Binder jet 3D printer producer voxeljet and Austrian materials recycling firm Parastruct GmbH have performed a proof of idea for using recycled, biogenic, and mineral waste in binder jet 3D printing.

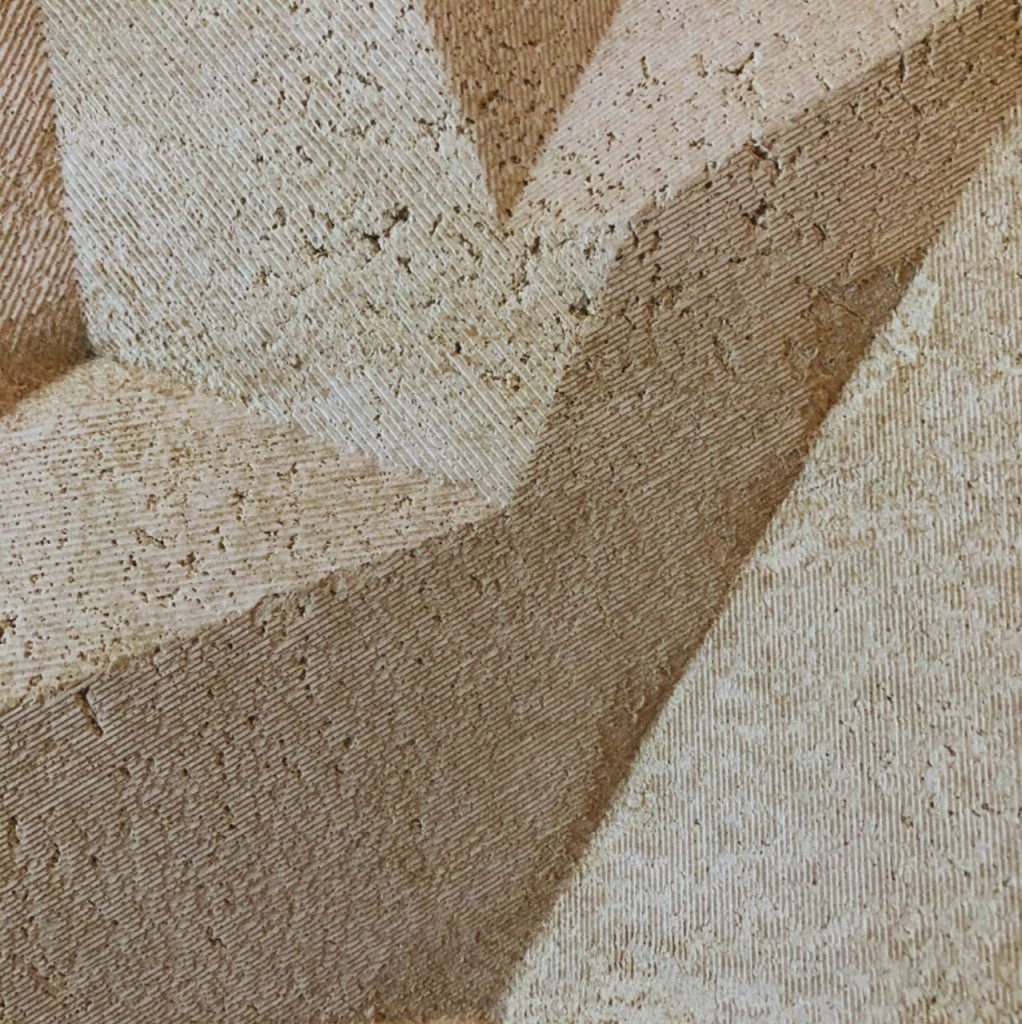

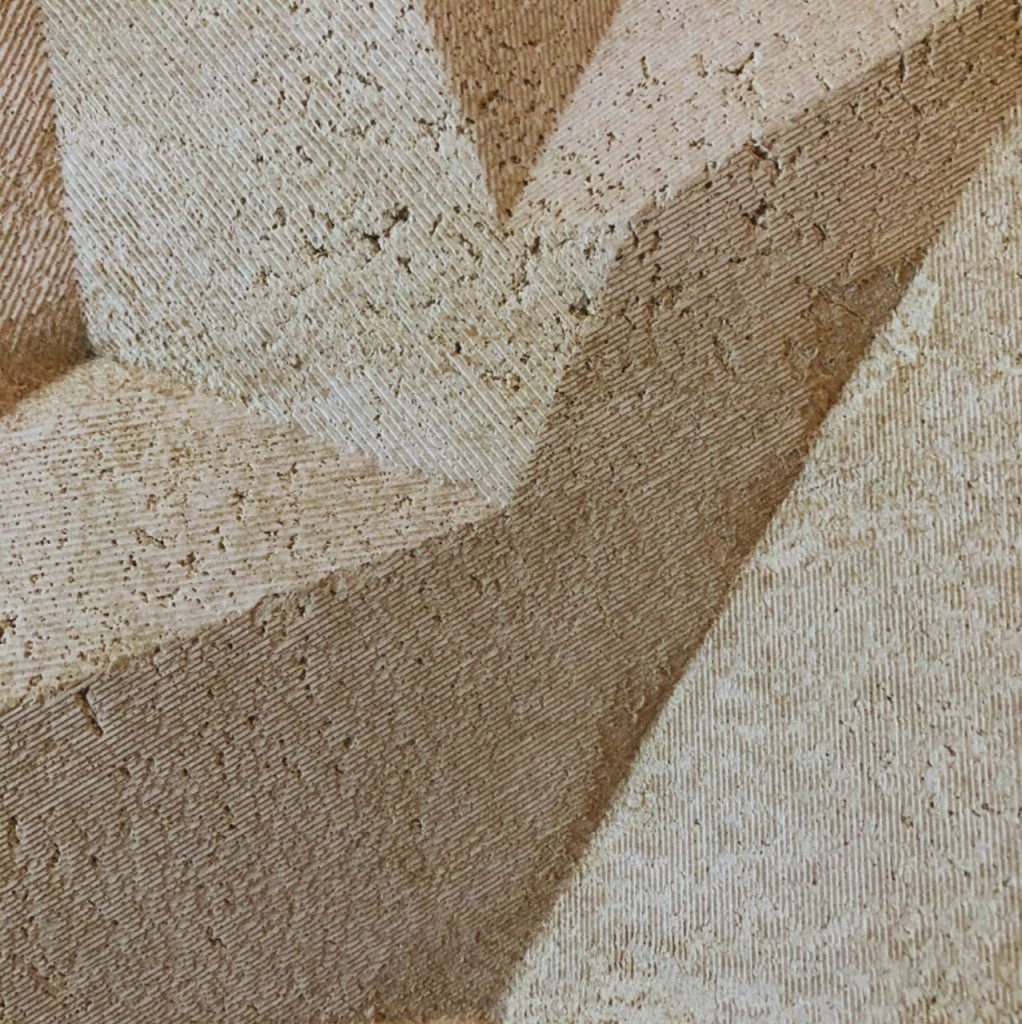

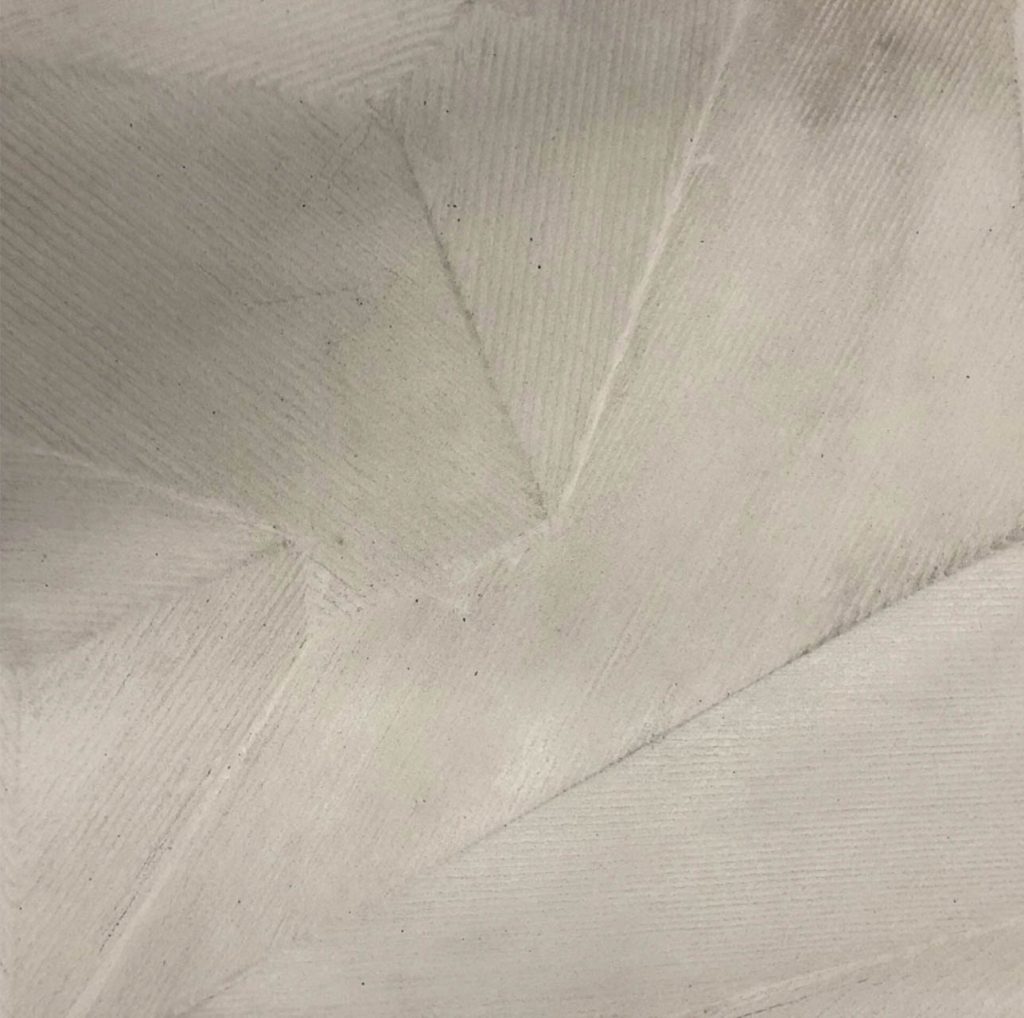

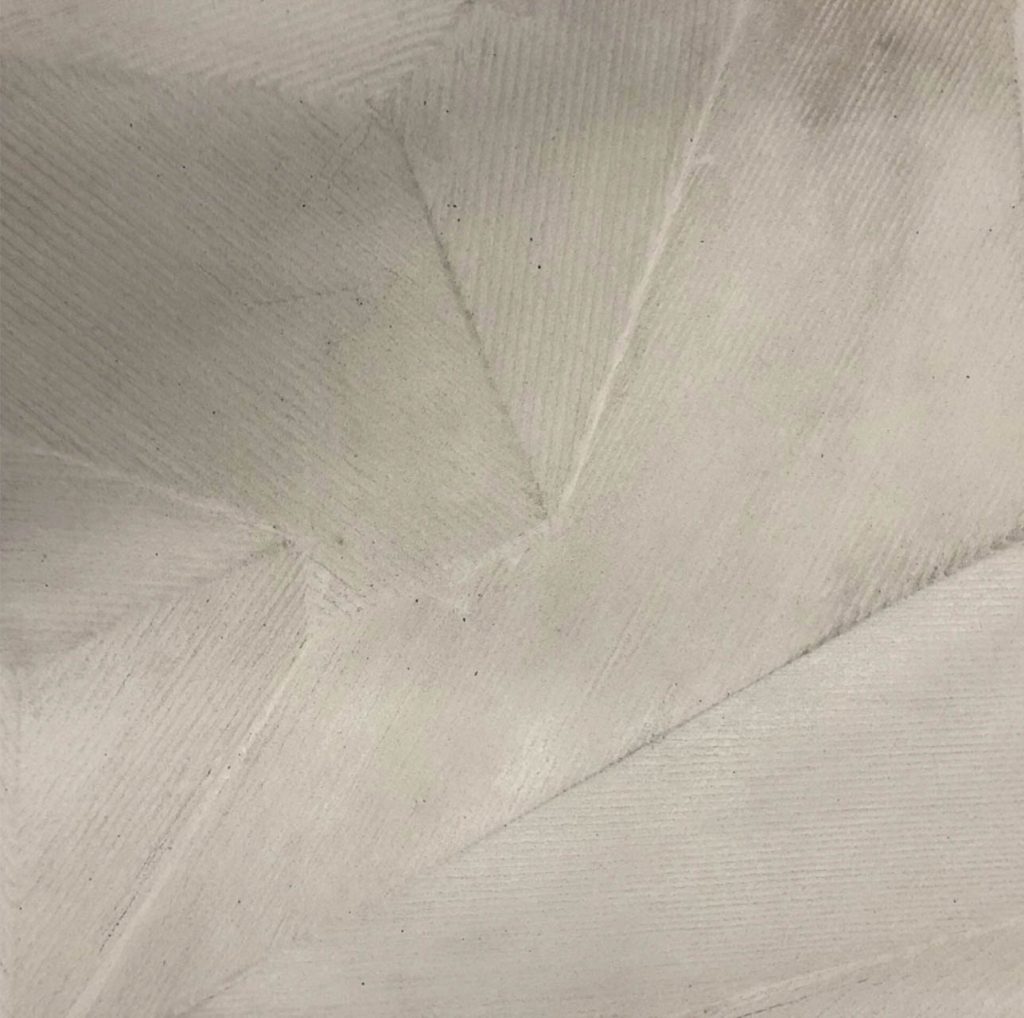

The 3D printability research assessed the voxeljet VX200 3D printer with Parastruct’s Ecomould recycled materials set, which consists of biogenic residue from the development business, and a mineral binder.

Parastruct’s materials and binder choices are totally recyclable, and might reportedly cut back materials consumption by 90%, minimizing disposal prices within the course of.

The 2 corporations will now work to additional develop this expertise inside mildew making, together with the chilly casting of concrete and ceramics and laminating functions. Mould making functions are forecast to develop 7-9% by 2025.

Voxeljet and Parastruct additionally hope to collaborate with events to extend the sustainability of the development business in a future funding undertaking.

Sustainable mildew making with voxeljet and Parastruct

Parastruct’s providing reintroduces unused mineral supplies again into the manufacturing course of by means of 3D printing. These recycled supplies embody development waste and biogenic assets, reminiscent of wooden flour and sawdust.

Rising curiosity and demand for sustainable materials choices are being pushed by rising authorized obligations and buyer necessities as a part of Company Social Accountability (CSR) methods. The implementation of stricter sustainability pointers, such because the EU Inexperienced Deal, has additionally motivated a transfer in the direction of greener additive manufacturing processes.

The Ecomould materials can reportedly assist corporations obtain these sustainability targets. Certainly, Ecomould emits -108.3kg CO2 per 1 m2 of mildew floor, a considerably decrease carbon footprint than conventionally manufactured sand-phenolic resin molds.

In line with voxeljet, 3D printing with Parastruct materials additionally allows corporations to make notable financial savings by eliminating disposal prices. These prices will be as excessive as €750-100 per ton for development waste and €70-180 per ton for wooden. The companions’ recycled 3D printing capabilities also can cut back useful resource expenditure to enhance profitability.

On the finish of the product life cycle, Ecomould-produced molds will be shredded and reused as materials in 3D printing as a part of a round provide chain. This considerably reduces the fabric’s carbon footprint.

In the course of the proof of idea evaluation, voxeljet’s VX200 large-format binder jet 3D printer was utilized at the side of the Euromold materials. Designed for analysis and growth functions, the VX200 encompasses a 9 liter 3D print quantity and might obtain decision of as much as 254 dpi.

The VX200 is just not the one voxeljet 3D printer nicely suited to the recycled Ecomould materials. All voxeljet 3D printers are open supply, with their 3D printing parameters flexibly adaptable to satisfy a variety of fabric units. Furthermore, voxeljet 3D printers provide a variety of construct sizes as excessive as 4 x 2 x 1 m. This reportedly allows simple scaling of Ecomould to bigger, high-production techniques.

Recycling to safe AM provide chains

Within the 2024 3D Printing Business Government Survey, additive manufacturing leaders outlined the 3D printing developments for 2024. Provide chain sustainability and lowering the environmental impression of additive manufacturing had been highlighted as two key developments to look out for this 12 months.

These developments had been additionally pertinent in 2023. Final 12 months, industrial 3D printing supplies developer 6K additive partnered with Surgical Steel Recycling (SMR) to recycle finish of life surgical implants into new titanium powder for 3D printing.

Introduced throughout RAPID + TCT 2023, this collaboration makes use of 6K’s UniMelt production-scale microwave plasma platform to create the powder, which might then be used to 3D print new implants. Leslie Frost, Senior Director of Advertising and marketing at 6K Additive, advised 3D Printing Business that this course of will permit for an “extremely sustainable and round provide chain.”

Elsewhere, North Carolina-based titanium developer IperionX introduced that it will provide Ford with 100% recycled titanium. This partnership is a part of the automotive producer’s purpose to realize carbon neutrality by 2050.

The Scope of Work settlement types a part of an ongoing collaboration between the 2 corporations to design, check, and 3D print titanium parts for Ford Efficiency manufacturing autos. Notably, IperionX’s titanium will be totally recycled on the finish of the product’s life, permitting for a completely round, low-carbon materials provide chain. In line with IperionX, this isn’t potential with different commercially out there titanium manufacturing processes.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of out there roles and kickstart your profession.

Featured picture exhibits voxeljet VX200 binder jet 3D printer. Photograph through voxeljet.