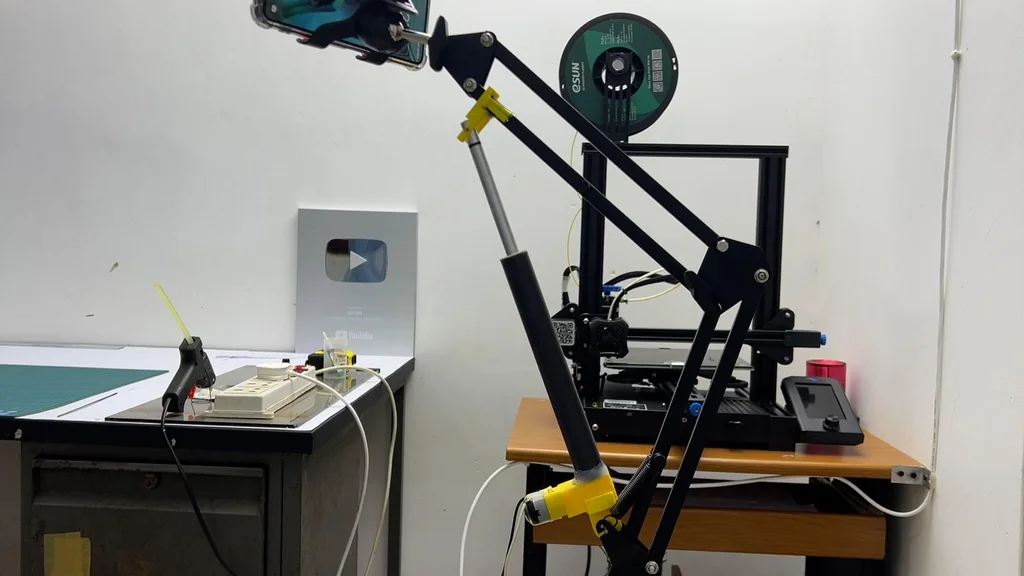

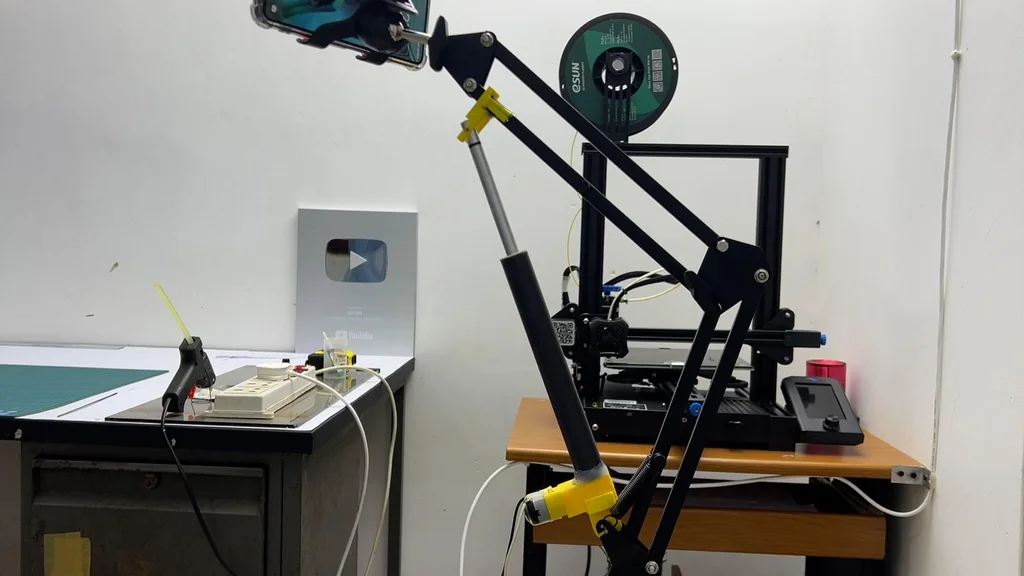

Within the area of electrical movement, motors usually take the highlight, leaving linear motion seekers in a quandary. Conventional choices like electromagnetic solenoids pose drawbacks (largely value associated), pushing fanatics to discover options. Enter DIY linear actuators, an answer by a maker by the identify of “PHYTION”, who has demonstrated the creation of a home made linear actuator utilizing economical parts and 3D printed parts.

Linear actuators, with variations like hydraulic, pneumatic, and electrical sorts, cater to numerous wants. PHYTION’s tutorial focuses on an electrical variant using a lead screw mechanism paying homage to a 3D printer’s Z-axis. This ingenious design, though sacrificing velocity for torque, ensures environment friendly conversion of rotary movement to linear drive.

The tutorial emphasizes cost-effectiveness, using customary nuts, primary threaded rods, aluminum tubes, and PVC pipes, all available from a ironmongery store. An reasonably priced electrical gear motor gives the required rotary enter, whereas 3D printed parts function structural help and mounts.

Fabricating this linear actuator primarily includes 3D printing the parts, slicing tubes to dimension, and assembling with adhesive. Whereas not supposed for heavy-duty duties, this DIY creation proves adept for robotics fanatics, providing commendable torque and precision, albeit requiring further {hardware} for place detection.

The DIY linear actuator venture illuminates the potential of merging affordability with performance. As fanatics delve into customized movement techniques, the long run holds promise for extra tailor-made options at a diminished value, due to the accessibility of 3D printing and different off-the-shelf applied sciences.

Supply: hackster.io

Come and tell us your ideas on our Fb, X, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.