Researchers from the College of Colorado Boulder have developed a novel course of for figuring out materials properties in inkjet additive manufacturing.

Referred to as a “pantone for properties” by examine co-authors Robert MacCurdy and Lawrence Smith, these findings define how multi-material inkjet 3D printing can create particular materials properties by combining totally different resin supplies.

Much like how a selected colour could be created by mixing totally different major colours, these findings define how repeatable 3D printed materials properties could be realized by mixing three “major” supplies. These supplies embrace a tender elastomer, a inflexible plastic, and liquid constituents.

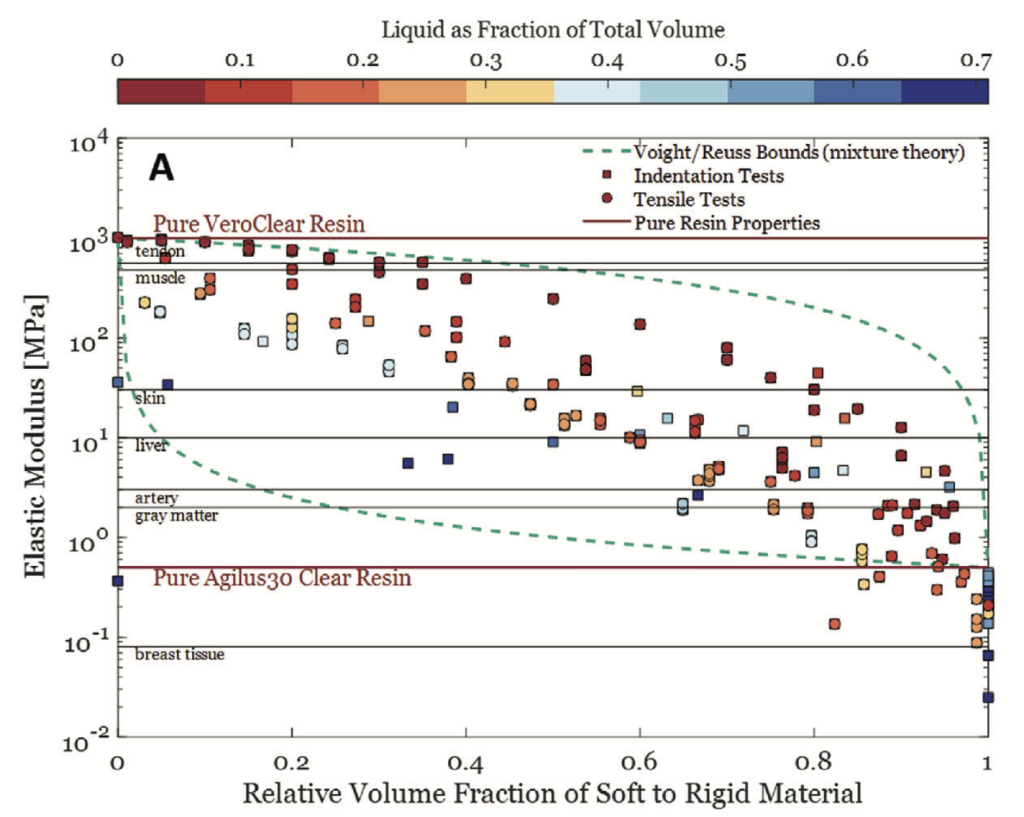

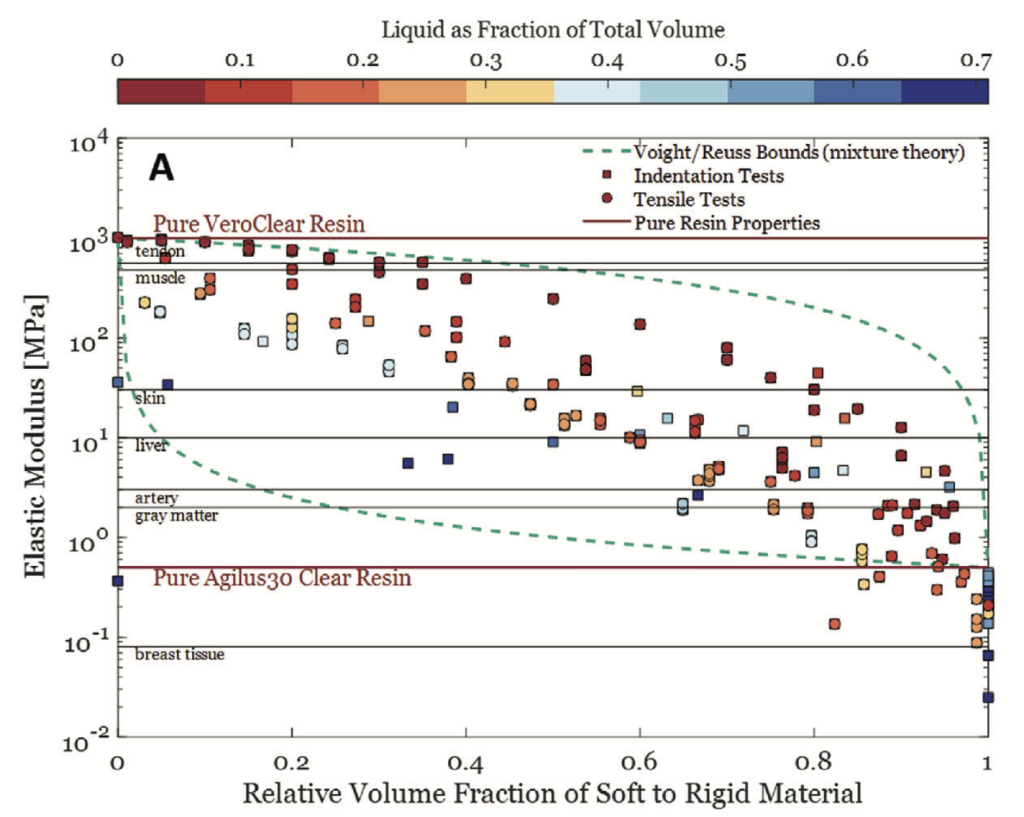

Within the examine, the researchers used customized software program to design a whole bunch of digital composite materials samples. As soon as 3D printed, the mechanical properties of the samples have been examined and characterised. Analytical mappings evaluating composite substances and mechanical properties have been then created, enabling “inverse materials design.”

This course of reverses the normal materials choice processes. Usually, engineers seek for an appropriate materials which possesses desired materials properties, after which create a design based mostly on the fabric. As an alternative, the brand new methodology permits a desired set of fabric properties to be specified first for an element, which is then 3D printed.

The authors declare this analysis is the primary to characterize digital materials composites produced from three inkjet supplies with totally different mechanical properties. Earlier research have solely assessed two-material composites, which “fall in need of mechanical realism.”

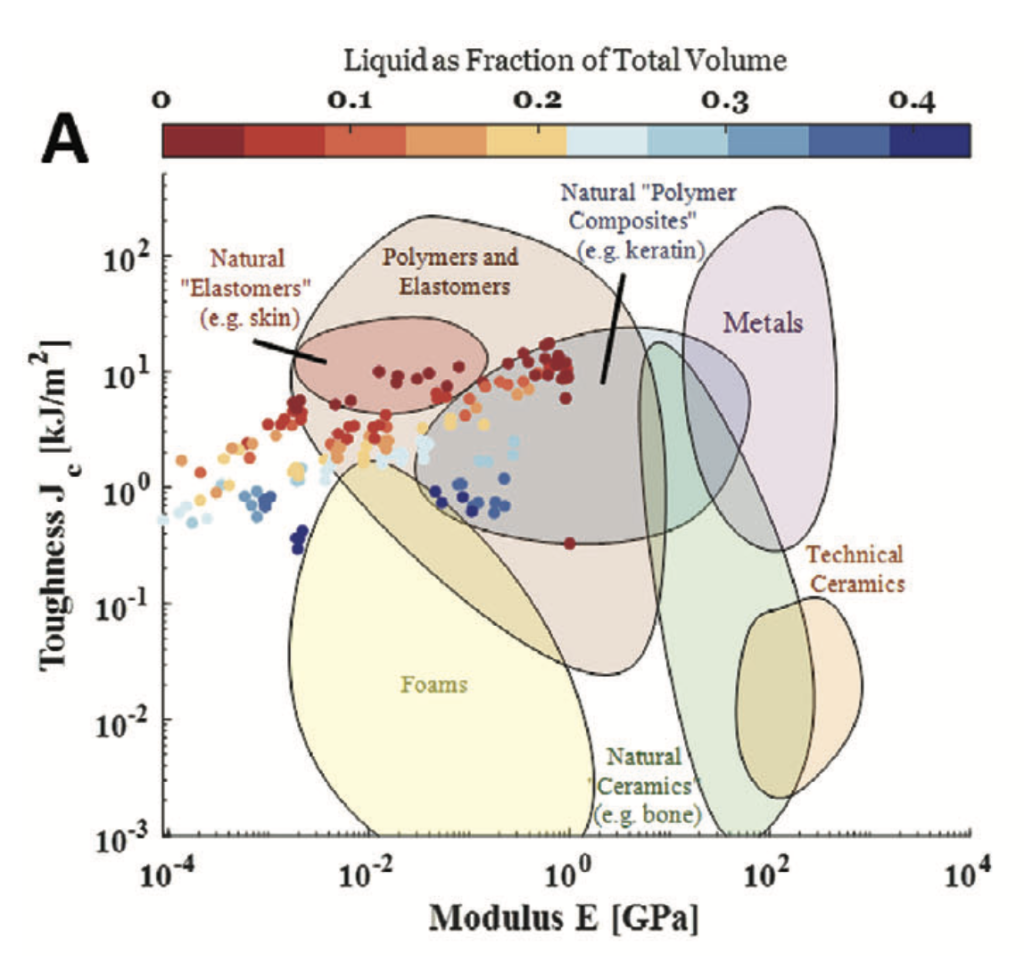

Potential purposes for this course of are numerous. The researchers spotlight 3D printing mechanically-plausible artificial organic tissue as being one potential use-case. Leveraging the inverse materials design method, customers can design and 3D print supplies with any mixture of stiffness and toughness wanted to precisely mimic organic tissue.

The examine, titled “Digital Multiphase Composites by way of Additive Manufacturing,” has been printed in Superior Supplies.

A pantone for 3D printed materials properties

Multi-material inkjet 3D printers jet droplets of photopolymer resins which might be then cured by a UV gentle supply, forming 3D objects.

The Agilus and Vero inkjet 3D printing resins from 3D printer producer Stratasys possess totally different properties after curing. Agilus turns into a troublesome and versatile elastomer materials, whereas Vero types a inflexible plastic. These two supplies could be mixed in numerous ratios to create composite supplies with totally different properties. Nevertheless, the property prospects of those combos are restricted.

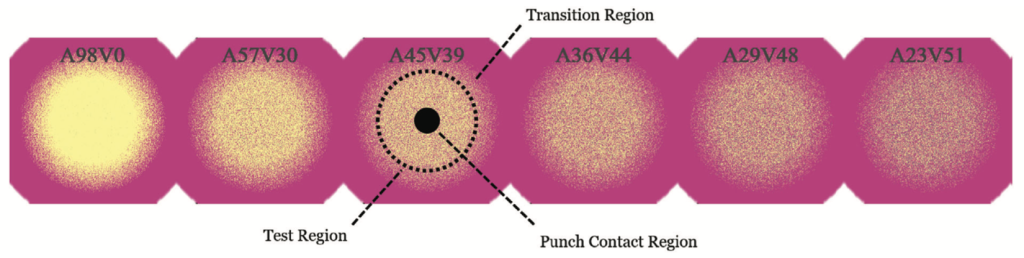

To attain better material-property freedom, the College of Colorado researchers added a 3rd, liquid-based materials into the composite design course of. Through the analysis, 188 exams have been carried out on 110 distinctive composite materials formulations.

By means of experimental commentary and validation utilizing 3D printed components, the researchers confirmed that it’s attainable to independently dictate mechanical properties like elasticity and toughness by combining the three base-materials.

Mechanical testing was carried out utilizing a punch check. 3D printed check samples have been uncovered to a stainless-steel dowel lowered via the “punch area.” The staff then recorded the indentation distance and drive of the samples, with the check terminating when the fabric failed.

The outcomes of this testing highlighted that elastic modulus and toughness properties are decoupled, and could be independently specified throughout 3D printing. What’s extra, the examine concluded that any two materials properties could be decoupled utilizing this method. That is enabled by the addition of the third liquid-based materials into the composite design course of.

The researchers additionally demonstrated inverse design of 3D printed objects with prescribed properties. This was achieved by creating mappings between compound materials substances on the microscale, and macroscale materials properties.

Utilizing analytical modeling and mathematical equations, the researchers efficiently used these mappings to precisely estimate the mechanical properties of quite a lot of inkjet composites that mix elastomer, inflexible, and liquid resins.

In the end, the researchers argue that these findings maintain vital potential inside medical purposes.

With present strategies, researchers have struggled to realize correct materials properties that mirror organic tissues. The findings of this examine are mentioned to allow the stiffness and toughness of a fabric to be concurrently and independently altered. This enables researchers, designers, and medical practitioners to 3D print real looking and mechanically convincing artificial organic tissue.

Analysis into inkjet 3D printing

MacCurdy and Lawrence’s analysis just isn’t the primary to discover the potential provided by multi-material inkjet 3D printing for medical purposes. Researchers from the MIT Media Lab, Harvard College’s Wyss Institute, and the Dana-Farber Most cancers Institute developed a way to 3D print hybrid residing supplies.

Referred to as the Hybrid Residing Materials (HLM) fabrication platform, the staff used multi-material inkjet 3D printing and customised materials recipes to mix resins and chemical indicators. These indicators activate responses in biologically engineered microbes, providing potential for medical units with therapeutic brokers.

On this analysis, an appropriate assist resin was mixed with a structural resin materials to 3D print components that grow to be absorbent and retain chemical indicators to manage the conduct of residing organisms. The HLM platform can leverage three to seven totally different resins with totally different properties, combined in a spread of proportions with artificial organic materials.

Elsewhere, a staff from Martin Luther College Halle-Wittenberg developed a hybrid additive manufacturing course of that mixes extrusion and inkjet 3D printing.

This method permits liquid inks to be built-in straight into stable materials matrices. One key utility of that is the combination of lively medical substances into 3D printed drug supply units on the preliminary manufacturing stage.

The staff additionally recognized purposes in structural engineering. Right here, fluorescent liquids could be housed in stable structural elements, permitting customers to visible monitor cracks.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You may as well observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture reveals the experimental outcomes, with colour indicating the amount fraction fluid.