Jayant Mathur, a PhD pupil at The Pennsylvania State (Penn State) College, is main a analysis challenge exploring the usage of immersive digital actuality (VR) software program in additive manufacturing.

3D Printing Trade just lately sat down with Mathur to be taught extra about this challenge, and the potential for VR inside additive manufacturing.

Performed by the college’s Made By Design Lab, this analysis seeks to evaluate the utility of VR as a coaching and design device for 3D printing.

“We’re more and more seeing an emergence of immersive VR headsets, and it’s changing into fairly frequent to see their position in engineering and design processes, and even manufacturing,” defined Mathur.

“How can we prepare folks to realize technical competency, and the way can we assist them get design instinct? How can we bridge these two seemingly completely different applied sciences to handle a standard objective that we all know is the limitation within the present trade?” Based on Mathur, that is the overarching problem that this challenge is hoping to handle.

“It’s a matter of attempting to determine the place within the additive manufacturing workflow VR matches greatest,” added Mathur. “As a result of we all know it has a spot, we simply want to determine the place that’s.”

The challenge is being directed by Nicholas Meisel, Affiliate Professor at Penn State College. It consists of cooperation from Professor of Engineering and Design in Manufacturing Timothy Simpson, and Professor Scarlett Miller, Administrative Fellow to the Govt Vice President.

Launched again in 2020, this challenge is about to run till Could 2024.

VR as an additive manufacturing coaching device

One key discovering from this analysis is that VR is a more practical coaching device for additive manufacturing than conventional computer-based strategies. “In relation to coaching folks, digital actuality is much extra intuitive as a modality than computer-aided know-how,” defined Mathur.

Mathur pointed to powder mattress fusion (PBF) and directed vitality deposition (DED) know-how as being effectively suited to the VR area. Marthur argues that, given the prices and dangers related to PBF, it isn’t a good suggestion to introduce someone with no hands-on expertise to this know-how. Nonetheless, coaching someone within the digital area, argued Mathur, can present the mandatory data and expertise to soundly deal with PBF 3D printers.

“There’s a massive distinction between studying with a non-immersive laptop display screen, versus studying with a digital actuality headset and controllers. What we now have discovered is that VR will be akin to actual, in-person situations,” defined Mathur.

The truth is, in line with Mathur’s analysis, people who use VR with industrial 3D printing techniques can acquire as a lot data as they might in the event that they have been proper in entrance of the 3D printer in actual life.

“That’s certainly one of our key findings. This tells us that digital actuality has a spot in our design and manufacturing workforce at this stage,” said Mathur. “This opens up many avenues for a way we take into consideration coaching processes, schooling, studying, and in addition put together the workforce to benefit from additive manufacturing.”

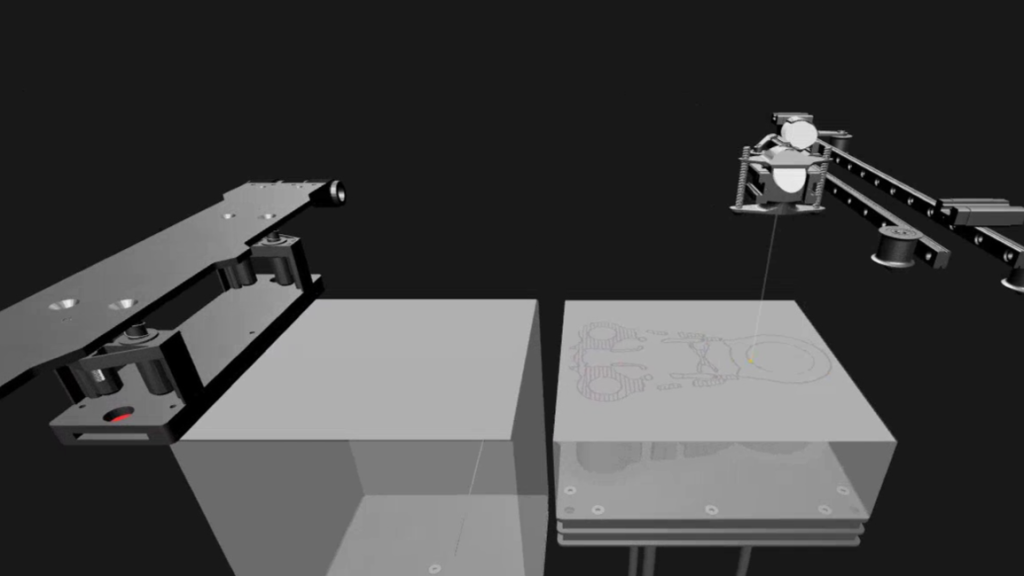

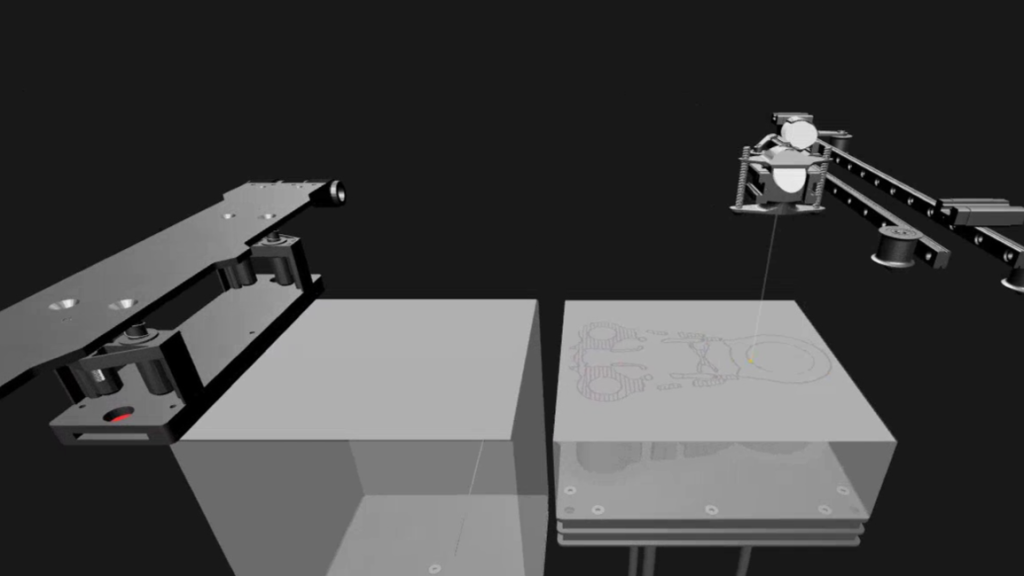

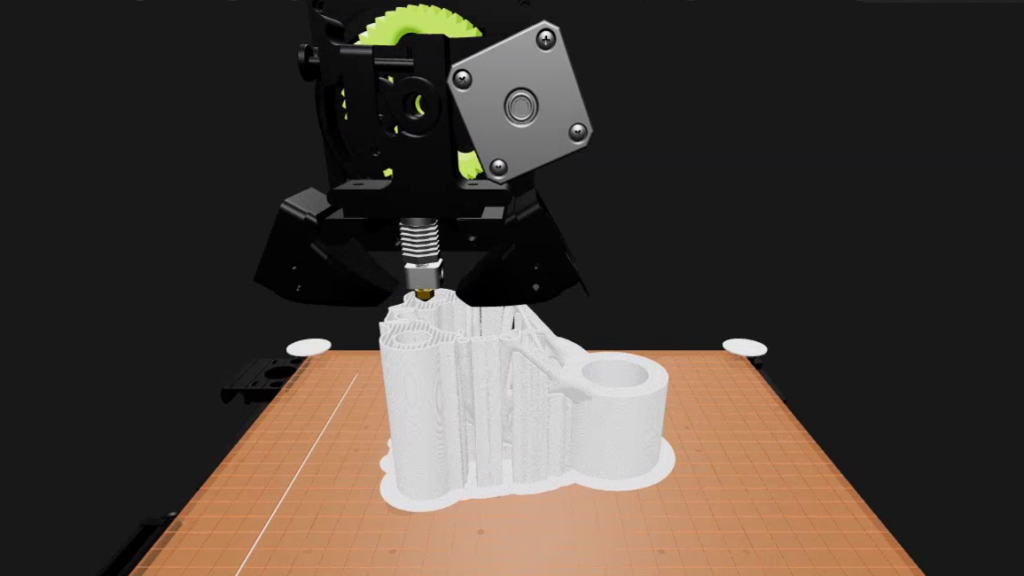

A person masses new powder into the feed bin of the Xact Metallic XM200C powder mattress fusion 3D printer. The video then jumps to visualizing the 3D printing of a component contained in the system. Video through Jayant Mathur.

Increasing design complexity in additive manufacturing

Based on Mathur, VR is just not restricted to coaching purposes in additive manufacturing. A further space being evaluated by the Penn State workforce is that of design for additive manufacturing (DfAM).

“Everyone knows the completely different geometric complexities that additive manufacturing can supply in our design processes. We try to determine if there’s a manner for us to visualise and consider these designs that may profit from spatial immersion,” defined Mathur.

The truth is, as with coaching purposes, Mathur claims that designers discover it simply as straightforward to make use of VR for CAD designing as with conventional laptop screens. “That’s actually attention-grabbing since you would assume that it could be troublesome or tedious to do design work with this know-how, but it surely isn’t.”

Mathur sees these findings as highlighting the potential for VR to extend additive manufacturing design complexity sooner or later. “As design complexity will increase, there could be a spot for digital actuality the place laptop screens are simply not sufficient as a result of they’re constrained and so they restrict the perspective,” defined Mathur.

What’s extra, Mathur believes that VR will prolong the usage of additive manufacturing by rising the arrogance and openness of designers to undertake 3D printing. In flip, it’s hoped that this may alter the ways in which designers strategy DfAM, enabling new design complexities within the course of.

“I really feel that, due to the capabilities that digital actuality gives, it could change how we take into consideration design and the way we take into consideration fixing issues,” said Mathur. “The spatial immersion and realism that VR can supply could affect how designers strategy design issues, in comparison with when it’s on a pc display screen.”

“I consider VR will make designers take into account that there are specific ranges of complexity {that a} product could profit from and that additive manufacturing could be the way in which to go about it.”

Digital twins, high quality assurance, and upkeep

The usage of digital twins in additive manufacturing is nothing new, with firms already combining digital twins with VR to optimize the method simulation of 3D printed components.

As an illustration, throughout Formnext 2023 Isabelle Hachette, CEO of Swedish software program firm Interspectral, defined how the corporate’s AM Explorer software program allows the creation of multi-channel digital twins. Right here, customers can work together with 3D printed designs and components in a VR or AR atmosphere.

Based on Mathur, the worth of VR right here is determined by what the designer or engineer is hoping to realize from the digital twin. On the one hand, if the digital twin is simply required to supply numerical knowledge, then the worth of VR is restricted.

Nonetheless, in an software the place the person needs to visualise the digital twin, Mathur sees immense worth in utilizing VR. “If the person needs to visualise and alter issues intuitively, and if they need an interplay synonymous with human experiences, then I see a giant potential in having 3D immersion,” said Mathur. “In case you want to have the ability to manipulate the half or enter an atmosphere in a manner that’s not intuitive or attainable on a pc display screen, then VR positively provides worth.”

Mathur believes that digital twins and VR may play a rising position in 3D printer upkeep and buyer help sooner or later. Within the present context of ongoing provide chain challenges, spending cuts, and efforts to reduce CO2 output, the flexibility to diagnose and resolve {hardware} challenges by VR may actually supply vital worth.

“This doesn’t simply need to be VR, however is also blended actuality,” argued Mathur. “As a substitute of paying $600 for a flight ticket for someone to go to the 3D printers, why not deliver them there digitally? Now we have the potential for that to occur, and I believe that’s one thing folks will spend money on.”

The way forward for VR in additive manufacturing

One development Mathur expects throughout the subject of VR and additive manufacturing pertains to the mixing of synthetic intelligence (AI). “My imaginative and prescient for AI is that, if I’ve a query, I can have the AI generate a solution telling me what I needs to be searching for.”

Mathur additionally pointed to generative AI instruments that may create 3D printing geometries primarily based on prompts. While these will not be tethered to VR, Mathur believes that integrating these instruments into an immersive atmosphere could additional improve the 3D design course of.

In the end, Mathur outlined that his dream is to see VR know-how change the way in which that customers design generative buildings and components with additive manufacturing in thoughts. “We’re usually so targeted on what we are able to see on a pc display screen, that we restrict the spatial nature of design,” said Mathur. “What I’m most excited to see is the event of instruments that assist to advance the way in which we take into consideration design.”

What’s extra, Mathur believes that blended actuality could have a giant position to play in the way forward for additive manufacturing, permitting customers to change between ranges of immersion and seamlessly change between a pc display screen and VR or AR.

“I believe blended actuality has massive potential as a result of it feels extra intuitive,” defined Mathur. “Having a platform the place I can immediately navigate between areas which can be miles away from me and proper subsequent to me is a very thrilling chance.”

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture exhibits Jayant Mathur. Photograph through Jayant Mathur.