International commerce group Additive Producer Inexperienced Commerce Affiliation (AMGTA) has printed a examine highlighting the environmental advantages of additive manufacturing throughout the vogue trade.

Titled ‘Comparative Evaluation: 3D Materials Jetting vs Conventional Strategies for Designer Luxurious Items’, the year-long examine analyzed the cradle-to-gate environmental affect of a 3D emblem hooked up to the heel of a luxurious athletic shoe.

The report discovered that the 3D printed part, produced by way of materials jetting, generated a a lot smaller environmental affect than the half manufactured with conventional processes.

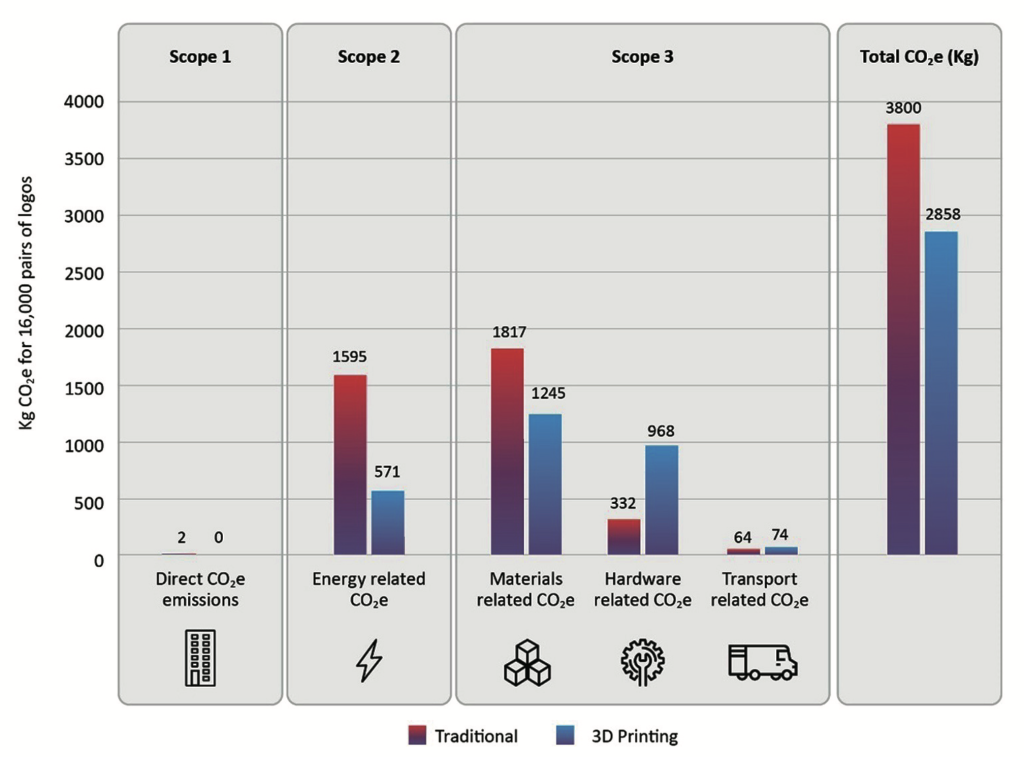

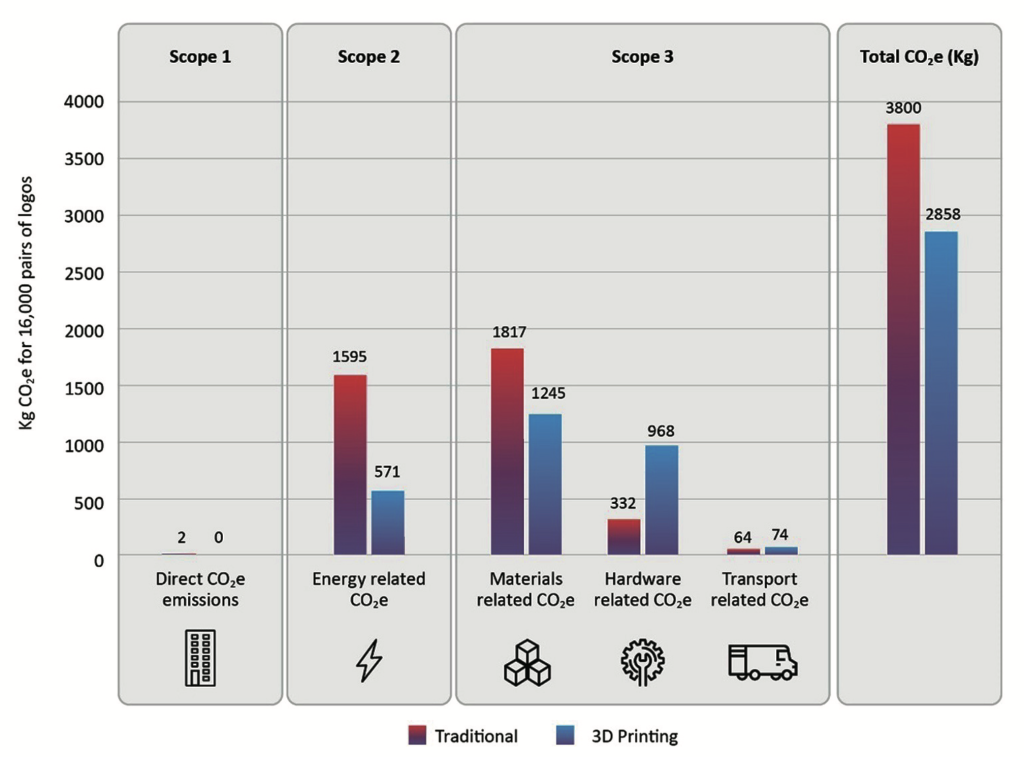

Actually, The 3D printed part enabled a 24.8% discount in CO2e emissions, and a 48% discount in inventory materials when in comparison with its historically manufactured counterpart.

Commissioned by the AMGTA, the examine was carried out by UK-based additive manufacturing consultancy Reeves Perception in collaboration with 3D printer producer Stratasys, Italian luxurious vogue agency Sample Group and its subsidiary, Dyloan Bond Manufacturing unit.

“We’re happy to problem the third physique of analysis in a collection of independently commissioned papers designed to disclose the environmental advantages of additive manufacturing adoption. We’re dedicated to advancing the analysis and publication required to raised perceive the sustainable worth of AM applied sciences as a part of the manufacturing cycle for broad enterprise circumstances,” commented Sherri Monroe, the AMGTA’s Government Director.

“This collaborative examine with Stratasys and Sample Group, assessing the affect of a print-to-textile course of, is our first analysis endeavor involving polymer. It delivers vital information that helps the worth of AM to affect one of the traditionally polluting industries on the planet.”

Stratasys CEO Dr. Yoav Zeif added, “This examine showcases how the adoption of our superior AM providing empowers prospects to ship manufacturing options that enhance their affect on the setting and on the similar time ship aggressive benefit by innovation in manufacturing for design.”

How was the examine carried out?

Commissioned in 2022, the examine in contrast the manufacturing of a 3D shoe accent utilizing each conventional and additive manufacturing methods.

The standard multiple-step course of included 2D inkjet printing and thermal welding of injection molded elements with sheet polyurethane supplies. Then again, the additive manufacturing course of required considerably fewer steps, and included materials jetting utilizing photocurable liquid resins.

The examine evaluated and in contrast each processes, with a manufacturing run of 16,000 emblem parts for 8,000 pairs of sneakers. The additively manufactured elements have been produced utilizing the Stratasys Polyjet J850 TechStyle 3D printer.

The post-manufacturing evaluation thought of the environmental affect of the manufacturing processes and supplies used. The first evaluation metrics have been air, water, and land emissions. Within the report, air emissions are offered as International Warming Potential (GWP) measured in carbon dioxide equal items (CO2e).

It’s value noting that this examine didn’t present a full Life-Cycle-Evaluation (LCA) of the ultimate footwear. As a substitute, an in depth Life-Cycle-Stock (LCI) for the 3D emblem part manufacturing stage, resulting in eventual footwear manufacturing, was supplied.

All inputs to and outputs from the manufacturing stage have been evaluated on this examine. The inputs assessed have been power and uncooked supplies. The outputs embody emissions to air, water, and soil; strong waste technology; merchandise; and co-products.

Key findings of the examine

Finally, 3D printing utilizing materials jetting was discovered to provide 24.8% much less CO2e emissions than the normal manufacturing course of.

Throughout the 16,000 emblem parts, 3D printing delivered one metric tonne much less CO2e into the environment. The report additionally famous that bettering the effectivity and productiveness of the 3D printer might cut back these CO2e emissions even additional.

3D printing was discovered to require 49.3% much less materials by weight than the normal manufacturing provide chain, representing one-third of a metric ton much less of inventory materials. Total, the 3D printed accent options 50.5% much less materials than its conventional counterpart, leading to a extra lightweight last product.

The examine additionally famous that over 300,000 liters of water was required to historically manufacture the 16,000 emblem parts. This is because of the usage of a paper-backed PU sheet as the first binding agent. 3D printing required no water.

When it comes to power consumption, the normal injection molding and thermal bonding manufacturing approaches used 7,122 kWh {of electrical} power. Alternatively, materials jetting 3D printing solely required 2,548 kWh, 64% much less electrical energy than typical manufacturing.

Nevertheless, the examine highlighted that each typical and additive manufacturing processes generated round 150 kg of non-recyclable waste. The standard manufacturing additionally produced 131 kg of recyclable waste, with no recyclable waste streams related to the 3D printing method.

Furthermore, the normal manufacturing provide chain was discovered to have a barely decrease environmental affect than the 3D printing provide chain, with regard to transport-related emissions. This disparity was pushed by the longer distances related to transporting speciality resins, with conventional manufacturing utilizing native provide chain companions.

Calculating the sustainability of additive manufacturing

Additive manufacturing is actually seeing a rising deal with sustainability. Earlier this yr, AMGTA carried out an LCA evaluating conventional casting to binder jetting for an industrial half.

This LCA was carried out by the Yale College of the Setting (YSE) in collaboration with industrial 3D printer producer Desktop Steel and US-based “local weather innovator” Trane Applied sciences. Finally, binder jet 3D printing confirmed a 38% discount in greenhouse fuel emissions. This was pushed by diminished power demand throughout manufacturing.

Elsewhere, 3D Printing Trade attended AM Summit 2023, Scandinavia’s largest additive manufacturing convention. Right here, there was a major deal with sustainability and 3D printing.

Through the Copenhagen-based convention, Throughout AM Summit 2023, Marie Langer, CEO of 3D printer producer EOS, outlined the advantages of the corporate’s 3D printing Value and Carbon Calculator. This on-line instrument offers clear 3D printing price and carbon evaluation, visible analytics, price sensitivity evaluation, report technology, data-driven design, and customised circumstances for buyer pricing.

Based on Langer, the calculator makes it simple “for our prospects taking a look at particular purposes to calculate carbon emissions and in addition share the pricing to actually consider the inexperienced enterprise case.”

Equally, Danish AM Hub, the organizers of AM Summit, has developed its personal CO2e calculator. This instrument instantly compares the CO2e emissions of 3D printing with typical manufacturing for a set part. Designed with simplicity in thoughts, this calculator outputs one quantity – indicating the quantity CO2 saved or gained through the use of additive manufacturing.

The Danish AM Hub CO2e calculator was leveraged by Danish-based industrial equipment agency Danfoss. Utilizing this instrument, the corporate carried out a CO2e calculation on a metallic crossbar part. 3D printing was discovered to be 30% extra sustainable than CNC machining, saving 400 kg of CO2 per variant.

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture reveals the heel spur emblem part. Picture by way of AMGTA.