Researchers from the Massachusetts Institute of Know-how (MIT) have printed a brand new examine demonstrating the advantages of Liquid Steel Printing (LMP) for large-scale building and structure purposes.

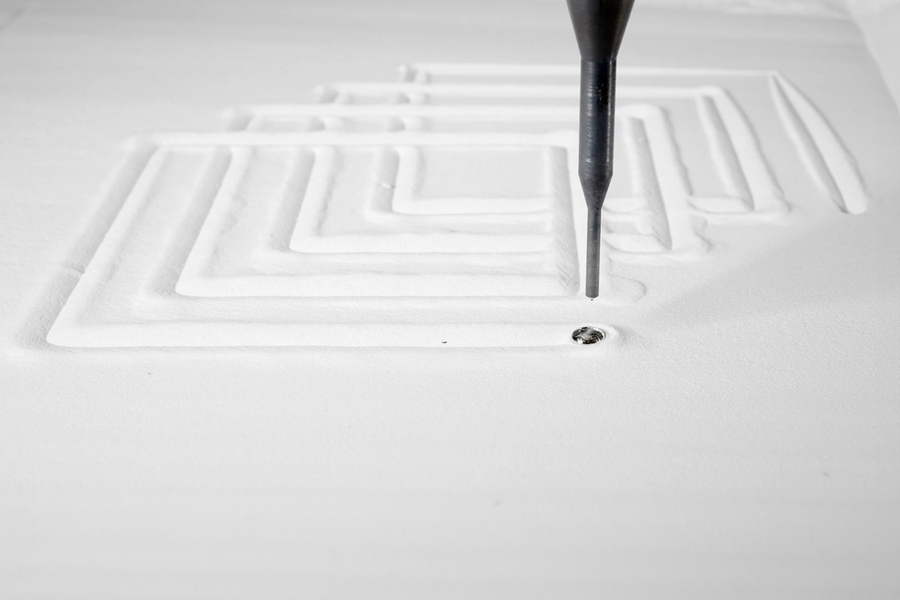

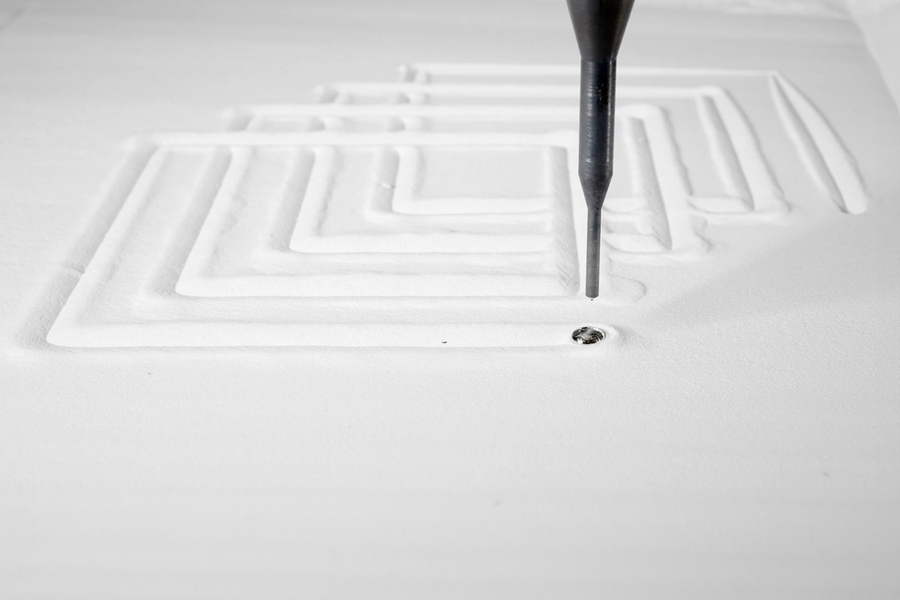

The crew’s LMP 3D printing strategy deposits molten aluminum onto a mattress of small glass beads, with the aluminum shortly hardening right into a 3D construction. This course of sacrifices floor decision and precision for pace. LMP reportedly fabricates 3D printed steel constructions 10 occasions sooner and at decrease prices than different steel additive manufacturing strategies.

Whereas LMP isn’t a brand new know-how, the researchers state that this examine is the primary to exhibit its worth in quickly fabricating large-scale components for structure and building purposes.

The examine, printed by the Affiliation for Pc Aided Design in Structure (ACADIA), additionally argues that LMP presents sustainability benefits in large-format steel 3D printing. The MIT crew factors to LMP as being effectively suited to speedy prototyping and manufacturing utilizing recycled or scrap steel.

The researchers 3D printed a spread of aluminum constructions to assist their speculation, together with frames for tables and chairs. The examine highlights that parts made with LMP might be mixed with further supplies and post-processing steps to create practical furnishings.

“It is a fully totally different path in how we take into consideration steel manufacturing that has some large benefits. It has downsides, too. However most of our constructed world — the issues round us like tables, chairs, and buildings — doesn’t want extraordinarily excessive decision,” commented Skylar Tibbits, a senior creator of the examine and affiliate professor at MIT’s Division of Structure. “Velocity and scale, and likewise repeatability and power consumption, are all vital metrics.”

LMP quickens large-scale steel AM

Wire Arc Additive Manufacturing (WAAM) is an current steel 3D printing know-how that’s distinguished within the building and structure sector. Like LMP, WAAM can shortly fabricate massive, low-resolution constructions. Nonetheless, WAAM-produced components might be vulnerable to warping and cracking as remelting is usually required throughout the 3D printing course of.

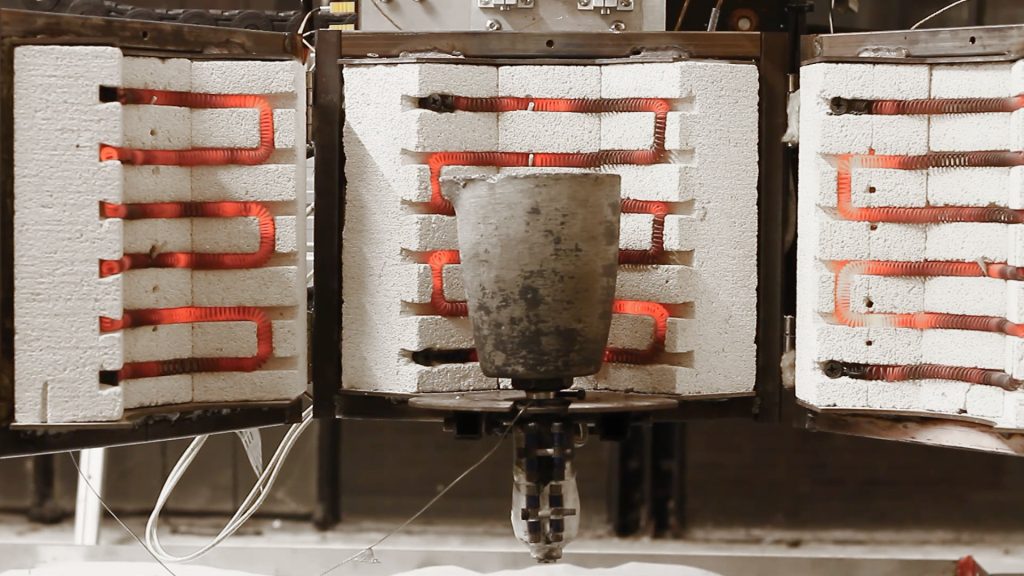

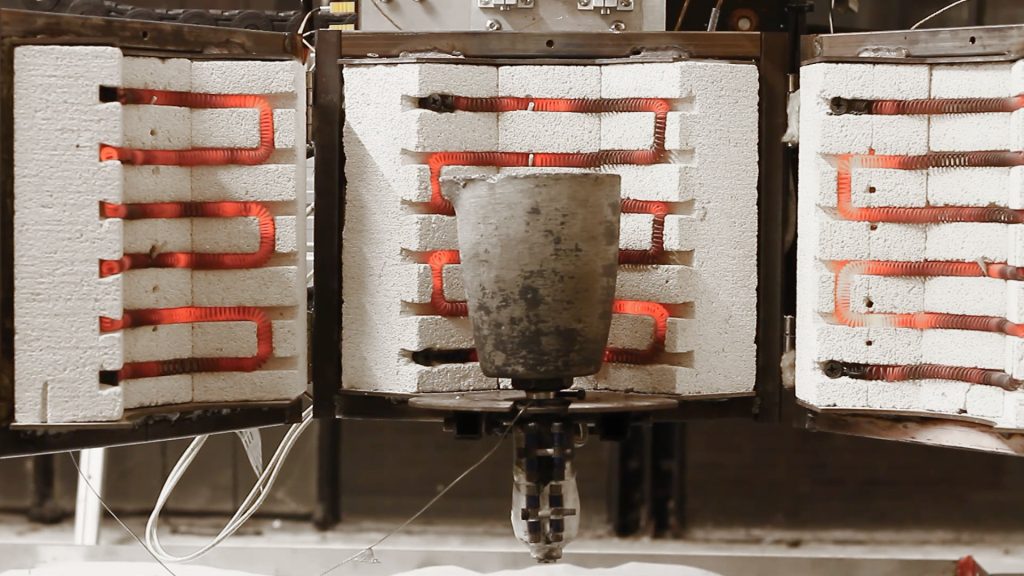

LMP reportedly overcomes these challenges, because the steel stays molten all through the 3D printing course of. The MIT crew’s LMP is optimized to be used with aluminum. The 3D printer extrudes molten aluminum by way of a ceramic nozzle at excessive speeds right into a mattress of glass beds. This course of can reportedly 3D print large-scale steel components in seconds, with the molten aluminum cooling and hardening in a number of minutes.

Throughout this course of aluminum, chosen for its reputation in building and the convenience at which it may be recycled, is heated to 700℃ in an electrical furnace. After being held at excessive temperature in a graphite crucible the steel, now molten, is gravity-fed by way of the nozzle.

Because the molten materials is injected immediately right into a granular substance, no helps are required throughout LMP 3D printing, permitting large-scale constructions to be shortly and simply fabricated.

Throughout 3D printing, the LMP nozzle is pushed into the glass bead powder, that means that customers can’t watch the molten aluminum be deposited. As such, the crew developed a numerical mannequin that simulates the extrusion course of, estimating the quantity of fabric deposited at any given time.

Within the examine, the researchers used their LMP to quickly produce steel furnishings frames with variable thicknesses. These frames have been sturdy sufficient to resist machining processes corresponding to milling and boring. Combining LMP with these post-processing strategies, the MIT crew fabricated full-scale 3D printed tables and chairs.

The crew concluded that LMP holds important potential within the building and structure industries each as a instrument for prototyping, and as a type of speedy, low-cost, large-scale manufacturing.

Seeking to the long run, the crew will proceed to iterate its LMP know-how to allow nozzle heating, which might assist to stop clogging. The researchers additionally hope to attain higher management over the circulate of molten materials.

In the end, it’s hoped that MIT’s LMP 3D printer might be made extra accessible to permit customers to simply 3D print large-scale components from recycled steel.

“If we may make this machine one thing that folks may truly use to soften down recycled aluminum and print components, that will be a game-changer in steel manufacturing,” defined Tibbits. “Proper now, it’s not dependable sufficient to do this, however that’s the aim.”

Developments in Liquid Steel Printing

Though the primary to exhibit potential in large-scale steel additive manufacturing purposes, the MIT researchers aren’t the primary to leverage LMP 3D printing.

Again in 2018, researchers at Oregon State College (OSU) harnessed Liquid Steel Printing to manufacture small and versatile 3D printed electrical circuits. Combining a liquid steel alloy with nickel, the crew efficiently created a conductive steel paste that was 3D printed immediately onto a versatile floor, creating two full circuits that overlapped with out touching.

Extra just lately, in 2022 Manufacturing system and machine instrument developer GROB-WERKE (GROB) entered the 3D printer market with the launch of its GMP300 LMP 3D printer. This method was designed to allow speedy manufacturing of near-net-shape components from steel wire feedstock in a cost-effective, material-efficient course of.

Marketed as providing the next build-up fee than Powder Mattress Fusion (PBF) and higher decision than Directed Power Deposition (DED), the GMP300 is focused in direction of purposes within the metalworking sector. Possessing a 300 x 300 x 300 mm³ construct quantity, this LPM 3D printer incorporates three-axis kinematics, a high axis pace of 30m/min, and a construct chamber that operates beneath an inert environment.

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. You too can observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture exhibits the LMP 3D printer’s nozzle heating meeting. Picture by Self Meeting Lab.