Vacuum-bagging and tooling material manufacturer Airtech Advanced Materials Group and Caracol have partnered to improve the AM capabilities for large-scale industrial applications.

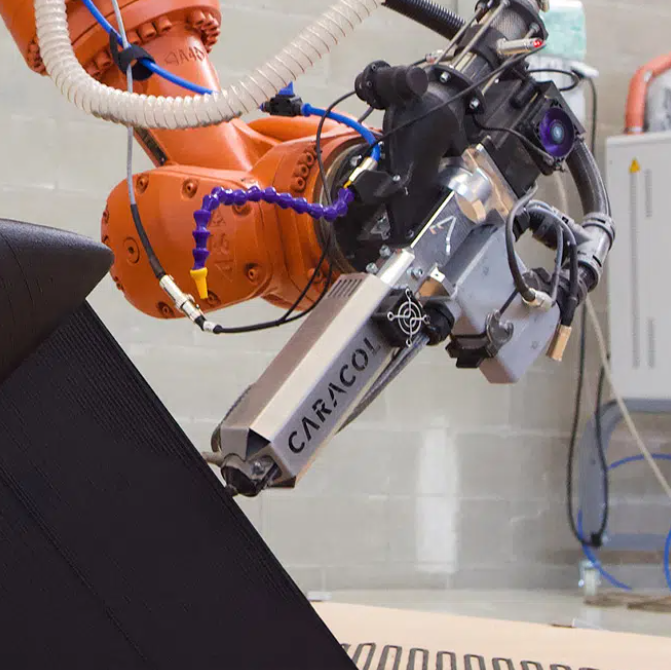

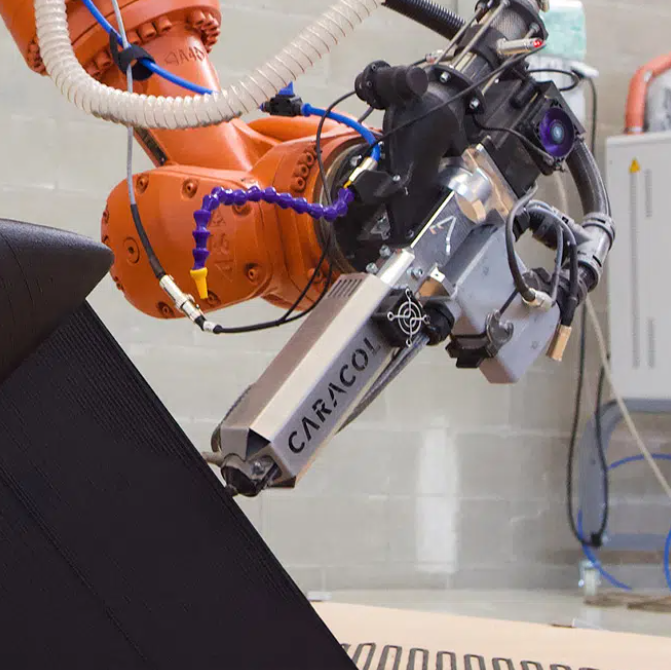

Integrated with hardware, software, and automation, Caracol’s HERON AM platform offers a turnkey solution that optimizes flexibility, process control, and performance. Airtech has qualified its Dahltram Resins for integration with Caracol’s HERON AM large format additive manufacturing platforms globally, supporting Caracol in offering Airtech’s Dahltram resins to its customers worldwide. By doing so, both companies enable manufacturers to efficiently and sustainably meet their production objectives. In addition to its partnership with Airtech, Caracol has also collaborated with CMS SpA, a subsidiary of SCM Group.

“We are excited to collaborate with Caracol to bring our Dahltram® resins to their HERON AM platforms,” said Gregory Haye, Director of Additive Manufacturing at Airtech Advanced Materials Group. “This partnership signifies our commitment to driving innovation in additive manufacturing and providing our customers with cutting-edge solutions that meet their evolving needs.”

Dahltram resins ensure long-lasting tooling applications

Known for their exceptional quality and dependability, Dahltram resins have undergone extensive testing and validation to ensure they work seamlessly with HERON AM platforms. Airtech’s range of Dahltram resins is uniquely compatible with various printing platforms and offers unmatched flexibility for production, along with approvals for end-use materials. Extensive testing, including rigorous thermal cycle testing, pressure leak testing, laser surface scanning, and contact material testing, has produced data confirming the durability of Dahltram tooling resins, capable of enduring more than 500 autoclave cycles without degradation.

With the introduction of Dahltram T-100GF, Airtech ventured into recycled-grade thermoplastic polymer resins for pellet-fed, large-scale 3D printing. According to the company, these are making a substantial contribution, particularly to sustainability efforts. Notably, Dahltram I-350CF played a crucial role in the EmpowerAX project, earning recognition as the winner of the 2024 JEC Innovation Award for Aerospace Processes.

“Working with a partner like Airtech on advanced materials is a key step for us in enabling customers to have an end-to-end manufacturing process that guarantees reliability, quality, and efficiency,” says Violetta Nespolo, Chief Marketing and Strategy Officer at Caracol. “Our end goal is always delivering the highest quality standards and results on our clients’ applications, and we believe that we can drive this only by collaborating with the best partners across the value chain.”

Airtech’s Dahltram resins have been leveraged many times before for various applications. Back in 2022, Airtech collaborated with Brumos Racing to optimize a 700-hp Porsche for the 100th Pikes Peak International Hill Climb. Utilizing custom 3D printed mold tooling made from Dahltram resin, Airtech enhanced the vehicle’s performance with lighter and aerodynamically superior parts. These upgrades, created through advanced technologies, promised increased efficiency and flexibility in design while significantly reducing development time.

In July 2021, Airtech Advanced Materials Group partnered with Titan Robotics to ensure compatibility between Airtech’s Dahltram line of resins and Titan’s machines. As part of their collaboration, the firms worked extensively at Airtech’s headquarters, validating and optimizing the material’s properties and performance when used with Atlas 3D printers.

Caracol expands large format 3D printing expertise with CMS SpA

Through this partnership, Caracol and CMS SpA aim to advance the global large-format 3D printing market by leveraging commercial synergies and technological developments, says the company. The collaboration between Caracol and CMS aims to capitalize on the technical expertise developed on different movement supports, combining robotics with 6+ axes and 5-axis centers. Together, they intend to offer clients the advantages of additive manufacturing for large-scale components.

Partnering with strategic companies in aerospace, automotive, and marine sectors, CMS manufactures machines and systems for processing diverse materials including CNC multi-axis machining centers, thermoforming machines, and waterjet cutting systems. CMS has ventured into the additive manufacturing sector with CMS Kreator, an exclusive large-format AM solution. The company’s offering encompasses hybrid machines combining additive technology with milling, as well as standalone printing machines, leveraging its decade-long experience in composite material processing to deliver high technological value.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows The Heron AM hardware-software robotic system. Photo via Caracol.