The Supplies Processing Institute is working with Additive Manufacturing Options and AMFG to develop a predictive materials reuse administration instrument that leans on synthetic intelligence as a part of an Innovate UK-funded analysis undertaking.

Often called SMART-APP, the instrument will introduce sensible predictive fashions for useful resource effectivity and waste discount. If the 600,000 GBP analysis collaboration is profitable, SMART-APP will probably be made commercially obtainable to customers of laser powder mattress fusion 3D printing expertise.

The SMART-APP undertaking goals to foretell the standard change of the powder after every course of, proposing different course of parameters on used powder to increase its lifespan with a minimal or an in-specification affect on product high quality. It would place a give attention to metallic additive manufacturing, which has been deemed by the companions to not but be cost-effective because of a growth hole within the degree of powder waste and size of processing time.

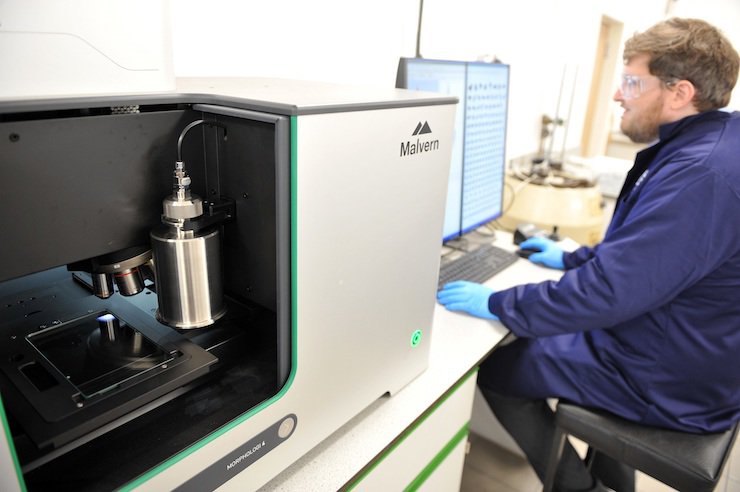

To handle such points, the analysis will function ‘state-of-the-art supplies characterisation and mechanical testing’, whereas additionally investigating shelf life and the processability envelope of environmentally affected widespread chrome steel, titanium and superalloy base feedstock. The ensuing outputs will probably be fed into a complicated database linking powder enter properties towards AM half efficiency to offer a predictive instrument that will probably be obtainable for business to make use of.

Nick Parry, Industrial Digitalisation Group Supervisor on the Teesside-based Supplies Processing Institute, commented: “SMART-APP is the subsequent logical step to proceed the work the Institute has already undertaken in powder characterisation. This predictive instrument will develop and allow world class manufacturing of AM parts, with sensible options for useful resource effectivity and offering longer use of supplies feedstock and decreasing wastage.”

Rob Higham, CEO of Additive Manufacturing Options, added: “AMS is delighted to have the help of Innovate UK to proceed growing our portfolio of world main powder and AM course of optimisation functionality. This marks our first step in the direction of a ground-breaking strategy for dynamic supplies administration. The potential of the AM course of stays a possible in many individuals’s eyes. It might be realised with the event of a flexible and sensible predictive instrument for monitoring powder high quality after every reuse.”

Alexander Grimmer, Technical Marketing consultant at London-headquartered AMFG, supplied: “This initiative goals to rework additive manufacturing in the direction of extra resource-efficient strategies. SMART-APP goals to instil belief within the additive manufacturing realm by forecasting powder high quality and recommending processes to revive desired powder properties for reuse. AMFG eagerly anticipates contributing to a cutting-edge materials administration system on this undertaking, poised to ship substantial environmental and financial advantages to the business. This endeavour is about to expedite the widespread adoption of additive manufacturing.”