October 2023’s 3D printing information noticed quite a few novel functions throughout the style trade, with the launch of two new 3D printed footwear merchandise. The personalised healthcare sector additionally continued to develop, with 3D Methods increasing its 3D printed medical portfolio.

Extra 3D Printing Business Information from 2023.

Elsewhere, efforts to scale additive manufacturing noticed a number of firm’s goal serial and mass manufacturing with 3D printing. Furthermore, because the battle in Ukraine moved into its second yr, industrial additive manufacturing corporations provided 3D printers to the area to assist the nation’s warfare effort.

Learn on for extra highlights from Adidas, Carbon, HP, Stratasys, Odapt, Evolve Additive Options, SPEE3D, Essentium, and extra.

3D printing: a rising development within the Trend sector

The style sector dominated October’s 3D printing information. World sports activities gear agency Adidas constructed on its rising 3D printed footwear portfolio with the launch of the MC87 4D, a limited-edition spikeless golf shoe. The MC87 4D incorporates a novel 3D printed midsole produced with US 3D printer OEM Carbon’s Digital Gentle Synthesis (DLS) know-how.

This midsole incorporates a lattice construction designed to offer optimized vitality absorption. This effectively delivers vitality again to the foot whereas offering essential assist the place it’s wanted, the corporate claims.

October additionally noticed multinational printing agency HP announce a partnership with Brooks Operating to develop the Exhilarate-BL trainers with 3D printing. This new working shoe introduces 3DNA, a 3D printed midsole that gives a propulsive, springy really feel.

3D printed utilizing HP’s Multi Jet Fusion (MJF) 3D printing know-how, the corporate claims that the midsole outperforms 90% of different midsoles available on the market. Brooks introduced a restricted launch of the shoe to pick Put on Testers and Run Membership members. It’s hoped that this can support future 3DNA shoe designs utilizing runner information like stride size and cadences.

Away from the footwear market, famend designer Jayne Pierson made an impression at London style week together with her “Ceridwen” assortment which leverages Stratsys’ 3DFashion know-how. Pierson showcased quite a few wearable items that combine 3D printed components into the material of the designs.

US-based 3D printer producer 3D Methods launched its new MJP 300W 3D printer and VisiJet Wax Jewel Ruby materials to handle the rising international jewellery market. These new choices reportedly permit customers to effectively obtain larger design freedom and improved floor end on their wax jewellery items.

Personalised healthcare

Plenty of developments have been as soon as once more made throughout the area of personalised healthcare. 3D Methods’ point-of-care applied sciences continued to develop, with the manufacturing of a patient-specific 3D printed cranial implant for a process on the College Hospital Basel in Switzerland.

This announcement was important because it marked the creation of the primary cranial implant produced on the level of care that complies with present Medical Gadgets Laws (MDR). As such, 3D Methods is effectively positioned to use the rising cranial implant market, which is projected to succeed in $2.1 billion by 2030.

Elsewhere, Pharmaceutical customization know-how developer CurifyLabs launched Good Manufacturing Apply (GMP) developed Pharma Inks. These new 3D printable pharmaceutical inks are optimized for the on-site manufacturing of patient-tailored and personalised medicines in pharmacies and hospitals.

Conventional guide compound processes will be time-consuming and error inclined. CurifyLabs’ new providing reportedly overcomes these challenges by automating the manufacturing of personalized drugs. GMP Pharma Inks supplies pharmacists with direct entry to a library of 3D printable inks and a 3D printer, making certain quick and compliant drug manufacturing.

In October, 3D Printing Business sat down with Ivana Llobet, CEO and co-founder of Odapt, to study extra concerning the firm’s personalised 3D printed ostomy luggage. These customizable merchandise are stated to supply a superior match and a sustainable resolution to a prevalent medical want.

In keeping with Llobet, 3D printing gives notable benefits within the manufacturing of ostomy luggage. “Folks could possibly be anyplace on the earth, and we might print it regionally of their international locations and ship it to them.” Odapt is now concentrating on a medical trial in Barcelona, indicating a strategic method in direction of a business launch.

Scaling manufacturing in Additive manufacturing

Efforts to scale up 3D printing to fulfill serial and mass-manufacturing wants have been prevalent in October. Minnesota-based 3D printer producer Evolve Additive Options introduced a strategic partnership with German 3D printing service supplier alphacam GmbH to fulfill excessive manufacturing calls for with 3D printing.

This partnership sees alphacam supply elements manufactured utilizing Evolve’s Thermoplastic Electrophotographic (STEP) know-how to European prospects. Launched in 2017, STEP know-how allows high-speed 3D printing of engineering-grade thermoplastics.

STEP is reportedly 50 occasions sooner than SLS 3D printing, permitting for prime throughput “toolless” manufacturing. alphacam adopted Evolve’s Scaled Quantity Manufacturing (SVP) platform to ship excessive portions of totally dense, high-fidelity thermoplastic elements.

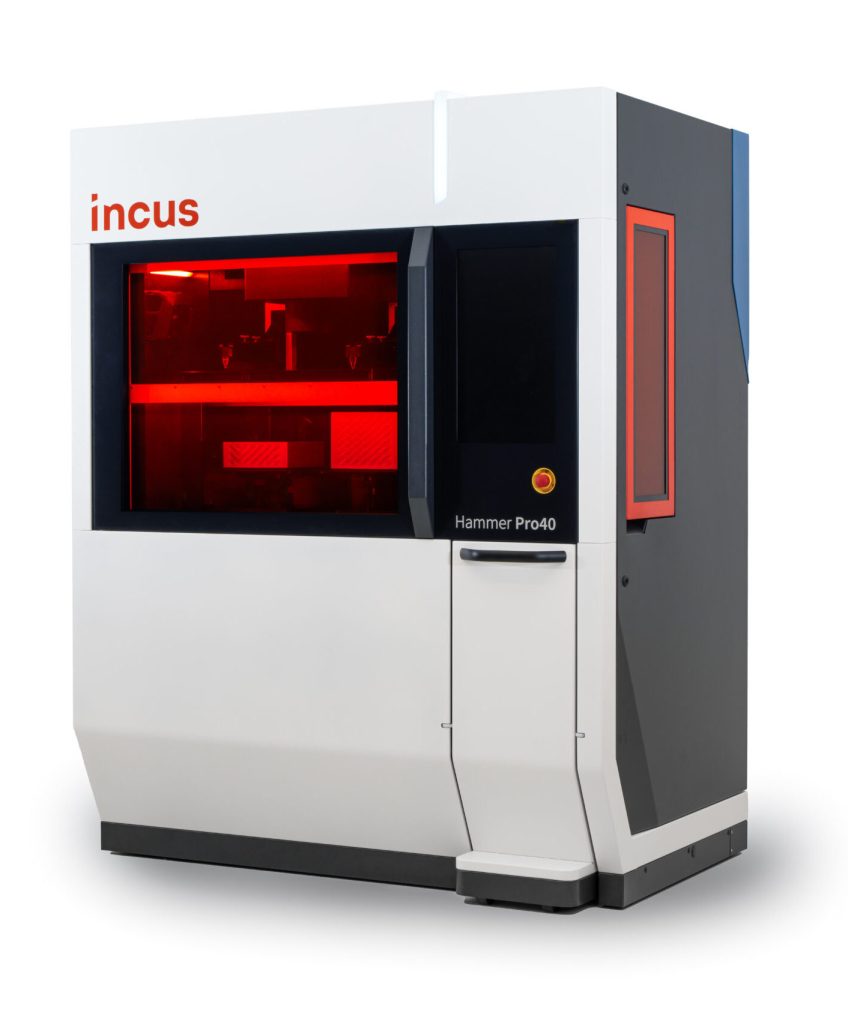

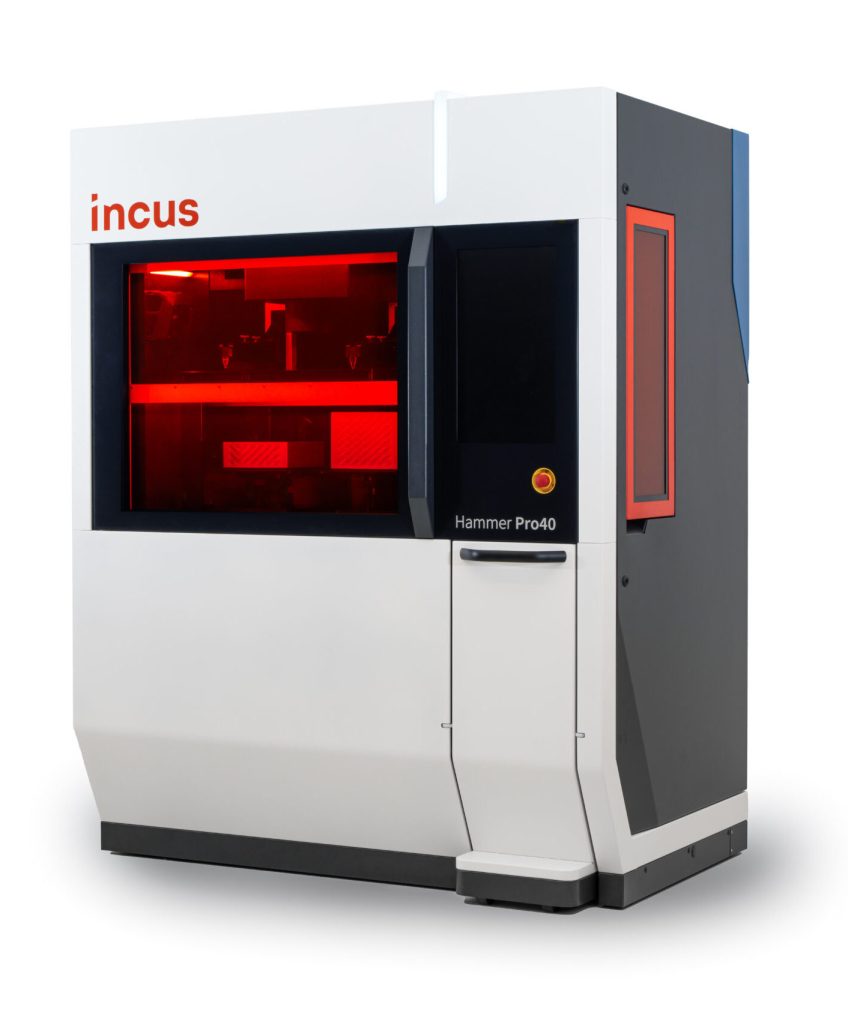

Elsewhere, Austrian engineering agency and OEM Incus GmbH launched the Hammer Pro40, a Lithography-based Metallic Manufacturing (LMM) 3D printer designed to fulfill calls for in mass manufacturing. The Hammer Pro40 gives optimized manufacturing capabilities, and will be deployed instantly on the manufacturing facility ground.

Incus claims that its new 3D printer combines “unmatched value effectivity” with high-quality 3D printing. The Hammer Pro40 gives a considerable 3D printing pace of as much as 240 layers/h and as much as 700 cm3/h. What’s extra, the 3D printer reportedly has a price per cm3 that’s 4 occasions decrease than its predecessor, the Lab35.

“The Hammer Pro40 was strategically developed to satisfy the rising demand for mass manufacturing with AM whereas nonetheless delivering the distinctive options of our know-how,” acknowledged Incus CEO, Dr Gerald Mitteramskogler.

Bolstering Ukraine’s protection capabilities with AM

Calum Stewart, Director of Protection Packages at Australian steel 3D printer producer SPEE3D, spoke with 3D Printing Business to debate the corporate’s efforts to provide seven WarpSPEE3D 3D printers to Ukraine. A part of a US Division of Defence’s (DoD) Ukraine Safety Help initiative, this venture additionally noticed the Victoria-based firm prepare quite a few Ukrainian troopers and engineers in the usage of its chilly spray know-how.

In keeping with Stewart, SPEE3D’s know-how allows Ukrainian troops to shortly manufacture “elements of consequence” on the level of want. The important thing objective for SPEE3D in Ukraine is to make sure that there’s “extra gear within the battle, extra of the time,” Stewart acknowledged. “It’s good to be a 3D printing firm that’s truly doing one thing we predict is making a distinction.”

One other 3D printing firm that provided additive manufacturing know-how to the Ukrainian navy is Industrial 3D printer producer Essentium. The corporate partnered with KVG to offer the nation with industrial 3D printers, coaching, and manufacturing instruments. Simply 96 hours after approval, the 2 corporations had efficiently deployed superior Excessive-Velocity Extrusion (HSE) 3D printers throughout a number of areas in Ukraine.

“This collaboration bridges the hole between 3D printing and conventional manufacturing to permit Ukraine to create important parts in real-time, improve area effectiveness, and strengthen the warfighter’s capabilities,” commented Essentium CEO Blake Teipel.

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals the Adidas MC87 4D golf shoe. Photograph through Adidas.