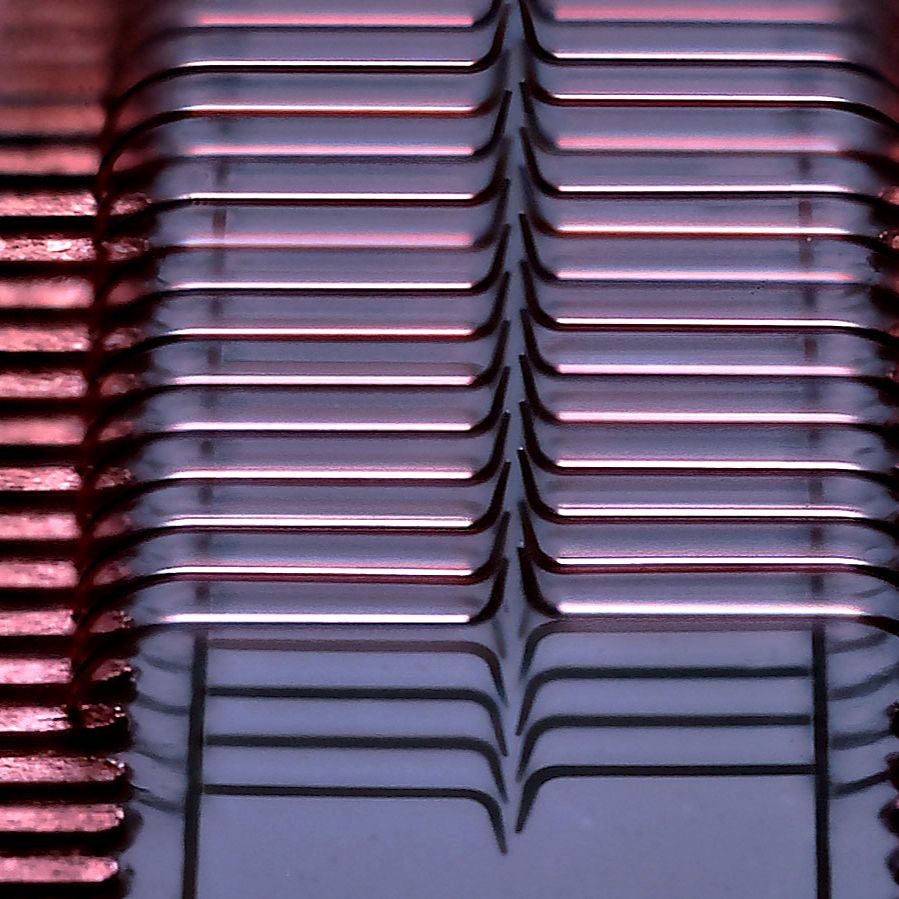

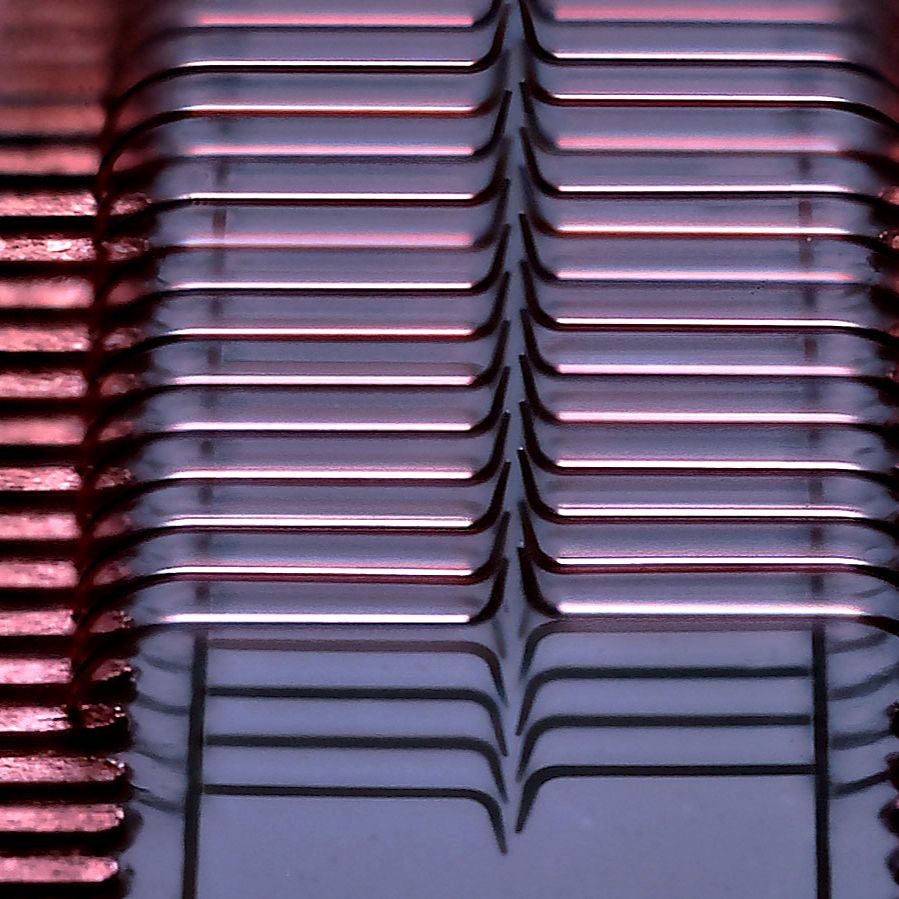

Switzerland-based micro 3D printing firm Exaddon has developed the world’s first 3D microprinted probes able to fine-pitch probing at sub-20 µm pitch. Wonderful-pitch probe testing is a particularly complicated and exact course of used to check semiconductor dies.

Optimized for semiconductor wafer testing, Exaddon’s excessive conductivity probes are 3D printed straight onto customizable and exchangeable area transformers. This reduces complexity, price, and the variety of required part layers.

Exaddon claims that its sub-20 µm capabilities provide vital advantages for the semiconductor business. Testing at finer pitches allows a larger lively die space, which will increase yield and reduces chip price, slicing shopper product prices within the course of. Furthermore, the corporate’s template-free micro 3D printing course of is very customizable and able to fabricating freestanding buildings with excessive side ratios.

“The distinctive capabilities of Exaddon’s μ3D printing know-how, made doable by native electrodeposition of pure steel, gives an unprecedented route towards efficiently accessing and testing at sub-20 μm pitch,” Exaddion said in a press launch.

“Any software which requires effective pitch probing under the present pitch restrict stands to profit from this distinctive strategy.”

Exaddon 3D microprinting enhances fine-pitch probing

Based in 2019 as a spin-off from Swiss micro 3D printing firm Cytosurge, Exaddon specializes within the additive manufacturing of micro steel components. Since its launch, the corporate has established itself as a key supplier of 3D printing know-how for tutorial analysis initiatives all over the world.

The corporate’s micro 3D printing capabilities, developed over the previous two years, search to fulfill demand within the $500 billion semiconductor market. Semiconductor producers depend on probe testing of excessive efficiency dies to make sure that solely Recognized Good Dies (KDG) make it into their remaining semiconductor parts.

In line with Exaddon, probe testing at present struggles to attain pitches under 40 µm. That is stated to restrict chip design and prohibit the flexibility of firms to fulfill shopper demand. For example, regardless of the 80% CAGR and multi-billion greenback valuation of the microLED market, LED testing is at present restricted to a resource- and time-consuming two-probe strategy.

These challenges are overcome by Exaddon’s micro 3D printing know-how, which may fabricate prime quality steel parts measuring lower than 20 µm. The Zurich-based firm has efficiently demonstrated its fine-pitch probe capabilities on µLEDs.

The corporate’s microLED check array is 3D printed straight on pre-patterned traces with a sub 20 µm pitch. This demonstrator array possesses 128 probes, with a minimal pitch of 18.5 µm within the X-axis, 9.5 µm within the Y-axis, and ±2 μm for the Z-planetary. Exaddon’s probe array, which is round 10% the dimensions of different firms’ probe arrays, reportedly provides microLED testers a 64x enhance in effectivity.

What’s extra, Exadden’s template-free 3D printing course of is very customizable, and excels at fabricating excessive side ratio, freestanding buildings similar to coils and lattices. 3D printing straight onto the area transformer simplifies probe card development, eliminating course of steps and parts that might in any other case be required. This reduces prices and complexities related to probe manufacturing.

Sooner or later, the corporate plans to extend probe rely in its μLED arrays and full WAT (water acceptance check) and CIS (CMOS Picture Sensor) probe testing.

Developments in micro 3D printing

Micro 3D printing has been acknowledged by various firms as providing potential throughout the growth and manufacturing {of electrical} gadgets.

Final 12 months, Austria-based high-precision optical gadget developer In-Imaginative and prescient introduced a collaboration with Professor Tapajyoti Das Gupta of the Indian Institute of Science-Bangalore to develop a brand new sub-micron 3D printer. Working with Mumbai-based 3D printer producer J Group Robotics, the companions intention to construct a 3D printer able to fabricating nano-scale photonic gadgets which are versatile and stretchable.

Sometimes, nano-scale, high-performance optical gadgets are produced in a multi-step, layered 2D lithography course of. That is expensive and gives restricted scalability, requiring the usage of a number of machines in a cleanroom facility.

The staff hopes that its new micro 3D printer will speed up and decrease the price of manufacturing, disrupting the semiconductor business within the course of. The primary sub-micron optical parts are anticipated to be 3D printed in spring 2024.

Elsewhere, Microfabrication start-up Horizon Microtechnologies gives its personal proprietary microscale 3D printing know-how. The corporate’s template-based micro-additive manufacturing (micro-AM) course of permits customers to provide conductive components with micrometer-level precision.

This micro 3D printing know-how has been designed to supply larger manufacturing versatility within the manufacturing of electrodes, electrical contact pins, microfluidic gadgets, MEMS, and optical packaging.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the newest 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits a pc render of Exaddon’s template-free 3D print course of. Picture by way of Exaddon.