Powder dealing with gear producer Volkmann GmbH is to supply a brand new line of closed-loop and stand-alone, automated metallic powder administration methods particularly designed for integration with EOS metallic additive manufacturing (AM) methods.

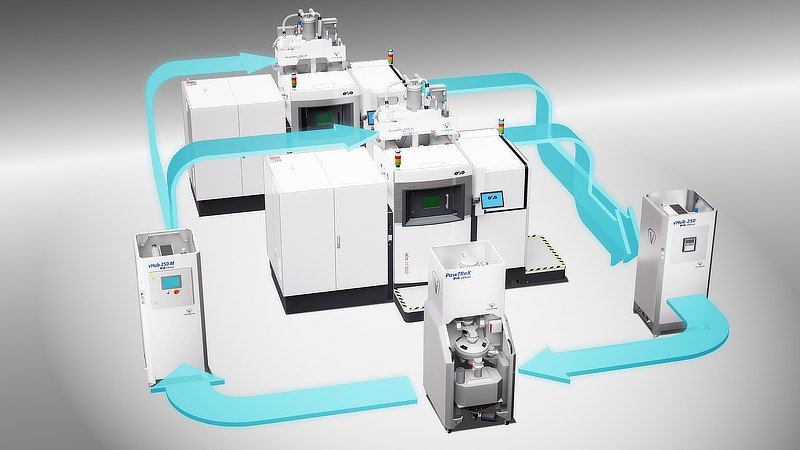

The partnership with the economic 3D printer producer will see EOS Version powder dealing with methods supplied for its EOS M 400 sequence machines. The central metallic powder administration methods can be utilized to mechanically management the switch and loading of fabric from storage into 3D printers, for capturing and sieving of extra powder for reprocessing, and automatic vacuum drying of powders. Buffer storage models and different equipment are additionally accessible with the brand new methods. The EOS Version can function unattended, 24/7 as a totally enclosed, sealed circuit to remove metallic mud from the office, shield employees from potential publicity, and shield metallic powders from ambient moisture and contamination.

“Our new methods present EOS end-users with an entire, plug-and-play, automated powder dealing with resolution that may scale as their manufacturing wants improve,” says Christian Mittman, director of superior options for Volkmann. “This can be a logical subsequent step in our shut relationship with EOS, and one which we really feel will profit EOS prospects with quicker, safer, extra dependable printing and persistently prime quality printed elements.”

Again in October, EOS introduced its new EOS M 300-4 1kW 3D printer, because of be commercially accessible in February, might be supplied alongside the Volkmann PowTrex EOS Version powder dealing with system to ‘additional optimise’ its workflow.