Main hotend producer E3D has partnered with US-based artificial model DiamondBack to deal with the rising calls for for specialised filaments.

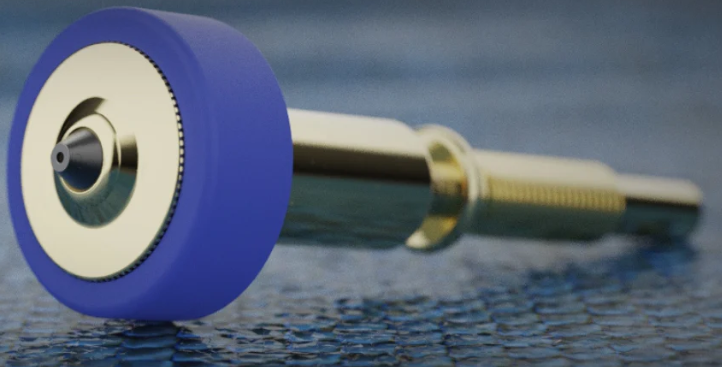

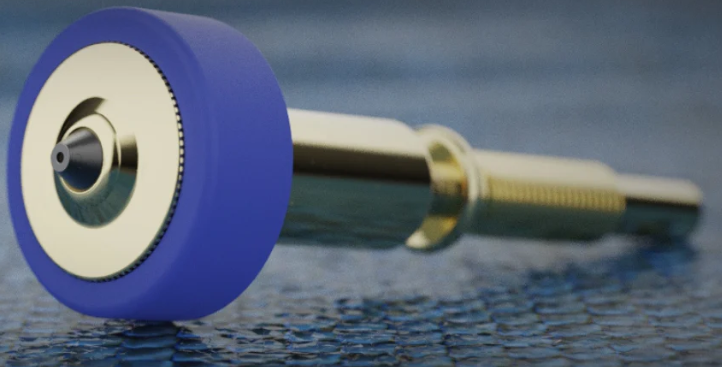

This alliance has launched a brand new product, dubbed Revo DiamondBack nozzle, designed to cater to the challenges posed by filaments infused with fiber, steel, and ceramics. DiamondBack nozzles, constructed from Polycrystalline diamonds, characterize a departure from standard jewelry-grade diamonds. In contrast to single-crystal diamonds, these nozzles incorporate a number of tiny diamond crystals with a proprietary binder, lowering brittleness whereas retaining distinctive hardness. The manufacturing course of of those diamonds includes excessive warmth and strain, equal to “the whole weight of the Eiffel Tower focused on a 5-inch space,” says the corporate.

Engineered for sturdiness, effectivity, and excessive efficiency

The partnership leverages E3D’s ten years of expertise to supply a novel resolution throughout the Revo ecosystem. The Revo DiamondBack nozzles allow tool-free, room-temperature modifications, guaranteeing extended printer operation at most effectivity. The fabric’s low coefficient of friction, complemented by a sophisticated nozzle tip, facilitates ultra-smooth layering with an inherent ironing-like property for cleaner high surfaces.

Appropriate with numerous Revo fashions, together with Revo Hemera, Revo Voron, and Revo Prusa MK3, the DiamondBack nozzles weigh 8g and accommodate a filament diameter of 1.75mm. This collaboration represents a big step ahead in assembly the evolving wants of the 3D printing neighborhood, introducing a nozzle resolution engineered for sturdiness, effectivity, and excessive efficiency, says the corporate.

Nozzle applied sciences in 3D printing

Industrial 3D printer producer Liqtra unveiled its LIQTRA FX-7 Professional 3D printer that includes multi-nozzle expertise, using as much as seven nozzles in a single print head. Managed individually, the expertise enhances productiveness by as much as 300% and will increase half energy by 37%, sustaining geometric element. The LIQTRA planning software program, an AI-powered multi-nozzle slicer, optimizes half orientation, units course of parameters, and manages particular person nozzle management.

Belgian startup Sculpman launched its patented ‘Variable Nozzle Expertise‘ for extrusion-based 3D printing. Departing from conventional fixed-size round nozzles, Sculpman’s design includes a constantly variable rectangular opening, permitting it to deposit flat tracks as much as 10mm in width. This resolution permits quicker print instances, lowering hours to minutes. In contrast to fastened cylindrical tracks, Sculpman’s expertise eliminates wave patterns, bettering layer alignment and adhesion. The system is about to supply construct charges of as much as 500cm3 per hour.

Learn all of the 3D Printing Business protection from Formnext 2023.

Voting has now began for the 3D Printing Business Awards 2023. Solid your vote now!

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing business? Go to 3D Printing Jobs for a number of roles within the business.

Featured picture exhibits Revo DiamondBack nozzle. Photograph by way of E3D.