Following the America Makes venture name winners announcement, Elementum 3D has introduced that America Makes has chosen its proposal for the high-strength A7050-RAM2 aluminum additive manufacturing (AM) feedstock qualification.

Funded by the Workplace of the Beneath Secretary of Protection, Analysis and Engineering Manufacturing Know-how Workplace (OSD(R&E)) and the Air Pressure Analysis Laboratory (AFRL), this venture has awarded Elementum 3D with value reimbursements as much as $2,875,000. For a complete venture effort exceeding $4.2 million, Elementum 3D and its consortium companions will commit a minimum of 50% of the quantity as a value share. This system outcomes will probably be shared with America Makes members and the U.S. Authorities.

Named “Proliferation of AM Supplies Datasets,” this initiative seeks to create thorough materials property datasets for aluminum and nickel alloys, focusing on the acceleration of AM adoption in essential sectors like aerospace, protection, automotive, and vitality. Taking the lead on this venture, Elementum 3D will collaborate with companions together with Battelle, Castheon, Dyndrite Company, Eaton Company, EOS North America, Incodema, Nationwide Institute for Aviation Analysis, Product Analysis Programs (PES), The Ohio State College Middle for Design and Manufacturing Excellence, and Westmoreland Mechanical Testing and Analysis.

Dr. Jacob Nuechterlein, Elementum 3D President and Founder mentioned, “America Makes’ push to advance AM materials datasets is monumental for the manufacturing trade. It stimulates larger confidence in high-strength aluminum print high quality and broadens the AM provide chain. We’re excited to hitch forces with the opposite awardees. Collectively, our expansive data and experience in supplies growth establishes the way forward for AM supplies.”

Business leaders unite to advance steel AM supplies

First introduced in August 2023, this venture goals to reinforce AM materials datasets by rigorously documenting, statistically grounding, and diversifying info for industrial relevance. As part of this venture, Dyndrite will present copies of its LPBF Professional software program to allow speedy construct preparation, supplies, and course of growth, and report technology for {qualifications} for the EOS steel 3D printing machines chosen for this effort.

LPBF Professional will largely automate the method of producing additive materials knowledge units, historically a tedious guide activity. The software program will even enhance the method of speaking methodology and attaining repeatable outcomes, a historically user-error-prone course of.

Different events from the consortium will even be actively offering their experience for this venture. PES is partnering with Elementum 3D to assist America Makes in producing design-allowable databases for additively manufactured aluminum. PES, a long-time supporter of Elementum 3D and America Makes, goals to contribute its experience in mechanical, metallurgical, and chemical characterization to speed up the combination of A7050-RAM2 aluminum into additive manufacturing.

Eaton Company will collaborate to develop a design allowable dataset for A7050-RAM2, aiming to expedite superior AM options for the aerospace sector. Eaton brings in depth expertise in statistically primarily based materials allowables for numerous steel additive manufacturing processes, meaning to information aerospace product qualification expectations.

In response to Elementum 3D, the demand from producers for on-demand parts necessitates light-weight, high-strength aluminum supplies with superior fatigue and stress corrosion cracking resistance. Because of this, the A7050-RAM2 aluminum feedstock from Elementum 3D secured the gold medal within the “Materials Hurdles” occasion on the 2020 US Air Pressure Superior Manufacturing Olympics, additional highlighting its noteworthy attributes.

Elementum 3D propels AM innovation

In alliance with Elementum 3D, NASA accomplished the 3D printing and testing of a novel rocket engine nozzle underneath the RAMFIRE venture. The weldable aluminum, A6061-RAM2, was used to develop the nozzle which possesses the required heat-resistant properties for rocket engines.

With its low density, the 3D printed RAMFIRE nozzle is lighter than typical ones, enabling deep house missions with heavier payloads. The one-piece design, incorporating inner channels, minimizes manufacturing steps, reduces bonds, and permits large-scale engine element manufacturing in days. This venture was funded by NASA’s House Know-how Mission Directorate (STMD).

Beforehand, Elementum 3D acquired Nikon SLM Options‘ NXG XII 600 and entered an AM materials growth settlement with the corporate. This partnership was aimed toward increasing additive manufacturing, showcasing Elementum 3D supplies, and enabling Nikon SLM Options to reinforce the NXG XII 600’s materials portfolio. The partnership addressed challenges in aerospace industries and aimed to develop and market Elementum 3D’s supplies to be used in Nikon SLM Options’ machines.

What are the 3D printing developments to be careful for in 2024?

What 3D printing developments do the trade leaders count on to see this yr?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

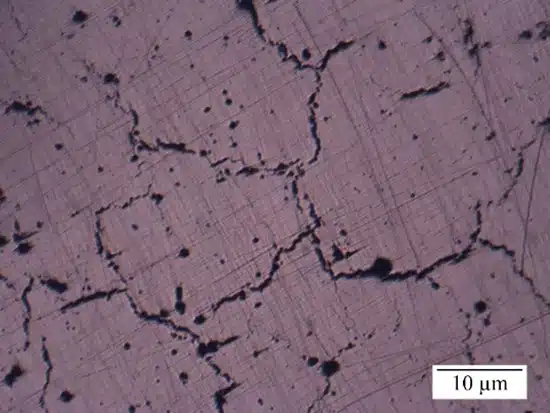

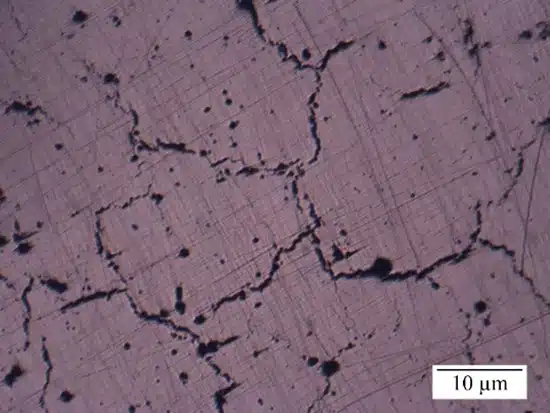

Featured picture exhibits an optical micrograph of Elementum 3D’s additively manufactured (3D steel printed) A7050-RAM2 aluminum 7050. Microstructure with RAM additions expressing the absence of sizzling tearing and minimized porosity. Photograph through Elementum 3D.