Developments within the medical sector dominated 3D printing information in August 2023. All through the month, 3D Printing Trade reported on various developments which leverage additive manufacturing to deal with long-term well being circumstances.

All of the 3D Printing Information from 2023

Elsewhere, fervent acquisition and merger exercise continued into August, while a number of corporations demonstrated the sustainability advantages provided by 3D printing. Formnext + PM South China 2023 concluded August with a showcase of rising additive manufacturing improvements.

Learn on for key August 2023 3D printing information highlights from Apple, Triastek, 3D Methods, Stratasys, Desktop Metallic, Xerox, ADDiTEC, Manufactura, Farsoon Applied sciences, Shiny Laser Applied sciences, INTAMSYS, and extra.

3D printing improvements within the medical sector

Main 3D printer producer 3D Methods continued its long-term regenerative drugs efforts in August by asserting a strategic partnership with biopharmaceutical agency Theradaptive.

By means of this collaboration, the businesses are integrating Theradaptive’s protein-engineering expertise with 3D Methods’ 3D printed orthopedic implants. It will allow localized supply of implants, optimizing therapeutic outcomes for sufferers and signifying a notable step within the regenerative drugs house.

“Uniting these two world-class applied sciences guarantees to offer safer and more practical therapy choices for sufferers who at the moment have few choices,” commented Luis Alvarez, CEO and founding father of Theradaptive. “This partnership units the stage for a lot of new merchandise that may have the potential to considerably enhance affected person care.”

Chinese language drug 3D printing agency Triastek introduced the conclusion of the primary First-in-Human (FIH) examine of its 3D printed drug, dubbed T21. This drug is designed to deal with reasonable to extreme ulcerative colitis. The tablets are produced utilizing the corporate’s Soften Extrusion Deposition (MED) course of. This enables for exact management of the drug’s launch within the gastrointestinal tract.

Scientists from the College of Sydney and the Youngsters’s Medical Analysis Institute (CMRI) collaborated to 3D print purposeful human tissues that mimic an organ’s structure. Leveraging 3D photolithographic printing, the researchers utilized a mixture of bioengineering and cell tradition strategies to instruct stem cells to change into specialised.

By producing microscopic mechanical and chemical alerts, the scientists instructed the cells to kind correct organ-like constructions. This method was used to create a bone-fat meeting that resembles bone construction, and an meeting of tissues that resemble processes throughout early mammalian improvement.

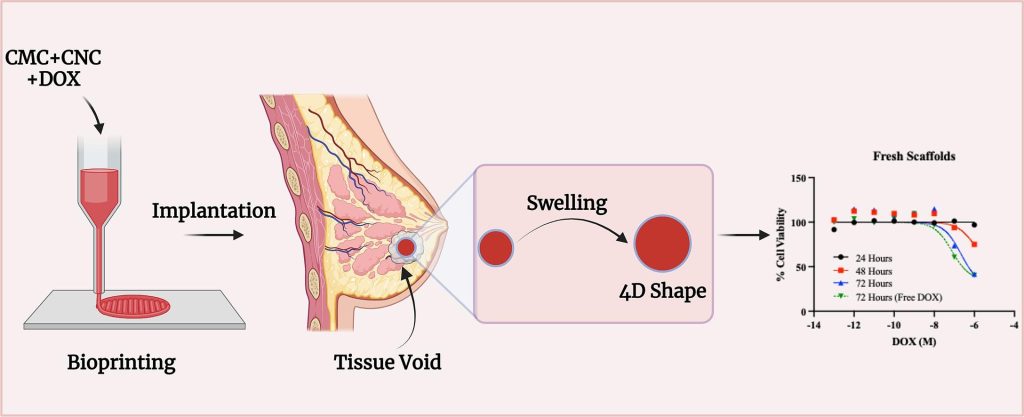

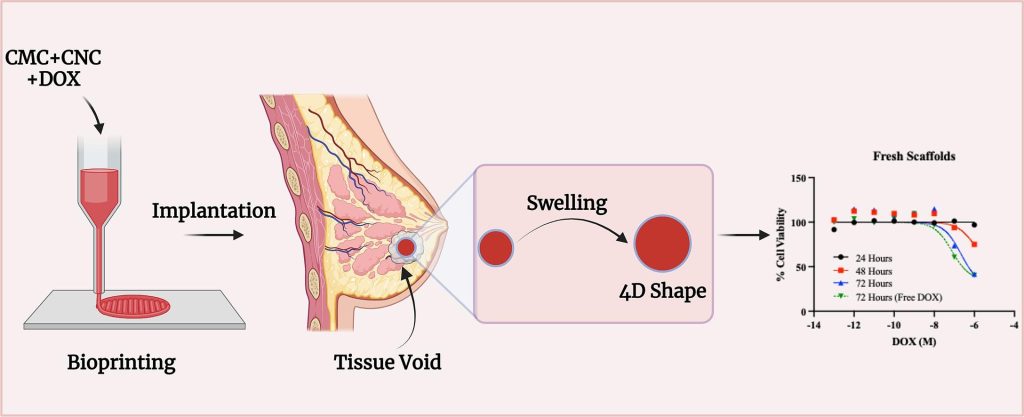

Elsewhere, researchers from Queen’s College Belfast developed 4D printed breast implants to deal with breast most cancers. This was mentioned to be the primary time 4D printing has been used to provide breast implants.

Due to using “good supplies” that may change morphology after 4D printing, these implants may be programmed to vary measurement to higher match right into a affected person’s tissue cavity. Moreover, the 4D printed implants can launch chemotherapy medicine immediately on the level of want.

Merger and acquisition exercise

Merger and acquisition developments once more prevailed within the 3D printing information cycle. The saga between Stratasys, 3D Methods, Nano Dimension, and Desktop Metallic continued into its fourth consecutive month in August.

While it had been anticipated {that a} deal can be struck between 3D Methods and Stratasys, the publication of the 2 corporations Q2 2023 monetary outcomes advised a special story.

“Whereas we had hoped to be ready to announce a cope with Stratasys as we speak, we’re not ready to take action,” said Dr. Jeffrey Graves, President and CEO of 3D Methods, throughout a name with buyers. “Candidly, we anticipated this transaction to be introduced by now and are pissed off by the tempo and the shortage of any engagement on the merger settlement.”

Furthermore, Nano Dimension withdrew its plan to amass Stratasys, leaving Desktop Metallic as the one different participant on this multi-company battle. In direction of the top of the month, the Stratasys and Desktop Metallic merger appeared nearer to fruition, as a date was set for a “Desktop Metallic particular assembly.”

Scheduled for September 28, the assembly would convey collectively Stratasys shareholders to vote on the proposed mixture of the 2 corporations. Learn the September version of our 2023 evaluation of the 12 months collection to study the result of this vote.

Elsewhere, World print and digital doc company Xerox offered its additive manufacturing enterprise unit, Elem Additive Options, to US-based steel additive manufacturing firm ADDiTEC. The choice to relinquish its 3D printing capabilities got here as the corporate appeared to refocus its strategic priorities and investments on its core print, IT and digital companies.

Sustainability and 3D printing

Sustainability was one of many key buzzwords in 2023, and August noticed its justifiable share of sustainability 3D printing information.

World commerce group Additive Producer Inexperienced Commerce Affiliation (AMGTA) introduced the preliminary outcomes of a steel 3D printing life-cycle evaluation (LCA). This examine highlighted that binder jetting reduces carbon emissions by 38%, when in comparison with conventional steel casting strategies.

The LCA was performed by the Yale Faculty of the Surroundings(YSE) in collaboration with 3D printer producer Desktop Metallic. The manufacturing of a metal scroll chiller utilizing an HVAC system from Trane Applied sciences was used to judge the environmental influence of binder jet 3D printing. In response to the examine, the numerous discount in greenhouse gasoline emissions was pushed by lowered power demand in the course of the manufacturing part.

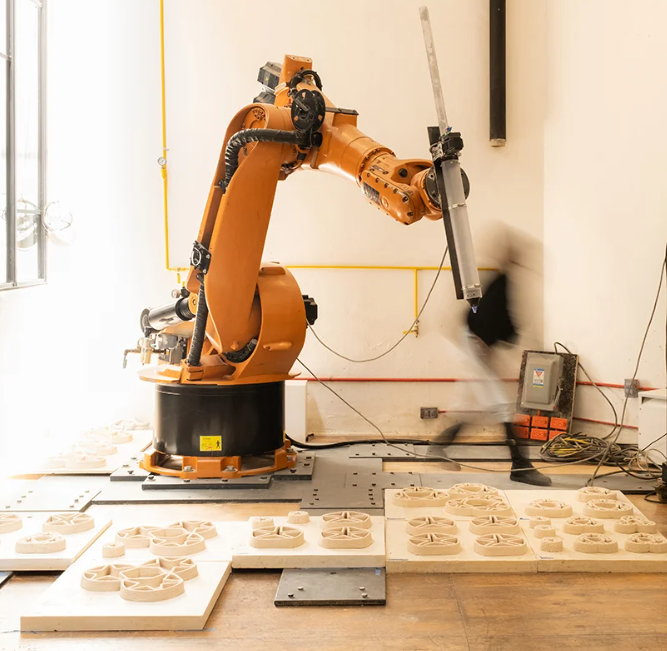

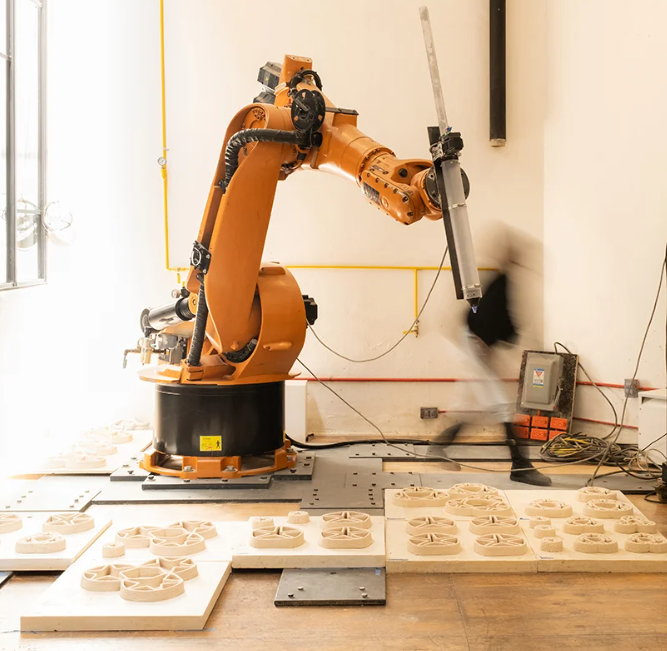

Mexico-based Manufactura partnered with furnishings manufacturing and design workshop La Metropolitana to 3D print sustainable constructions utilizing recycled wooden. The initiative, titled “The Wooden Undertaking” or “UN PROYECTO DE MADERA,” makes use of La Metropolitana’s every day manufacturing of 5-6 luggage of sawdust, weighing 40 kg every.

Using an extruder mounted on a KUKA KR-150 industrial robotic arm, the crew 3D printed three architectonic-scale partition wall check items. These items are reportedly straightforward to copy and assemble, and may be sustainably produced in a round method with waste-sourced uncooked supplies from La Metropolitana.

Elsewhere, researchers from the College of Tokyo introduced a novel technique of speedy 3D object fabrication. This distinctive 4D printing technique self-folds temperature-sensitive materials into advanced 3D shapes. In contrast to standard 3D printing processes which regularly generate intensive waste supplies, this course of is reportedly waste-free. The researchers view trend design as a key utility of this new expertise. Certainly, the style business usually grapples with materials wastage, particularly within the manufacturing of bespoke designs.

Formnext + PM South China 2023

In August, 3D Printing Trade traveled to Shenzhen to attend Formnext + PM South China 2023. This 12 months’s occasion noticed 275 corporations showcase their manufacturing expertise, a 3rd of which have been devoted solely to 3D printing.

Through the present, China-based binder jet 3D printer producer EasyMFG drew a whole lot of consideration by showcasing 3D printed smartwatch casings. 3D printed in 316L chrome steel utilizing its binder jetting expertise, the casings reportedly endure 18-20% shrinkage after they’ve been sintered.

This showcase highlights rising curiosity in using additive manufacturing for serial and mass manufacturing of shopper items. In August, various 3D printing information reviews indicated that World shopper electronics firm Apple Inc. is leveraging steel 3D printers from Farsoon Applied sciences and Shiny Laser Applied sciences to provide key parts for its smartwatches.

Equally, the present noticed Farsoon display key tooling functions for the injection molding sector. In truth, 80% of vape pens/e-cigarettes in China are actually produced utilizing 3D printed molds.

Within the supplies house, Formnext + PM South China noticed Kexcelled unveil its new high-speed filament. Designed and examined for Bambu Labs’ 3D printers, this filament can reportedly function at as much as 500 mm/s.

Elsewhere, SoonSer unveiled its large-format Mars Professional 600 SLA 3D printer, while Kings 3D Printing reported the sale of over 10,000 3D printers. Shanghai-based INTAMSYS reported that it had offered over 1,000 items of its Funmat Professional 310 FDM 3D printer, with gross sales boosted by the China tech schooling sector.

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture reveals the Shenzhen World Exhibition and Conference Heart, the place Formnext + PM South China was held. Photograph by Michael Petch.