ETH Zurich spin-out Scrona AG and Avantama, a producer of specialty supplies for printed electronics, have efficiently processed high-performance quantum dot (QD) ink utilizing Scrona’s electrohydrodynamic (EHD) inkjet 3D printing know-how.

In accordance with Scrona, EHD 3D printing allows fabrication at a lot smaller resolutions than typical inkjet 3D printing, making it effectively suited to the manufacturing of semiconductors and micro-displays. Crona EHD 3D printing can obtain resolutions under 1µm.

Avantama’s perovskite QD 3D printing inks are effectively suited to Scrona’s micro-3D printing course of, possessing the best absorption coefficient amongst QDs. This permits for 3D printing of pixels with wonderful resolutions and good optical density, considerably lowering manufacturing time.

The businesses declare that this collaboration will allow environment friendly and cost-effective manufacturing of 3D printed MicroLED shows with elevated shade purity and brightness.

“We proceed to search out new functions of EHD that can meet the calls for of the trade by providing an additive, fully waste-free course of with larger decision capabilities than lithography patterning,” commented Dr Patrick Galliker, co-founder and CEO of Scrona.

“Whereas typical inkjet printheads require inks of low viscosity, Scrona has already demonstrated printing inks 1,000 occasions what they will course of, paving the way in which for a way more environment friendly era of MicroLED shows.”

Scrona sub-micron 3D printing with Avantama materials

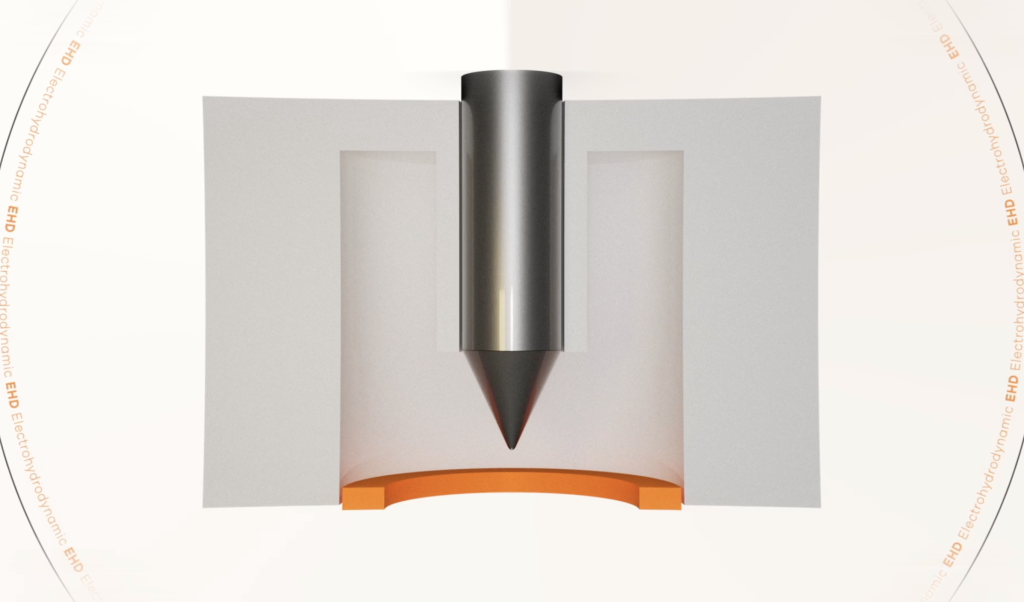

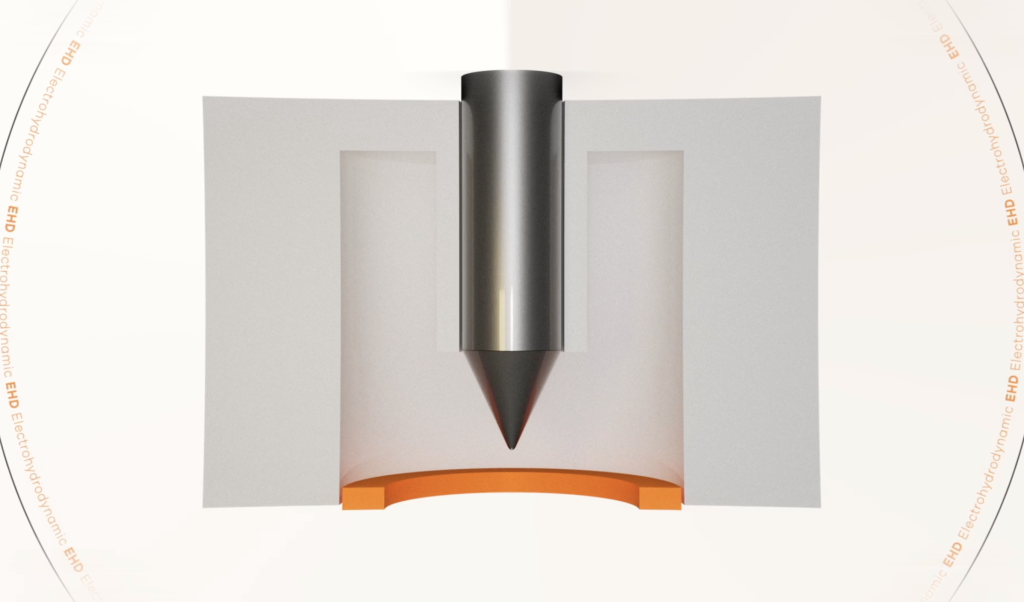

Scrona’s EHD electrostatic multi-nozzle 3D printing know-how is alleged to supply important benefits over typical inkjet 3D printing for the manufacturing of multi-material, practical digital merchandise.

The corporate says that the nozzle-based jetting strategy of present inkjet know-how produces slender droplets with excessive fluidic content material, stopping the manufacturing of ultra-high decision elements. Not like typical inkjet 3D printing which extrudes materials by pushing droplets from a nozzle, Scrona’s EHD know-how makes use of electrostatic forces to tug the fabric out.

These pulling forces are centered solely on the tip of microfabricated nozzles, permitting extremely small droplets to ejected, accelerated, and guided downwards. Droplet dimension might be managed by the utilized voltages, enabling the manufacturing of droplets which might be one order of magnitude smaller than the nozzle.

In accordance with Scrona, this extrusion course of allows the jetting of thicker, extra concentrated liquid that may kind objects with a lot finer resolutions than typical inkjet 3D printing.

The event of Scrona’s proprietary inkjet 3D printing know-how was aided by a 2022 Collection A funding spherical, by which the businesses raised $9.6 million. The corporate obtained monetary backing from AM Ventures, TRUMPF Enterprise, Verve Ventures and Manz Administration Consulting and Funding.

This funding has enabled the corporate to “speed up the industrialization” of its know-how, bringing it to market by means of this collaboration with Avantama.

Avantama’s perovskite-based materials providing possesses larger weight-based absorption than some other QDs. This interprets to very excessive OD thickness values, splendid for Scrona’s high-resolution extrusion course of. The inherent defect-tolerance of perovskite allows this notable property, which means {that a} passivating shell isn’t required to realize high-emission quantum yields.

This makes Avantama materials, when used together with Scrona inkjet 3D printing, effectively suited to the manufacturing of MicroLED parts.

“Standard inkjet printing isn’t a viable possibility for rising MicroLED shows as a result of they use a lot smaller pixels than QD-OLED shows,” acknowledged Dr Norman Lüchinger, co-founder and CTO at Avantama.

“By partnering with Scrona, we now have been in a position to show that an OD better than 1 might be obtained with a perovskite QD layer thickness under 2μm. This may scale back the printhead nozzle depend by an element of 5 and ship a skinny QD layer that improves the general effectivity and manufacturing takt time of MicroLED show know-how.”

Developments in micro-3D printing

Scrona’s EHD 3D printer isn’t the primary designed for the fabrication of micro-scale parts akin to MicroLED’s. Again in 2022, Desktop 3D printer producer Anycubic partnered with show panel specialist Jade Fowl Show (JBD) to develop a consumer-grade MicroLED 3D printer.

Referred to as the J1 MicroLED, this 3D printer featured a UV MicroLED show and adjustable 0.3CC mild engine, enabling it to provide elements with particulars as small as 10µm. As such, the system was marketed as the primary 3D printer of its variety to allow “low-energy consumption and a protracted lifespan at a aggressive worth.” Measuring simply 175mm in peak, the J1 is extremely compact, permitting it to be simply transported and deployed for on-demand MicroLED 3D printing.

It was introduced final yr that Austria-based high-precision optical gadget developer In-Imaginative and prescient had collaborated with Professor Tapajyoti Das Gupta of the Indian Institute of Science-Bangalore to develop a sub-micron 3D printer.

Working with Mumbai-based 3D printer producer J Group Robotics, the companions have constructed the 3D printer which might produce versatile, stretchable photonic units. It’s hoped that this new 3D printer will decrease the price of manufacturing for nano-scale, high-performance optical units, disrupting the semiconductor trade within the course of.

Das Gupta expects the 3D printer to be producing its first sub-micron optical parts in spring 2024.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the newest 3D printing information. You can too observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals a Scrona inkjet 3D printing nozzle. Picture through Scrona.