of every materials, making a 3D tissue. “The method begins with the deposition of the bottommost layer (dermis), primarily composed of collagen I and dermal cells. After the dermis gels, the printing progresses to incorporate hair follicles and the exterior pores and skin layer (dermis). This complete printing course of for 12 samples (every about an inch in diameter) usually takes round 1 hour,” he mentioned.

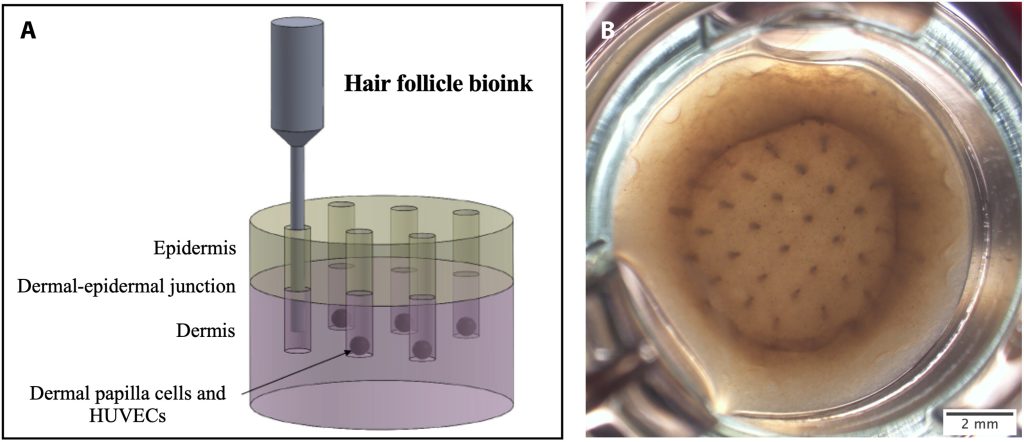

Following printing, the samples bear incubation in a managed setting with common media modifications, sustaining optimum temperature and CO2 ranges. This roughly 2-week incubation interval permits the tissue to mature to its last stage. Subsequently, the bioprinted pores and skin samples bear in vitro substance evaluations, signifying a serious development in numerous tissue engineering strategies.

Revolutionizing hair follicle regeneration

He additional defined that reconstructing hair follicles utilizing human-derived cells is difficult because of the lack of stem-cell-like traits exterior their pure setting. Cells wrestle to generate new follicles with out this context. Analysis means that culturing them in a three-dimensional setting partially restores their capability, doubtlessly forming new follicles or shafts. To deal with this problem, the staff’s distinctive strategy makes use of bioprinting expertise to recreate the three-dimensional setting, facilitating the restoration of cell inductive capability in pores and skin mannequin reconstruction with hair follicles, in response to the Professor.

From a technical standpoint, the primary problem in realizing the undertaking concerned integrating numerous cell sorts into designated bioinks and aligning {hardware} and software program to construct purposeful human tissue. Coordinating these components posed a major technical hurdle for the staff, highlighting the complexity of advancing hair follicle regeneration.

“Once we discuss in vitro fashions for efficacy and toxicity testing of compounds, we don’t anticipate any aspect impact of getting hair follicle. The inclusion of such construction may improve our predictivity capability to grasp the impact of a compound because the mannequin could be extra physiologically related and permit us to check different organic course of equivalent to hair progress,” he says. Relating to the potential use of those fashions for regenerative drugs, there may be all the time the inherent danger of rejection by the physique equivalent to in any transplant. Sooner or later, the staff plans to doubtlessly mix the expertise used to provide the fashions with the usage of patient-derived cells utilizing iPSCs cells which may cut back the possibility of rejection.

Navigating bioprinting: customization and organic realities

Numerous bioprinting applied sciences, together with extrusion, inkjet, laser-assisted, and stereolithography, have been explored by researchers. Every expertise calls for customization in printing protocol, bioink composition, cross-linking mechanism, and curing. The mixture of bioinks, bioprinter, and printing program enabled the staff to design a 3D mannequin inside related limitations, says the Professor.

“Nonetheless, though such expertise permits us to extend the complexity of what’s being created within the laboratory we nonetheless depend on biology to do a lot of the work. We will outline the hair density we want to print and even direct the expansion route; nonetheless, hair colour and fiber curvature are largely outlined by the DNA inside the cells,” defined Professor Karande.

He additional defined that presently, the fashions developed are produced in a laboratory below managed situations of temperature, humidity, and with out direct daylight publicity. Transferring ahead within the growth of those fashions, environmental components equivalent to daylight publicity in addition to completely different humidity situations and utility of gear will probably be evaluated to check the robustness of the mannequin.

Optimizing pores and skin mannequin complexity for future functions

The introduced work is a proof of idea, demonstrating the effectivity of 3D bioprinting in enhancing the complexity of reconstructed pores and skin fashions. Whereas not but prepared for commercialization, the staff is actively refining the printing protocol and enhancing media composition for an prolonged tradition interval. Present bioprinters can produce a number of tissues or mini organoids of hair follicles inside an hour, and as expertise evolves, throughput is anticipated to extend. The main focus stays on advancing the approach and optimizing scalability for future functions.

The Professor defined that the staff’s goal is to optimize situations for sustained progress and maturation. They categorical curiosity in assessing the viability of the engineered tissue, notably the hair follicles, to develop hair shafts when grafted onto an animal mannequin. The subsequent step includes transitioning to scientific exams earlier than the expertise could be dropped at the market.

“We’re thinking about exploring the potential of our mannequin for in vitro testing of various topical compounds and their efficiency or toxicity for varied medical and beauty functions. For this case, as soon as these optimizations and in vitro validations have been carried out, the mannequin may very well be commercialized. Keep tuned for forthcoming updates as we intention to share our progress and findings by way of publications within the close to future,” concluded Professor Karande.

Learn all of the 3D Printing Trade protection from Formnext 2023.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

Featured picture reveals from left to proper: Pankaj Karande and Carolina Catarino. Picture by way of RPI.