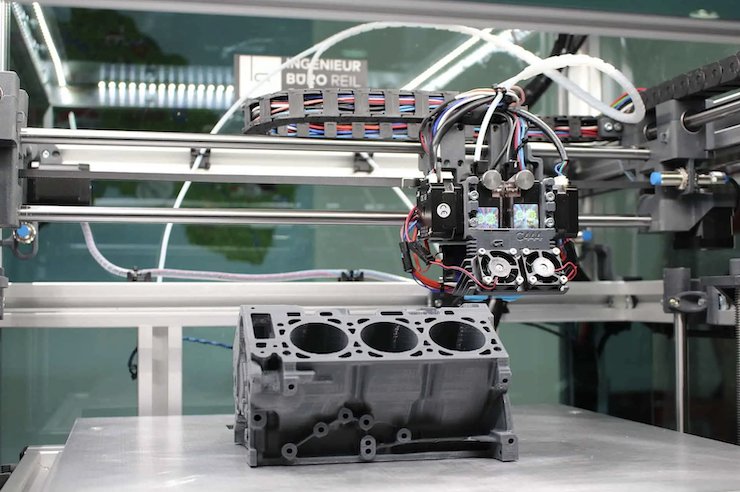

This text is aimed toward offering insights into the 3D printing of business items and gear, and the way additive manufacturing has emerged as a superb substitute for CNC machining.

The fast, revolutionary and ease of operation of additive manufacturing makes it one of many go-to choices to fabricate industrial items and gear. The commercial items class embody the manufacturing of equipment and tooling utilised within the manufacturing of different items.

This section often employs standard manufacturing applied sciences like CNC machining which incur a number of price and time, 3D printing can function an addition or instead to traditional machining within the discount of prices and time.

Why 3D printing in industrial items?

Prototyping

No matter the sphere, 3D printing is arms down the most effective know-how for prototyping. Industrial items manufacturing entails some huge cash that goes into analysis, growth the place it undergoes a number of iterations from the preliminary design part to the ultimate manufacturing part.

With the intention to minimize prices and sustain with the market demand, the method needs to be low-cost and fast 3D printing, additionally known as speedy prototyping, is right for this goal.

Design complexity and innovation

Additive manufacturing can produce parts with fewer design restrictions which can be powerful to provide utilizing conventional manufacturing processes. This design flexibility paves a method for innovation by making it potential so as to add improved functionalities like decrease weight (via lattice constructions), and complicated geometries that aren’t potential via conventional processes.

Moreover, new AM applied sciences are more and more in a position to produce multi-material printed elements with particular person properties similar to electrical conductivity and variable energy. These AM processes play an essential position in creating safer, lighter, sooner and extra environment friendly machines of the longer term.

On-demand manufacturing

Additive manufacturing facilitates on-demand manufacturing of any product with a managed price construction and glued lead time, which considerably improves the speed of producing by decreasing the time to design and launch a product.

Yet one more benefit is, new and outdated units will be simply produced with a number of 3D printing supplies and to the specified quantity immediately from a producer’s digital stock or a buyer’s CAD mannequin. This transforms the availability chain and permits producers to immediately meet the calls for.

Purposes of 3D printing in industrial items

Tooling

One of many chief functions of 3D printing within the industrial sector is tooling which entails the printing of sunshine and sturdy jigs, fixtures, gauges. Injection moulding dies may also be simply manufactured with the assistance of metallic 3D printing. Loads of time and design iterations go into this die making. However with the power of 3D printing to attain complicated designs, standard patterns in mould cooling will be changed with superior cooling channels which displays within the effectivity by bettering the cooling mechanism of the mould.

Finish-use elements

Steel 3D printing together with polymer 3D printing has already proved their value out there. Many sectors like automotive and aerospace have already began utilizing additive manufacturing of their operations due to the lowered lead time and low price in prototyping. Automotive big Porsche has began manufacturing engine pistons with 3D printing.

Swiss aerospace firm RUAG has used 3D printing in optimising its current satellite tv for pc bracket design, thereby launching 3D printing even into area.

Spare half manufacturing

With the assistance of CAD, designs for actually all elements will be saved as a digital copy in a pc exhausting drive thereby eliminating the necessity to preserve a list. With the usage of 3D printing, a spare half might probably be produced on-demand. The accessibility of the know-how will encourage suppliers to open up new areas to offer a simple provide of 3D printed parts and spare elements.

Even elements that now not exist will be remade to requirement, on reverse-engineered primarily based on digital scans of current elements. Older designs could discover themselves with a brand new lease of life and on the opposite facet, spare elements of basic vehicles will be reproduced simply.

Conclusion

Xometry affords quick, dependable, and extremely correct 3D printing providers for thermoplastics, elastomers, and metals which can be of immense profit to industrial firms. As well as, Xometry additionally affords varied post-processing operations to make sure the utmost high quality.

No matter amount, precision, complexity, and required supply time, Xometry all the time has the manufacturing capability to ship. Head to Xometry’s on the spot quoting platform to add your fashions and obtain a quote in seconds, completely free.