Researchers from the Massachusetts Institute of Expertise (MIT) have developed a novel warmth remedy methodology which strengthens 3D printed metals.

The brand new course of alters the microscopic buildings of the 3D printed materials, enabling the manufacturing of parts which possess excessive sturdiness and thermal shock resistance.

This course of reportedly unlocks new prospects in 3D printing high-performance blades and vanes for jet engines and fuel generators, permitting for novel designs which cut back gasoline consumption and improve power effectivity.

Developed utilizing AM IN738LC, an additively manufactured tremendous alloy, this warmth remedy course of replaces the as-printed materials’s high quality grain inner construction with extra coarse columnar grains.

Current post-processing therapies comparable to scorching isostatic urgent (HIP) may also be used to create enhanced steel buildings with bigger grains and condensed pores. Nonetheless, the researchers declare that such processes can nonetheless end in metals that deform beneath persistent mechanical stress and excessive temperature, in any other case often known as creep. The supplies’ tendency to creep is minimized via the MIT workforce’s novel post-processing remedy.

The examine, titled Directional recrystallization of an additively manufactured Ni-base superalloy, was revealed within the journal Additive Manufacturing.

“Within the close to future, we envision fuel turbine producers will print their blades and vanes at large-scale additive manufacturing vegetation, then post-process them utilizing our warmth remedy,” acknowledged Zachary Cordero, the Boeing Profession Growth Professor in Aeronautics and Astronautics at MIT.

“3D-printing will allow new cooling architectures that may enhance the thermal effectivity of a turbine, in order that it produces the identical quantity of energy whereas burning much less gasoline and in the end emits much less carbon dioxide.”

Anti-creep warmth remedy

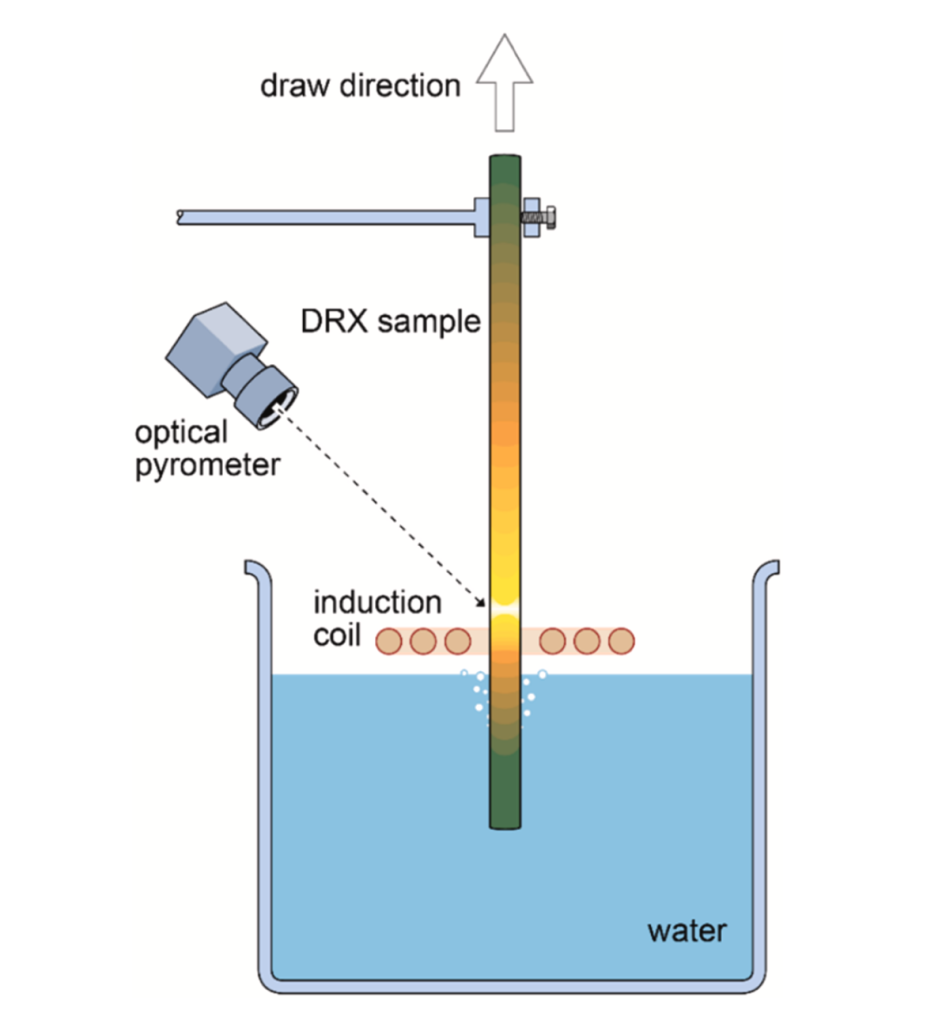

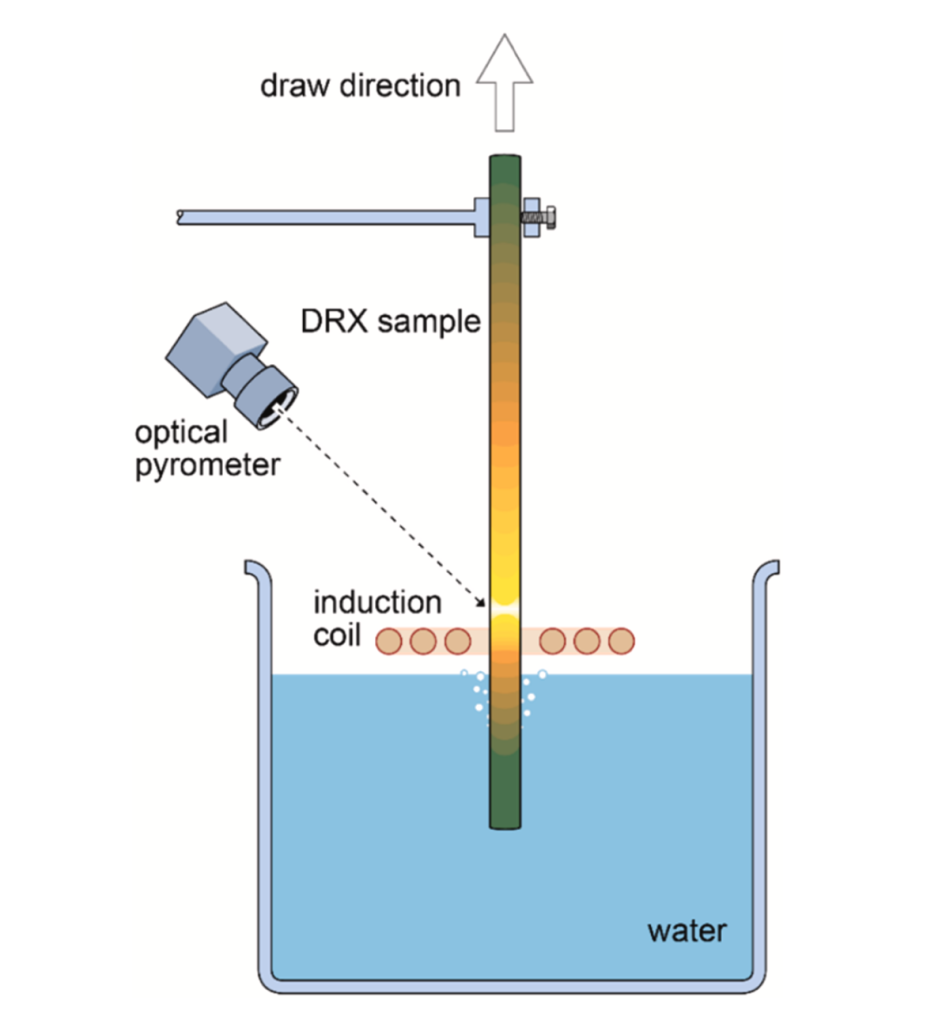

The analysis workforce’s new warmth remedy method is a type of directed recrystallization. This warmth remedy method passes a fabric, on this case laser powder mattress fusion 3D printed IN738LC rods, via an induction coil at managed speeds to meld the supplies’ microscopic grains into bigger, stronger, and extra uniform crystalline buildings.

Throughout testing, every rod was slowly drawn from a water bathtub and thru the coil at various speeds, heating the steel to between 1,200℃ and 1,245℃ within the course of. Every pattern was drawn via the ‘scorching zones’ at charges starting from 1 mm/hr to 100 mm/hr.

The researchers in the end discovered that drawing the rods at 2.5 mm/hr at temperatures of 1,235℃ created a steep thermal gradient which triggered an optimum transformation within the supplies 3D printed microstructure.

Following the heating course of, the workforce examined the microstructure utilizing optical and electron microscopy. These observations confirmed that the microscopic construction on the floor of the 3D printed steel half possessed columnar grains possessing vastly improved anti-creep properties.

“The fabric begins as small grains with defects known as dislocations, which are like a mangled spaghetti. If you warmth this materials up, these defects can annihilate and reconfigure, and the grains can develop,” added Cordero. “We’re repeatedly elongating the grains by consuming the faulty materials and smaller grains — a course of termed recrystallization.”

What’s extra, it was additionally discovered that particular grain measurement and orientation might be achieved by altering the draw pace and temperature of the rod samples. This stage of management is nicely suited to industrial producers who want to 3D print steel parts which possess particular structural properties.

Certainly, the researchers argue that this course of will enable producers to manufacture new, optimized blade and vane geometries for extra energy-efficient land-based fuel generators and jet engines.

Publish-processing in steel 3D printing

Some of the broadly used steel 3D printing processes, Laser powder mattress fusion 3D printing can produce steel elements that possess pores and keyholes within the steel half. These structural traits weaken the energy of the 3D printed steel half.

HIP publish processing is often used to counteract these deficiencies. This course of, not like that of the MIT workforce, applies excessive temperatures reaching 2000℃ and isostatic pressures of as much as 200MPa to the 3D printed steel elements. HIP reduces the porosity of the supplies inner construction, bettering the bodily properties of the half within the course of.

In 2019, German 3D printing service supplier FIT Additive Manufacturing Group (FIT AG) acquired a HIP system from Swedish high-pressure expertise skilled Quintus Applied sciences. This method is being leveraged to make sure that, after publish processing, the corporate’s 3D printed steel elements move high quality assurance checks.

“We now have evaluated the necessities of 250 worldwide industrial prospects for 5 years, and HIP turned out as a solution to many high quality points,” commented Carl Fruth, CEO FIT AG. “The outcomes that may be achieved by combining AM and HPHT are extremely encouraging. It’s past all query that our prospects will profit strongly by this partnership.”

Publish-processing can also be regularly used to enhance the floor end of a 3D printed steel half. Elsewhere, Vermont-based steel additive manufacturing firm A3DM Applied sciences, and Spanish superior expertise agency GPA Innova, have partnered to advance post-processing of additively manufactured steel elements. This collaborative analysis settlement sees the 2 corporations develop optimized course of parameters for GPA Innova’s “DryLyte” dry electro-polishing course of for steel alloys utilized in powder-based 3D printing.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. You too can observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of obtainable roles and kickstart your profession.

Featured picture exhibits MIT’s steel 3D printing post-processing testing stage. Picture through Dominic David Peachy/MIT.