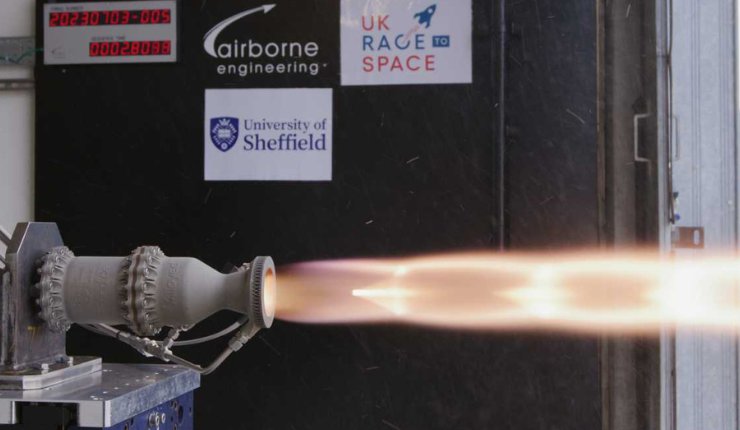

In July 2023, college students on the College of Sheffield broke a report. A liquid rocket engine, just like the sort utilized by SpaceX, was constructed beneath the Sunride Undertaking and efficiently fired as a part of the Race to House initiative. What was particular about this one? It’s believed to be the primary metallic 3D printed rocket engine to be constructed and efficiently examined by college students within the UK.

The ‘SunFire’ engine, which the Sunride workforce says is essentially the most highly effective studentbuilt engine of its variety, makes use of each gas and an oxidiser quite than inhaling oxygen like a jet engine. The engine can also be regeneratively cooled, which implies it makes use of gas to chill the combustion chamber earlier than it’s burnt, which will increase effectivity and saves weight.

The Sunride workforce says that the College of Sheffield’s Royce Discovery Centre, a analysis facility growing next-generation supplies to satisfy UK manufacturing wants, was ‘instrumental’ in trialling the laser powder mattress fusion metallic 3D printing that was used to construct the engine. The engine was machined after printing by the college’s Superior Manufacturing Analysis Centre (AMRC) and College of Engineering.

Henry Saunders, who served as a Design Engineer on Undertaking Sunride, and is now learning for a PhD in additive manufacturing on the college, instructed TCT: “I bought into steel additive manufacturing via wanting to construct this engine. I reached out to a professor who I knew had some steel 3D printers on the uni, Iain Todd, who I ended up doing my PhD with. That venture began with the purpose of constructing the primary student-built, regeneratively cooled liquid rocket engine within the UK. I went about making an attempt to get different masters college students to do different areas of the venture, so we recruited folks to return in alongside us and do different areas of the rocket engine design such because the CFD for cooling channels, combustion stability design as nicely, so we had tutorial assist for his or her last yr tasks.”

Chatting with TCT about pursuing a PhD in additive manufacturing, Saunders added: “I had a job provide from an organization known as Alloyed, after which I had a PhD provide as nicely, and I simply felt like there was a lot extra I may study with additive, and the services at Sheffield are actually good to get hands-on expertise. There’s Aconity3D machines, Renishaws and a few DED programs as nicely. There’s heaps to mess around with and it’s a very cool atmosphere to be in.”

The engine was constructed by Saunders and his friends over a interval of two years outdoors of their research as a part of the College of Sheffield’s House Initiative, a programme to assist STEM college students use their abilities to sort out a number of the largest issues within the business after commencement. The rocket was then fired as a part of the Race to House initiative, which concerned eight different groups, seven of which had rockets that have been efficiently fired.

The Race to House initiative, which was launched by Dr. Alistair John, Deputy Director of Aerospace Engineering at The College of Sheffield alongside Saunders, goals to supply college students with sensible experiences fixing engineering issues, via hands-on expertise of designing, manufacturing and testing rocket engines. In keeping with the initiative’s web site, it’s constructing a “UK-wide house coaching infrastructure”, in addition to addressing variety points comparable to an absence of alternatives for girls, ethnic minorities, and people from deprived backgrounds.

Dana Arabiyat, presently at Rolls-Royce, however who beforehand labored as a Design Engineer on Undertaking Sunride and later Undertaking Supervisor, instructed TCT: “We’ve been constructing rockets for just a few years in Undertaking Sunride, and to the touch on propulsion was a vital step to extend a pupil’s data and expertise and get them prepared for the house business within the UK. We thought graduates within the UK lacked that sensible data, and we solely realized rocket concept in college. We thought to have college students get hands-on expertise in constructing an precise liquid rocket engine can be invaluable, it’s going to make us all stand out. Many individuals within the business nonetheless haven’t skilled what we now have engaged on this engine on the college. You’ll be able to inform from how nicely our college students are doing now of their careers, that we do have a bonus, we gave them the data they should excel of their profession. I’m presently at Rolls-Royce, and I’m going to begin working in combustion, the truth that I’ve achieved my masters dissertation on a liquid rocket engine combustion chamber offers me the sting.”

Dr. Alistair John added: “The house sector wants extra extremely expert graduates. So we have to expose our college students to sensible engineering. Plenty of aerospace levels are fairly good on the theoretical facet, however they get a restricted expertise of truly constructing and testing one thing actual. So, to have the ability to go and really take a look at the rocket engine, make errors, take a look at the rocket, truly fireplace it and see what occurs, then iterate is a implausible expertise, and it’s actually what this nation wants extra of. On prime of that, it’s costly, but when you’ll find the funding and help, that’s clearly essential, however what it does is give them the power to essentially dream huge.”

TCT requested each Arabiyat and Saunders what the second was like once they bought to efficiently fireplace the SunFire engine on the primary try. Arabiyat stated: “Simply the opposite day I used to be with a bunch of mates and I used to be requested: ‘In case you may relive a second in your life, what would it not be?’ For me, it could be the second I truly noticed the flames popping out of the rocket, like I can’t imagine it truly labored. It’s a second I actually need to re-live on repeat. We have been being instructed: ‘Don’t fear if it doesn’t work’, and so they simply saved telling us to not count on a lot from the primary strive. It was two years of laborious work ready for this second. We have been all simply one another like, we did it, we truly did it.”

Saunders answered: “It was fascinating truly, as a result of I used to be as a result of be on a flight. We have been in Oxford, and I had a flight from Gatwick that night to go and do an experiment in France the next week. So, I used to be on fairly a decent schedule to get it achieved, then it labored first time. It was unbelievable actually. There’s a video of us from the bunker, we needed to be in a management bunker, and so we have been filming the screens, and we’re simply swearing and going loopy. I used to be fairly shocked the best way it turned out.”

3D printing proved helpful in bringing the design of the SunFire engine to life, because it allowed for the manufacture of small pipes for the cooling channels, built-in into the wall of the combustion chamber. Regeneratively cooling engines have been manufactured with out 3D printing, however based on Dr. Alistair John, the cooling channels have been ‘brazed on’ to the combustion chamber, whereas with a totally 3D printed rocket engine, the channels may very well be built-in and a part of the design of the general engine.

The SunFire engine needed to be printed in two components due to the peak, and sealed along with a gasket. Dr. John instructed TCT that the workforce had worries that the engine would leak fluid, or fireplace would come out of the facet, however the sealing method labored.

Summing up her expertise on the venture, Arabiyat instructed TCT: “This has been a record-breaking competitors the place we had seven out of eight groups efficiently get superb flames out of their engines with the shock diamonds, it was simply unbelievable what we managed to realize. An unbelievable journey of studying, failing and reiterating, and venture hand over as nicely, which is an excellent ability. Loads of occasions you get began with one thing after which when these folks graduate the venture dies out. From design to check, the SunFire engine took two years to finish, so handing over to the following masters college students, passing on the data was a vital a part of the method.”

The SunFire engine was fireplace examined at Airborne Engineering on the Westcott House Cluster and 3D printed on the Satellite tv for pc Purposes Catapult. The Race to House initiative can also be believed to have set an unofficial world report itself, for the best variety of completely different hybrid/liquid rocket engines hot-fired for the primary time on one web site in a single week.

Arabiyat additionally participated in one other record-breaking launch as a part of the SunRide Undertaking in 2019, when a workforce of scholars fired a rocket 36,274ft into the sky, beating the earlier UK report, which stood for 19 years, by virtually 2,000ft. This rocket was named Helen in honour of The College of Sheffield’s Dr. Helen Sharman OBE, the primary Briton in house.