Additive manufacturing software program firm 1000 Kelvin has partnered with Norwegian Defence Analysis Institution (FFI) spin-off Fieldmade to allow the speedy deployment of 3D printers in energetic fight zones.

Introduced throughout the Navy Additive Manufacturing (MilAM) summit and expertise showcase, this collaboration will reportedly improve strategic readiness and operational capabilities within the army sector.

This partnership will see 1000 Kelvin’s AMAIZE platform combine with Fieldmade’s deployable additive manufacturing options, together with its NOMAD collection of transportable 3D printing modules.

The businesses declare that this mix will allow these on the battlefield to start out 3D printing as quickly because the module arrives on web site. This permits customers to shortly adapt to operational manufacturing wants.

Going down in Florida between 16-17 January, MilAM is marketed as the most important army, aerospace, and protection additive manufacturing occasion in North America.

“Our imaginative and prescient is to make deployable 3D printing as straightforward as utilizing a merchandising machine. The combination of 1000 Kelvin’s AMAIZE into our merchandise is a big step in the direction of this objective,” commented Fieldmade CEO, Jostein Olsen.

“By combining our strengths, we’re not simply advancing expertise; we’re offering options that may save time, prices, and in crucial army situations, even lives,” added Omar Fergani, CEO and Co-Founding father of 1000 Kelvin.

AMAIZE and NOMAD to mix on the battlefield

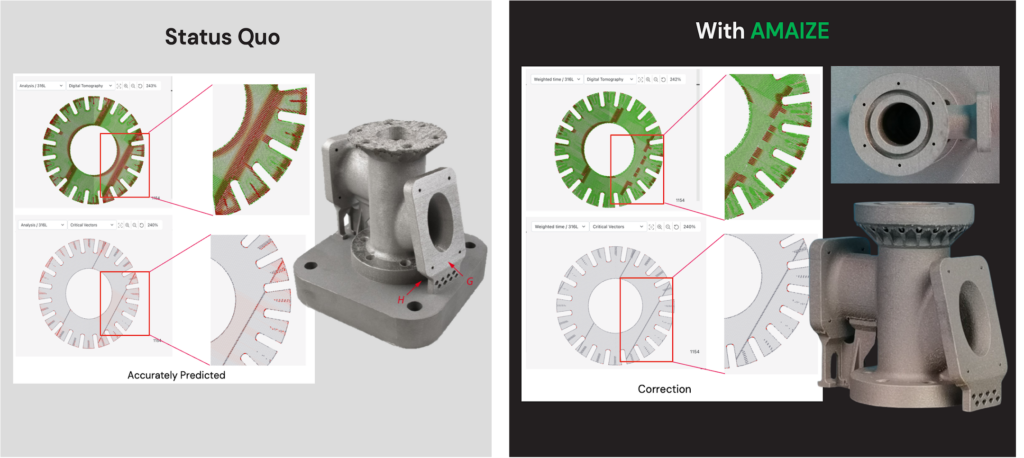

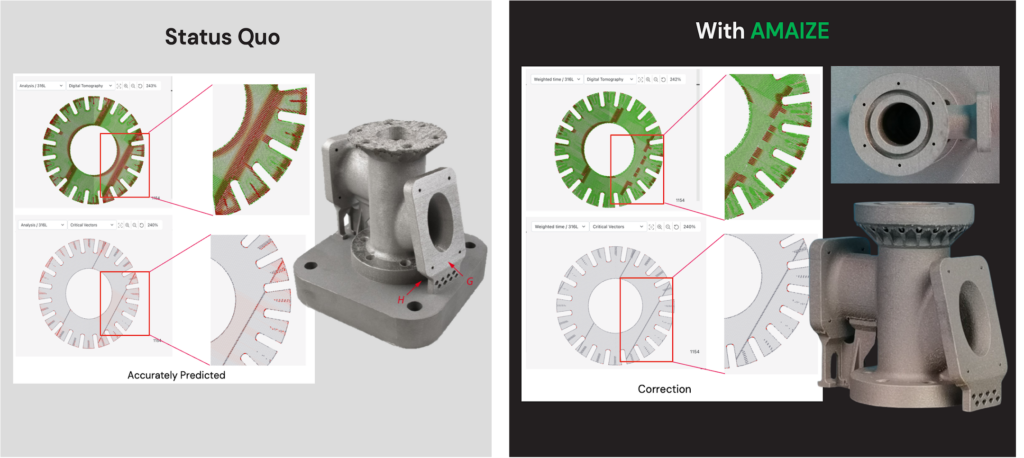

1000 Kelvin’s AMAIZE software program combines synthetic intelligence (AI) with physics and manufacturing knowledge to offer an ‘AI-copilot’ to additive manufacturing engineers. Launched to market at Formnext 2023, AMAIZE creates optimum 3D print ‘recipes’ which guarantee components are 3D printed appropriately the primary time.

As soon as a 3D print file is uploaded to the AMAIZE cloud, the software program analyzes the half and mechanically addresses any thermo-mechanical points by optimizing scan technique and course of parameters.

This streamlined strategy is claimed to eradicate the necessity for costly finite simulation software program, minimizing the necessity for a number of bodily iterations within the course of. This limits materials waste, value, and power utilization. 1000 Kelvin has already introduced preliminary AMAIZE collaborations with 3D printer producer EOS and an unnamed California-based rocket launch supplier.

AMAIZE is claimed to seamlessly align with Fieldmade’s deployable additive manufacturing expertise. Launched again in 2016, Fieldmade affords totally built-in additive manufacturing techniques which can be simply deployable, and optimized for army use. Its NOMAD microfactories incorporate a collection of army customary cellular models possessing ISO/CSC licensed containers, 3D printer cells with environmental management, totally damped 3D printer bases (air, seas, and land transportable), and high quality assurance and inspection instruments. Powder mattress fusion, VAT polymerization, Direct Vitality Deposition (DED), and materials extrusion 3D printing applied sciences are all supplied by NOMAD.

Previously, FIeldmade has collaborated with the Norwegian Armed Forces and different protection entities. The corporate has additionally efficiently demonstrated its expertise in discipline workout routines and industrial developments within the power sector.

1000 Kelvin and Fieldmade are assured that this collaboration will allow speedy, high-quality half manufacturing on the level of want in all fight environments.

Additive manufacturing on the entrance strains

Throughout the world context of rising battle, additive manufacturing is more and more being utilized on or close to the frontlines to supply components of consequence. Final 12 months, Australian steel 3D printer producer SPEE3D equipped seven WarpSPEE3D 3D printers to Ukraine, as a part of a US Division of Defence’s (DoD) Ukraine Safety Help initiative.

The corporate, which specializes within the manufacturing of defense-optimized cold-spray 3D printers, additionally supplied a 15-day coaching program to Ukrainian army personnel. In an interview with 3D Printing Trade, Calum Stewart, SPEE3D’s Director of Protection Applications, acknowledged that SPEE3D expertise helps to get “extra tools within the struggle, extra of the time.”

The mobility of the WarpSPEE3D 3D printers, that are put in inside a regular delivery container, makes them particularly properly suited to fight environments. “You’ll be able to decide it up, put it on the again of a truck, put it down, set it up, and have it up and operating in 45 minutes.” In keeping with Stewart, while achievable with chilly spray, this stage of pace just isn’t attainable with laser-based 3D printers.

Equally, Industrial 3D printer producer Essentium partnered with KVG to offer 3D printing options, coaching, and manufacturing instruments to the Ukrainian army. Simply 96 hours after approval, Essentium and KVG had efficiently deployed quite a few superior Excessive-Velocity Extrusion (HSE) 3D printers all through Ukraine.

The companions acknowledged that the 3D printers will bolster Ukraine’s protection response capabilities by shortly manufacturing a spread of mission crucial components on the level of want. Like SPEE3D, Essentium additionally supplied on-site coaching to make sure steady and expedited half manufacturing.

“In occasions of battle, collaboration and agility can create essential strategic benefits. Our partnership with Essentium is an ideal instance. It has allowed us to quickly deploy important expertise and sustainable mission help instruments in Ukraine,” commented KVG President Elisha Abbott.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits Fieldmade’s NOMAD micro manufacturing unit. Photograph through City Alps.