As 2023 got here to an in depth, 3D printing information noticed developments in a variety of verticals. The Protection business continued to leverage additive manufacturing, which is about to allow a file turnaround for the following era Tempest fighter jet.

All of the 3D Printing Business Information from 2023.

Elsewhere, 3D printing materials upcycling capabilities alleviated provide chain challenges, and corporations developed new high-performance supplies.

2023 noticed quite a few 3D printing developments inside the medical sector, and December was no completely different. 3D printed spinal implants acquired market approval in China, while developments had been made in 3D medical imaging.

Learn on for extra December 3D printing information highlights from the likes of Stratasys, Siemens Healthineers, Additive Manufacturing Options Ltd., 6K Additive, Constellium, Nikon SLM Options, Mechnano, Lithoz, and Vivid Laser Applied sciences.

Report fighter jet improvement time enabled by AM

December marked a key improvement within the World Fight Air Programme (GCAP), which is creating a subsequent era supersonic fighter jet known as the Tempest.

First initiated in December 2022, GCAP has merged Japan’s F-X program with the UK and Italy’s Workforce Tempest mission. This newest improvement noticed the signing of a world treaty between the three nations which confirmed that the UK will host the GCAP authorities HQ.

GCAP guarantees an extremely small improvement time for the Tempest, with the finalized fighter jet to be delivered in 2035, 12 years after the signing of the trilateral settlement. Compared, the Eurofighter Hurricane was developed over 20 years, while Lockheed Martin’s F-22 Raptor underwent a 26-year improvement interval.

Given the numerous lead time reductions supplied by additive manufacturing, 3D printing is about to play a key function in GCAP. BAE Methods, a number one industrial companion of GCAP, has outlined the intention to 3D print 30% of the Tempest’s components.

The Program’s different main companions, Italian protection contractor Leonardo, and Japanese producer Mitsubishi Heavy Industries (MHI), additionally possess sturdy backgrounds in additive manufacturing. Leonardo had beforehand partnered with large-format 3D printer producer BigRep to 3D print parts for the Royal Navy’s AugustaWestland AW101 helicopters. Moreover, MHI provides its personal proprietary LAMDA directed vitality deposition (DED) 3D printers.

Securing materials provide chains

2023 has seen geopolitical and macroeconomic challenges place vital strain on international provide chains. To fight this, additive manufacturing has been more and more utilized to safe the provision of key supplies.

In December, Industrial 3D printing supplies producer 6K Additive was awarded a $23.4 million grant from the US Division of Protection (DoD).

The corporate plans to make use of this funding to double capability and develop its home metallic upcycling capabilities to create, preserve, shield, and restore US industrial base capabilities for warfighting.

Awarded by way of Protection Manufacturing Act (DPA) authorities, this funding will assist to reshore the provision of high-grade metals equivalent to titanium, nickel and refractory metals inside the US. These supplies are steadily used to fabricate plane structural parts, turbine engine blades, rocket engines, and radar techniques.

Furthermore, this grant will assist 6K’s plans to renovate its amenities, purchase new expertise, set up new tools, and improve its engineering capabilities.

Elsewhere, UK-based 3D printing SME Additive Manufacturing Options Ltd. (AMS) introduced a collaboration with the UK Ministry of Defence’s(MoD) Defence Tools Gross sales Authority (DESA).

This partnership will see AMS analysis the feasibility of recovering and recycling crucial supplies from surplus protection property. This marks the primary stage of an MoD mission that seeks to boost data and management over present and future materials sourcing methods.

In the end, the MoD hopes to create a robust UK-based provide chain for key minerals, equivalent to titanium, to the UK market.

“AMS has tirelessly constructed momentum and experience inside the additive powder market, with a pointy deal with offering recycled feedstocks. This settlement represents the following part in our mission to commercialize recycled supplies inside the additive manufacturing feedstock market,” commented AMS Director and CEO Rob Higham.

“Supporting the MoD in addressing crucial mineral accessibility and functionality is an honor and a testomony to the efforts of your entire AMS staff.”

Excessive-performance 3D printing supplies

December additionally noticed notable developments inside the excessive efficiency 3D printing materials area. Arizona-based 3D printing firm Mechnano and Bomar launched a brand new E35B+ masterbatch using Bomar’s BR-952 oligomer.

The masterbatch employs unique D’Func (Discrete, Dispersed, and Functionalized Carbon Nanotubes) know-how to facilitate the development of 3D printing resin. This new providing is alleged to make sure heightened mechanical energy and uniform electrical efficiency.

Following the launch of E35B+, Mechnano and Bomar launched a further resin 3D printing materials dubbed T50B masterbach. Additionally developed with Mechnano’s D’Func know-how, this materials concentrates on Discrete, Dispersed, and Functionalized Carbon Nanotubes. T50B has been designed to boost mechanical properties and preserve constant electrical efficiency on the nanoscale inside the resin.

December additionally noticed aluminum specialist Constellium develop its Additive Manufacturing Improvement plan by means of a partnership with Nikon’s subsidiary Morf3D.

Searching for to handle demand for large-format metallic 3D printing, this partnership facilities across the qualification and improvement of Constellium’s Aheadd CP1 powder utilizing Nikon SLM Options’ SLM 500.

Optimized for laser powder mattress fusion (L-PBF), The Aheadd CP1 is an aluminum-iron-zirconium powder designed to boost manufacturing throughput and decrease upfront materials prices. Key to this powder is its excessive energy and ductility, distinctive thermal and electrical conductivity, environment friendly processing, and simplified post-processing procedures.

Developments in healthcare

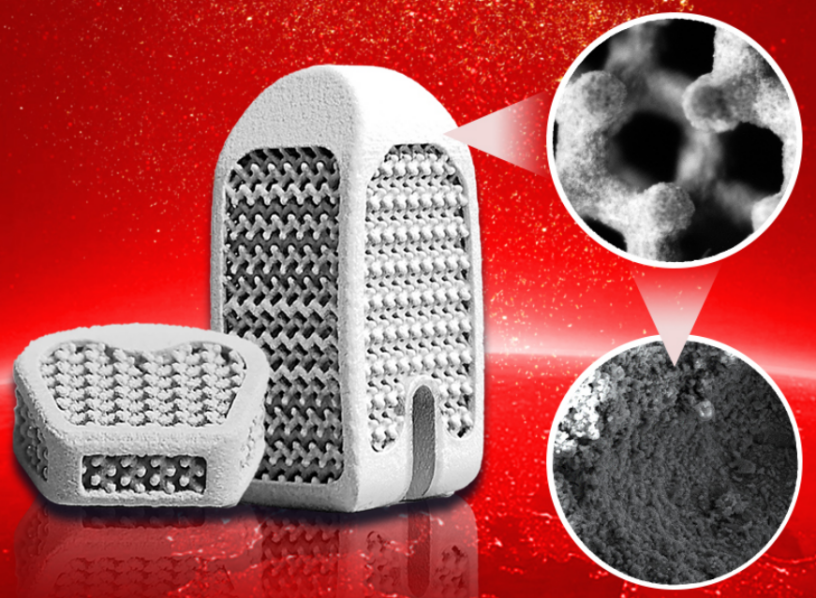

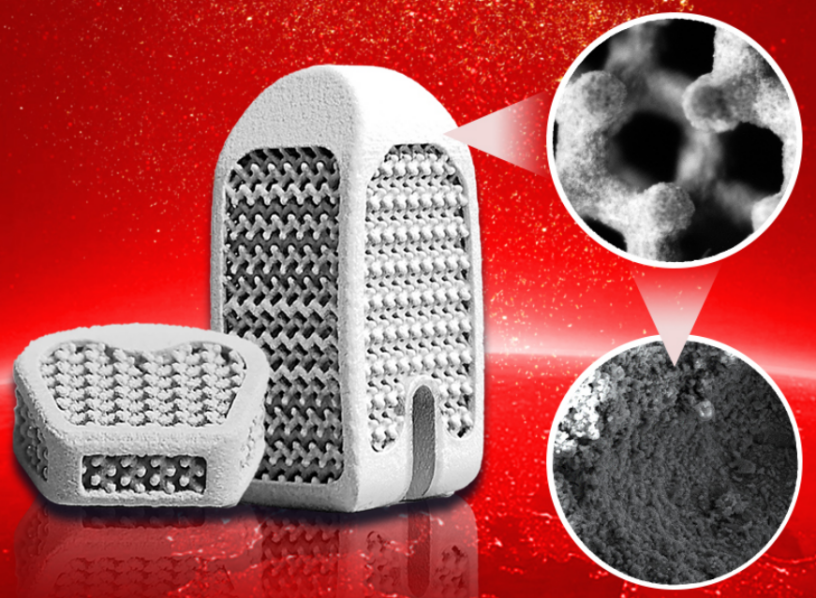

Medical developments inside additive manufacturing continued into December, with a 3D printed spinal cage from medical agency Wedo Bio-Medical Know-how Co, Ltd. receiving market approval in China.

The corporate’s WedoCage, a Hydroxyapatite-Coated Porous Titanium Alloy Interbody Fusion Machine, was 3D printed utilizing the BLT-S210 and BLT-S310 techniques from Vivid Laser Applied sciences (BLT).

The WedoCage includes a complicated porous construction requiring excessive precision throughout 3D printing. In reality, the spinal implant incorporates in depth overhangs and difficult product course of parameters and assist buildings. Subsequently, BLT labored intently with Wedo’s R&D staff to iterate and optimize the 3D print parameters of the WedoCage.

The 3D printed implant has already undergone managed scientific trials in China over 10 analysis hospitals. This examine discovered that WedoCage’s fusion efficient charge was 97.10%, surpassing the 85.29% fusion succession charge of different PEEK Fusion Units. No device-related adversarial reactions had been reported in the course of the trial.

Elsewhere, main 3D printer producer Stratasys partnered with Siemens Healthineers to advance medical imaging phantoms utilized in computed tomography (CT) scans.

This partnership goals to develop phantoms with ultra-realistic human anatomy traits. Such developments may result in the substitution of 3D printed buildings for human cadavers in sure contexts. This may improve effectivity and cut back human variability throughout testing and calibration processes.

“The present limitations of imaging phantoms have been a longstanding problem for the radiology neighborhood,” commented Erez Ben Zvi, Vice President Medical at Stratasys. “This partnership with Siemens Healthineers will allow us to collectively discover the huge potentialities of our radiopaque supplies and 3D printing applied sciences to beat these obstacles.”

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information. You may as well observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture exhibits an artist’s impressions of the GCAP fighter jet. Picture by way of BAE Methods.