Shenzhen-based 3D printer producer Anycubic not too long ago introduced a brand new addition to its desktop FDM 3D printer portfolio, the Kobra 2 Max.

Providing notable upgrades from the earlier Kobra 2 mannequin, the Kobra 2 Max is optimized for high-speed, large-scale desktop 3D printing at an inexpensive value. Anycubic’s new 3D printer additionally stands out because of upgraded mattress leveling, extrusion, and cooling programs, in addition to its PID calibration and vibration compensation.

This text will spotlight our first impressions of the Kobra 2 Max, while outlining the important thing options and promoting factors of Anycubic’s newest high-speed 3D printer.

The Kobra 2 Max is out there to order for $549 by the official Anycubic on-line retailer.

Key options of the Anycubic Kobra 2 Max

Central to the Kobra 2 Max is its pace. In response to Anycubic, the Kobra 2 Max’s 500mm/s most 3D printing pace and 10,000mm/s² acceleration is 10x quicker than most mainstream FDM 3D printers available on the market. Certainly, the Kobra 2 Max’s really helpful 3D printing speeds of 300mm/s can reportedly fabricate a 3D Benchy in simply 18 minutes, 83% faster than different 50mm/s programs.

Excessive-speed 3D printing is aided by a high-performance Cortex-A7 1.2GHz processor. This presents robust computing energy for quick calculations, command execution, and motor management.

Anycubic’s new 3D printer can be notable for its substantial 500 x 420 x 420 mm construct quantity. With the Kobra 2 Max, customers can produce fashions with a quantity of as much as 88 liters in a single 3D print. This expanded 3D print dimension permits customers to discover extra complicated 3D prints, and bigger tasks not attainable on smaller desktop choices.

The Kobra 2 Max additionally presents connectivity to the brand new Anycubic APP. This permits distant connectivity, permitting customers to view the 3D printer’s standing in real-time. Upcoming updates are additionally set to allow on-line slicing and 3D printing, real-time video monitoring and time-lapse pictures, distant management and administration, and an open mannequin library operate module.

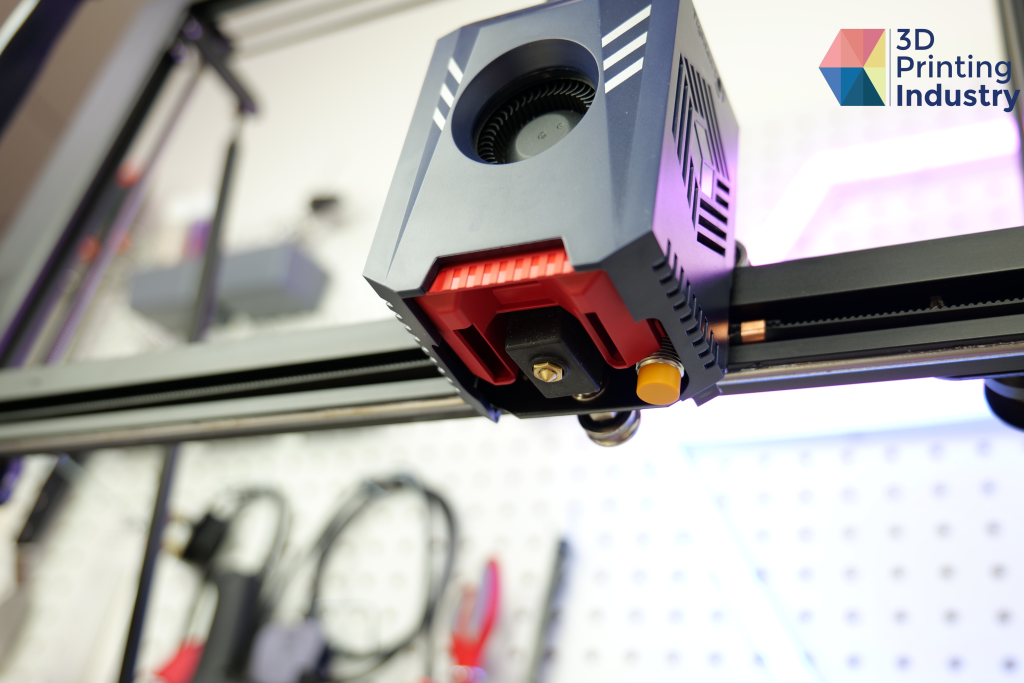

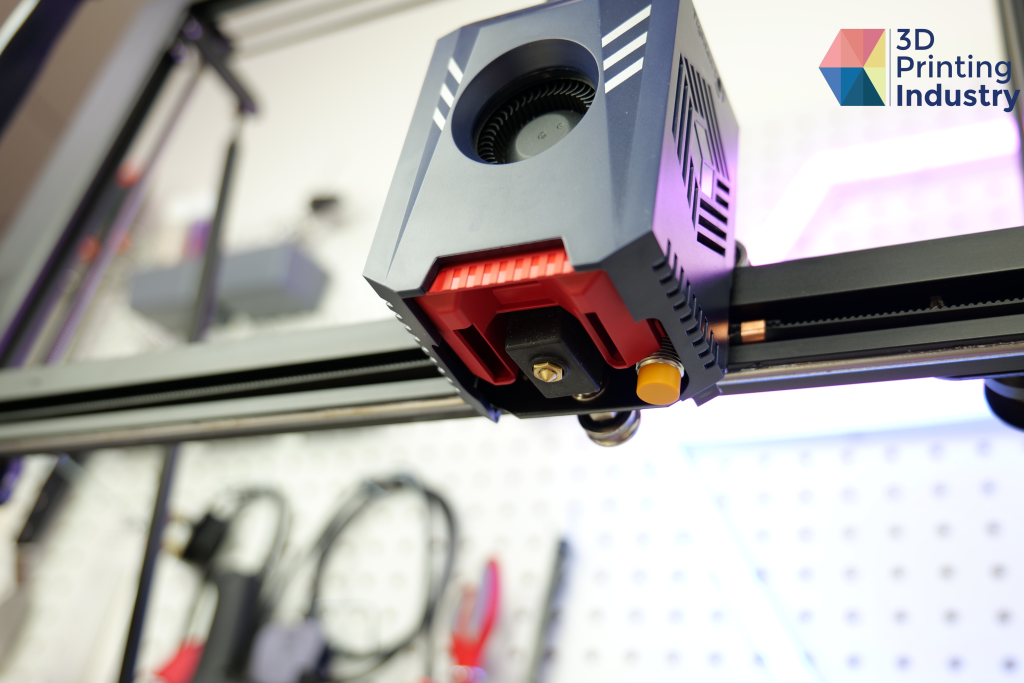

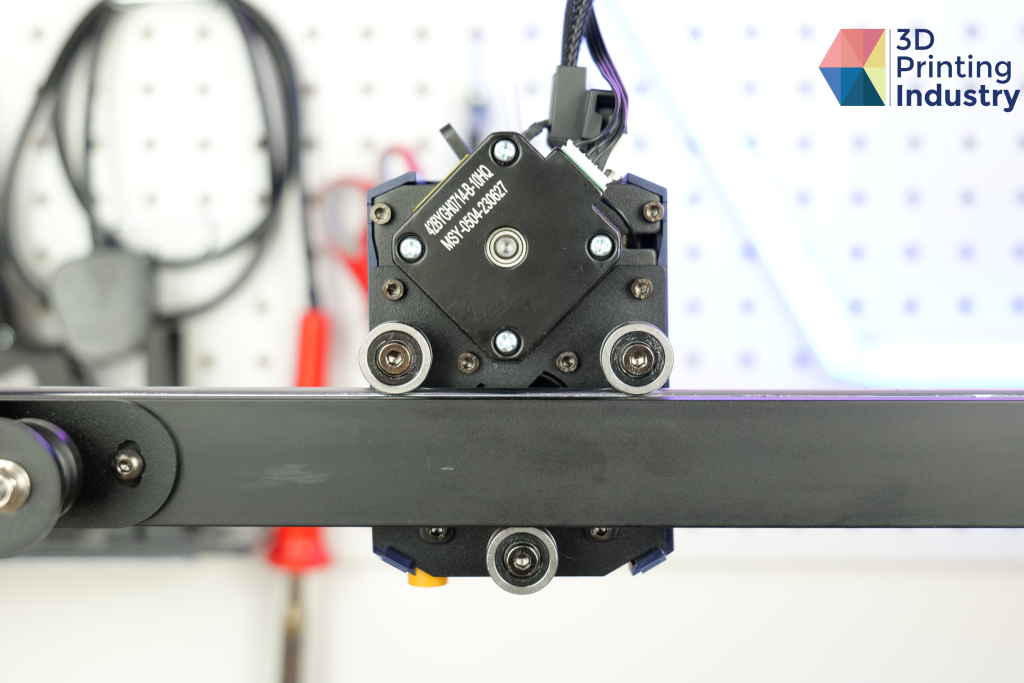

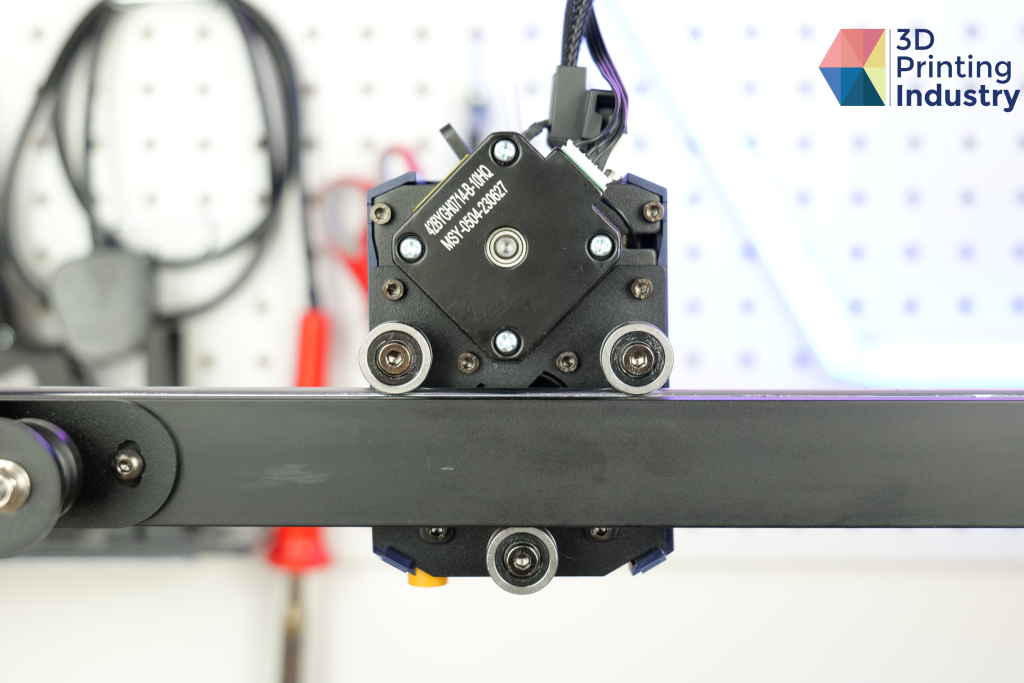

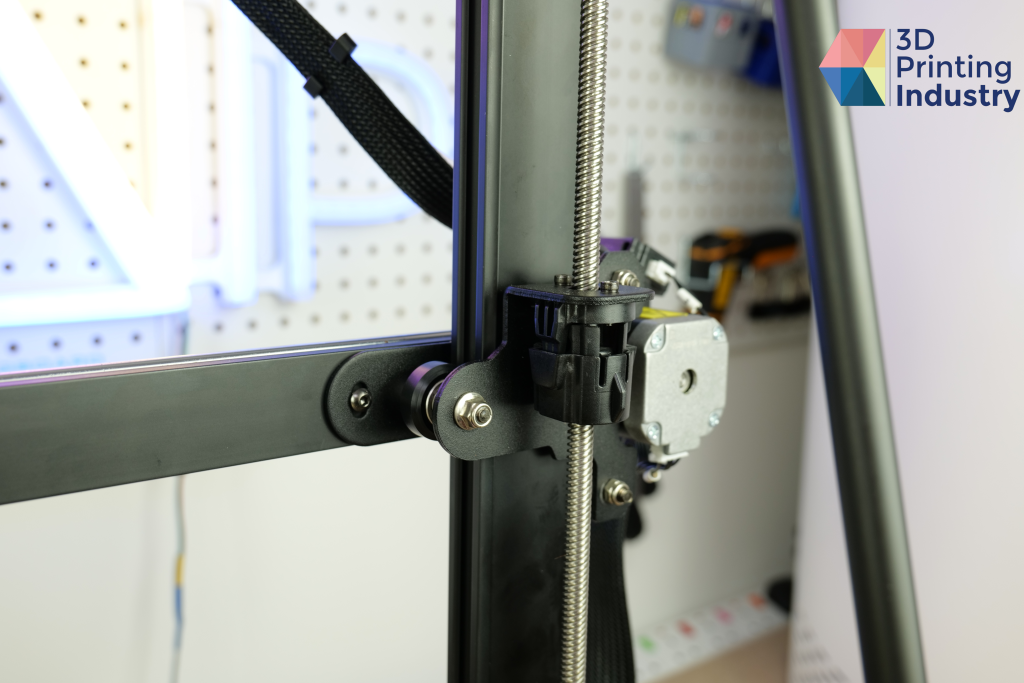

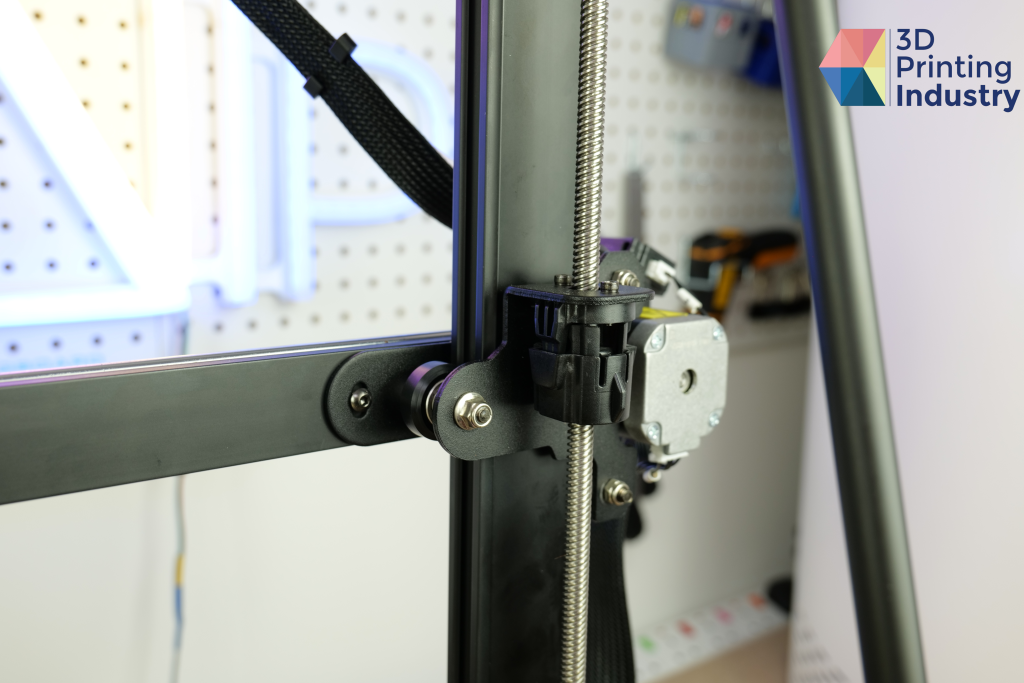

The Kobra 2 Max employs a brand new direct drive extruder coupled with a dual-motor dual-z-axis movement construction. This optimizes the flexibility of the 3D printer to convey supplies effectively and precisely. Environment friendly cooling can be ensured by the 3D printer’s 7,000 rpm/min high-speed cooling fan, which may be fairly loud throughout 3D printing. The Kobra 2 Max additionally helps a variety of supplies, permitting customers to 3D print with PLA, ABS, PETG, and TPU.

First impressions

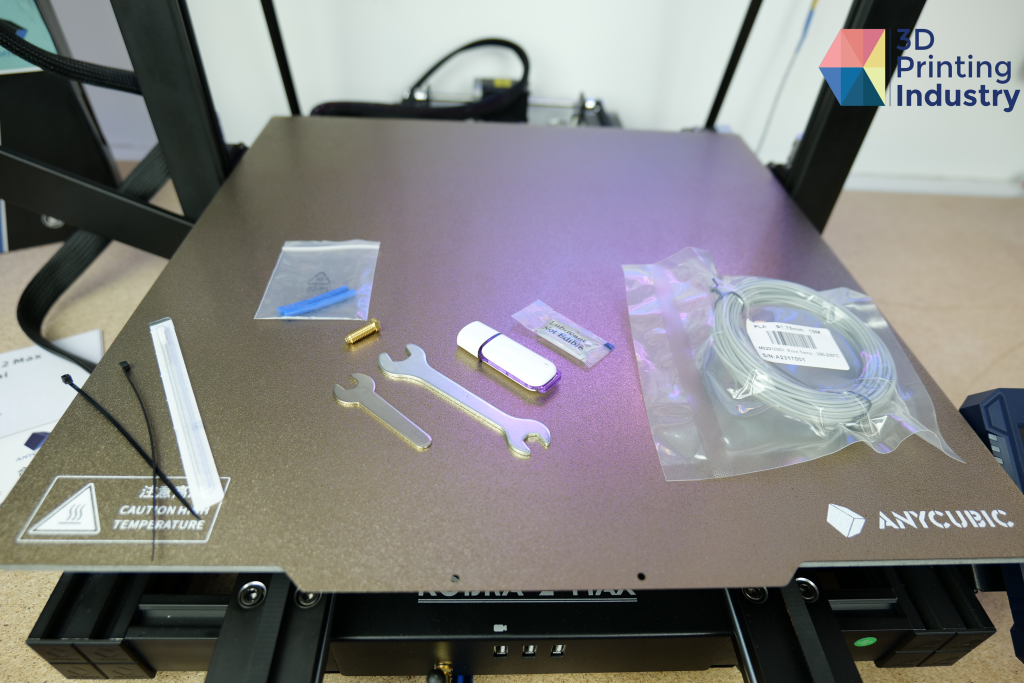

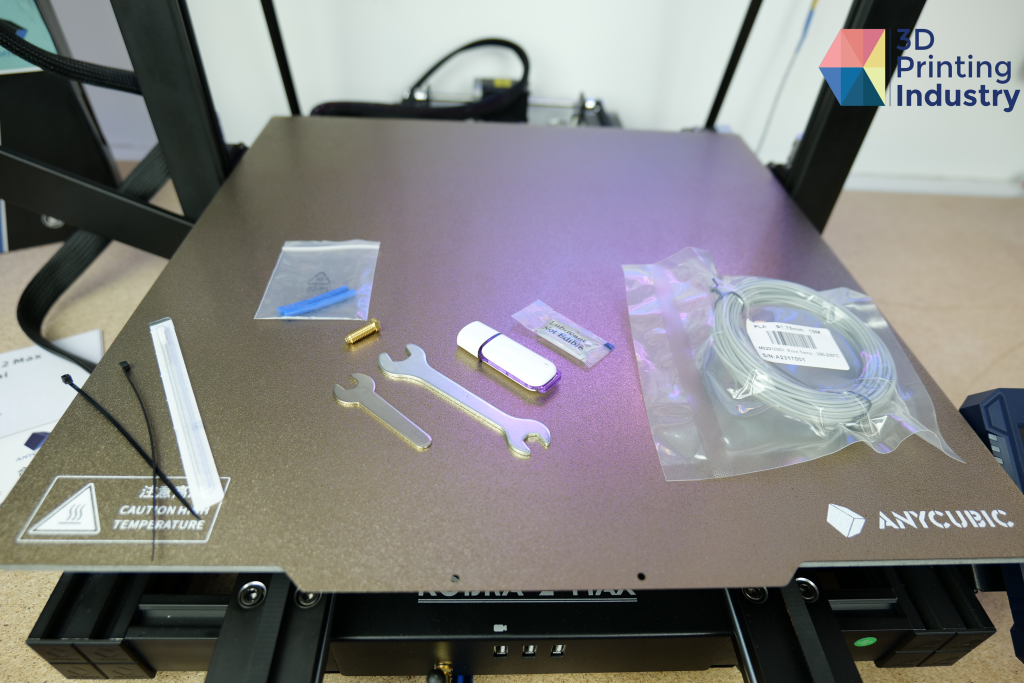

Out of the field, we have been largely impressed with the Kobra 2 Max. The 3D printer incorporates a examine, full metallic body which helps high-speed 3D printing. With good total construct high quality, the Kobra 2 Max is kind of a big open system which maybe seems much less tidy than different fully-enclosed programs. Nonetheless, given the 3D printers’ inexpensive value, Anycubic’s new 3D printer presents good worth for cash.

A double motor double Z-axis is included within the Kobra 2 Max, which additionally possesses double metallic spindles and SG15 bearings for high-quality, high-speed extruder motion.

Optimized for ease of use, the Kobra 2 max’s consumer interface is intuitive and straightforward to navigate. The 4.3-inch full-color touch-screen interface presents simple management and offers responsive performance.

Our workforce has been significantly impressed with the Kobra 2 Max’s ‘Vibration Compensation’ and PID calibration. With only one click on, the ‘Vibration Compensation’ characteristic offers resonance frequency detection on the X/Y axis, eliminating vertical and bracket strains for 3D print stability. ‘Circulate Management’ can be provided, compensating for retraction and refilling, making certain uniform and detailed outcomes.

The addition of a sensible Z-axis offset into the Kobra 2 Max’s computerized mattress leveling system can be a pleasant contact. This enables the 3D printer to compensate for Z-axis offset whereas supporting customized Z-axis compensation values. A chosen inductive sensor is included for the automated mattress leveling course of.

The spring metal magnetic construct plate is versatile, and permits for straightforward half removing. Nonetheless, we imagine this may very well be improved by the addition of grippers to additional safe the construct plate throughout 3D printing.

One small element that has stood out to us is the designated extruder cleansing pad. Earlier than every 3D print, the extruder is wiped in opposition to a small cleansing sq. situated above the highest proper nook of the construct plate, eradicating any undesirable residue. We see this as a chic answer to a standard 3D printing drawback.

Technical specs

| 3D Printing Expertise | FDM |

| Bodily Dimensions | 740 x 735 x 640 mm |

| Weight | 21kg |

| Construct quantity | 500 x 420 x 420 mm / 88L |

| 3D Printing Velocity | 500mm/s (Most)300mm/s (Typical) |

| X/Y-axis | Double Steel Spindle |

| Z-axis | Double Motor Double Z-axis |

| X/Y-axis Belt Tensioner | Included |

| Construct Plate | PEl Magnetic Spring Metal |

| Hotbed Temperature | ≤194F/90°C |

| Cooling Fan RPM | 7000rpm/min |

| Suitable Supplies | PLA/ABS/PETG/TPU |

| Mattress Leveling | New Anycubic LeviQ 2.0 Automated Leveling System (49-point) |

| Extruder | Anycubic Self-Developed Direct Extruder + Double Gears |

| Management Panel | 4.3″ LCD Contact-Management Display screen |

| Information Enter | USB ports x 3 |

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture exhibits the brand new Kobra 2 Max from Anycubic. Photograph by 3D Printing Trade.